On/off-road tires must strike a compromise between traction, durability and longevity. "Fuel efficiency, tread life, casing durability and other factors can have a direct impact on operating cost," says Chris Tolbert, business segment manager, Michelin Americas Tires. "By selecting the best tire for the application, on/off-highway fleets can ensure their operating costs remain low."

Many different types of tires are available. "There are all-position tires - capable of being used in steer, drive or trailer positions - and tires made specifically to give better traction in drive positions," notes Tim Miller, Goodyear Tire & Rubber.

Yet, a common mistake is assuming one or two different tires will fill the needs of every truck in the fleet. "If some trucks travel frequently on the highway and others are mainly off road," Millers notes, "the same tire, or tires, might not deliver the best performance (tread wear and durability)."

Match to operating conditions

It's all about choosing the most appropriate tool for the job. "Most people don't try to pound a nail with a screwdriver, and neither should they expect good results if selecting the wrong tires," Tolbert asserts. "On/off-road tires face specific challenges and dangers that must be addressed in the tire design and construction to make sure the tire's life and performance will be maximized."

Consider the percentage of time the vehicle will spend on- and off-highway. "A tire that is designed mainly for off-highway use will wear more quickly than an over-the-road tire when the vehicle is used in mainly highway situations," Miller states.

Also evaluate the type of terrain or application the tire will experience off road. "Knowing the type of environment will help determine the level of traction that is needed for the vehicle to operate," says Tolbert. "This information will also dictate the amount of tread and sidewall protection the tire will need to stay up and running. The on/off-road tire should also have a compound designed to combat the aggressive nature of the application."

The truck's configuration makes a difference, as well. According to Miller, single drive axle vehicles require more traction capability from tires than tandem drive axle vehicles.

Another consideration is puncture resistance. "Tires with built-in sealants can greatly reduce vehicle downtime and the associated costs," says Miller.

Compound and casing trade-offs

According to Tolbert, rubber compounds play a significant role in protecting a tire from damage and enabling it to perform at a high level. They are formulated to address the specific needs of a range of different applications.

"Certain compounds are better suited for predominantly highway use," he explains. "Other compounds, whether in the tread or sidewall areas, are designed to resist chipping, chunking, cuts and punctures from debris in the harshest of off-road applications."

To maximize longevity, it's important to apply the right compound to the application. "Tires designed for highway use tend to chip and chunk when exposed to off-highway situations for long periods of time," Miller points out. "Conversely, a tread compound that resists chipping and chunking will not deliver long tread wear if used in an over-the-highway situation."

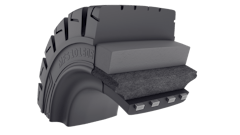

The design of the casing is also critical. "On/off-highway tire casings are built to be flexible and resilient, so the tire 'envelops' or wraps around an obstacle," notes Guy Walenga, director of engineering, Commercial Products and Technologies, Bridgestone Americas Tire Operations, LLC. "Flexible belt packages are built to use steel cables made with fewer twists and more space between the cables, while split-belt construction keeps the footprint flexible."

Surprisingly, the toughest part of a tire's job may not be on the work site, but on the road to and from it, he adds. "Flexible casings and tough tread compounds are built for long life on a rugged jobsite. That's one of the reasons why on/off-highway truck tires usually carry a lower maximum speed rating than on-highway tires," he explains. "If you need to travel Interstate-type roads to and from the work site, select tires with a 65-mph speed rating. Be mindful that some of the most severe-service tires are rated for 55 mph. Watch your speed to and from the jobsite."

The "black art" of tread design

There is actually a science behind the tread pattern on a tire.

"Tread patterns provide the necessary traction levels for the application or environment in which the tire is operating," says Tolbert. "The more time a vehicle will be spending off road, and the more severe conditions are, the more aggressive the tread design. Certain tread designs are also capable of ejecting stones that can become trapped in the sipes and can damage the tire if they work their way down to the belt area."

Soil conditions dictate the needed levels of traction. For instance, thick mud calls for an aggressive tread pattern. "Knobby lugs or chunky blocks bite into the mud for superior traction," says Walenga. "You will find lugs and blocks on drive radials. For all-position tires, look for aggressive shoulder designs for more grip."

However, bear in mind that the same tire may perform differently as conditions change. "Some tires tend to 'clean' themselves of mud/dirt with each rotation, and others seem to become slick as the grooves fill up," Miller comments. "There are as many different types of soil as there are tires, so a tire that may work well in one type of soil might work terribly in another. If this is an issue, you may need to test different tires/tread patterns to find what works best in your area."

Every tire has its intended application with associated benefits and drawbacks. "An all-position tire has a more rib-like tread design that typically wears longer than a lug/traction tire, but it doesn't have the biting traction required in some situations," Miller explains. "Conversely, a lug-type, deep traction tread will not wear very well on pavement."

You also have to balance traction needs against fuel economy. "Tires with more aggressive tread patterns are going to be less fuel efficient," Tolbert states. "And obviously, tires that are designed for more on-road use than off-road will typically get better fuel economy."

Maintenance pays for itself

Proper selection is only half of the tire cost equation."Even if the right tire is selected, it must also be properly maintained to maximize its life and performance," says Tolbert. "Tire pressure maintenance should be the centerpiece of any fleet's tire management program."

Proper tire pressure allows the tire to act as suspension, minimizing vehicle bounce as it encounters bumps in the haul road or work area. "This means that the energy is used to propel the equipment forward, rather than wasted bouncing the vehicle vertically," says Tolbert.

"Quite simply, it is the air that carries the load, not the tire," says Miller. "The tire is a container for the air and provides the traction required to keep a vehicle going in the desired direction.

"Tires are designed to carry a certain load at a particular pressure," he continues. "An error on the high side (slight over inflation) is more desirable than under inflation. Low inflation pressure leads to a tread wear mileage shortfall and a casing that may not result in as many retreads."

When tires are run under inflated, there is a greater chance for irregular wear on the outside of the tread area. "They can also experience excess sidewall flexing and, depending on the speeds being traveled, could lead to excessive heat buildup and a tire failure," says Tolbert. Excessive flexing also wastes energy, which reduces fuel economy.

Over inflation can lead to potential irregular wear, as well, this time toward the center of the tread, which tends to bulge slightly. "This smaller footprint is less efficient and can negatively impact traction levels," Tolbert points out. "Over-inflated tires are also more susceptible to chips, cuts and punctures from debris along the roadway."

Maintaining alignment is another element in reducing tire wear. "Proper wheel alignment is more important on an over-the-highway truck than an on/off-highway truck," says Miller. "But it is still important."

"Proper alignment will keep the tire's footprint in contact with the ground and help get the best performance out of the tires," says Tolbert. "Proper alignment will also help to prevent irregular wear that commonly takes tires out of service early."

Cut Costs with Retreads

"Retreading helps you gain the most value possible for the investment you've made in your tires," says Chris Hoffman, manager TBR and retread product marketing, Bridgestone Bandag Tire Solutions. "Simply stated, it helps lower your cost per mile or hour of operation.

"Depending upon the road and jobsite conditions, you can retread most types of on/off-road tire casings several times to capture [their] total value," he continues. "Also, retreading a tire casing costs on the average between 40% to 60% of the cost of replacing with a second or third new tire."

Tim Miller, Goodyear Tire & Rubber, estimates retreads cost approximately one third that of a new tire. He notes, "A well-maintained, quality casing can deliver three to five retreads, maybe more, depending on the type of service."

If you plan to retread, don't skimp on tire quality. "Because of the rigors of off-road applications, fleets should select high-quality tires, [since the] casing durability would be better able to withstand the retreading process," says Chris Tolbert, Michelin Americas Tires, "provided the tires are properly maintained throughout their first life."

He adds, "Even if properly maintained, some tires might not be retreadable due to excessive damages." So turn to a trusted retreader to inspect every casing and determine if it can withstand the retreading process.

Hoffman suggests that fleets ask their retread tire dealer to help them design a tire management program that includes an aggressive tire inflation best practice.

"Also, fleets should ask their tire dealer to recommend the right tire design for the conditions on the jobsite; the amount of traction needed and the speed rating for the roads traveled to the work site; and load rating for your vehicle type," he advises. "Not only will you want to carefully choose your tire designs to work effectively, it's also important that you don't pay for more tire than you need - particularly when it comes to load ratings."