For 2010, the U.S. Environmental Protection Agency (EPA) will require a reduction in nitrogen oxide (NOx) from diesel engine exhaust. All but one engine supplier for medium- and heavy-duty trucks have announced they will be using a technique known as Selective Catalytic Reduction (SCR). While this is a proven technology, it will be the first time it is implemented on heavy-duty trucks in North America.

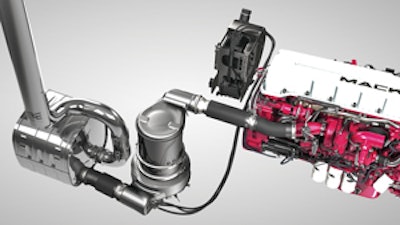

"The SCR system is in addition to the exhaust aftertreatment that is generally already in place - in our case, that would be the diesel particulate filter (DPF)," says David McKenna, director of powertrain marketing and sales, Mack Trucks. "The EGR valve and the EGR cooler remain the same, and the DPF remains essentially the same with some very minor updates and improvements."

Mack Trucks asserts SCR is a proven technology that delivers improved fuel economy and near-zero emissions. "It's already being successfully used around the world by hundreds of thousands of trucks every day, including those in extreme operating conditions," says Dennis Slagle, president and CEO. "And it clearly works here in North America, as our test trucks have been demonstrating."

David Siler, director of marketing, Detroit Diesel, adds, "SCR has absolutely proven to be reliable and cost efficient around the world. Nearly 100% of all vehicles meeting the latest Euro 5 standard are doing so with SCR. It has been around in the stationary power generation business since the 1980s, and has evolved into one of the most cost-effective emissions-reducing technologies that just so happens to deliver economic improvements."

Cummins also has significant experience with SCR. "In 2006, Cummins launched its midrange engines certified to the Euro 4 standard using SCR for commercial vehicle applications in Europe," notes Christy Nycz. "Cummins has built and shipped over 45,000 SCR engines to date. Cummins Emission Solutions has built and shipped over 200,000 SCR systems."

How SCR works

"SCR is an exhaust aftertreatment system that utilizes basic chemistry to reduce NOx to near-zero levels, while allowing the vehicle's engine to operate at optimal conditions to reduce stress and fuel consumption," Siler explains. "The chemical NOx reduction is the result of introducing very small doses of a non-toxic diesel exhaust fluid (DEF) into the vehicle's exhaust downstream, while not adversely affecting the engine's performance like has been generally accepted in emissions changes prior to 2010."

An SCR system consists of a few basic components: an SCR catalyst aftertreatment chamber, DEF tank, pump and lines, and control and monitoring system. DEF is injected into a catalytic converter. The DEF fluid is made up of water and urea. The urea turns to ammonia when heated. This reacts with the exhaust stream when passed over the catalyst, forming nitrogen and water vapor, both of which are harmless.

SCR may actually simplify the engine design. "SCR won't increase the need for complex and heavy air management and cooling systems as it appears extreme EGR systems will, nor will it degrade engine power density like extreme EGR systems have shown a tendency to do," says Siler. "However, SCR components will add between 100 and 400 lbs. to the chassis, depending upon application and the size of the DEF tank. Since most SCR systems have had years of development time to integrate with the leading chassis manufacturers, the impact on vocational packaging requirements are being minimized."

Exactly how much DEF will SCR-equipped trucks consume? According to estimates by McKenna regarding Mack Trucks, the system will dose at a rate of 3% of the fuel rate. "If you consume 100 gal. of fuel each day, you would consume approximately 3 gal. of DEF," he says.

Benefits of SCR

"By selectively eliminating the NOx downstream of the combustion chamber, the NOx produced by the engine can be much higher," says Ed Saxman, product manager - drivetrain, Volvo Trucks North America. "This allows the truck to be retuned for maximum fuel efficiency."

In fact, Cummins reports significant fuel savings during testing. "For our midrange engines, our testing indicates a 5% to 9% advantage relative to an in-cylinder solution," says Nycz. "Cummins heavy-duty products will deliver up to a 5% fuel economy improvement over our 2007 products, and our testing indicates that this improvement is even greater when compared to in-cylinder solutions."

There are other performance benefits, as well. "Cummins heavy-duty and midrange products will deliver the same power and torque as today's products without increasing displacement," says Nycz. "Throttle response will be improved relative to today's products. The engine has a larger 'sweet spot' for easier driveability, producing optimum fuel economy and performance."

Cummins also claims SCR is less complex than if the company had chosen to use an in-cylinder approach, which would require significant changes to the EGR system, air-handling system and vehicle cooling system.

Siler backs up these claims, noting, "The biggest benefits of SCR are that it is clearly more fuel efficient, is proven and reliable and meets or exceeds any known emissions standards in place for 2010 or beyond. The trade-offs are the addition of an SCR catalytic converter and the need for consumption of a secondary fluid.

"But it is Daimler's experience, as well as nearly the entire rest of the world's," he continues, "that the convenience and reliability of SCR, combined with its proven economic and emission-reducing advantages, build an almost insurmountable advantage over any other technology being considered to meet 2010 emission regulations."

The operating costs of SCR systems are also expected to be significantly lower than other alternatives being considered. "This has proven to be the experience of customers of all sizes or vocations around the world," Siler asserts.

Recent industry forums have placed the cost of a gal. of DEF at around $2.70, and Mack estimates only 2 or 3 gal. will be needed per every 100 gal. of diesel consumed.

However, the cost of the additional fluid will be more than offset by the savings in fuel economy. McKenna adds, "Mack Trucks is confident we will achieve a minimum 2% to 3% gain over our current engines - which are already achieving +3% in highway and +10% in Mack vocational applications vs. U.S. '04 - and at least the same over heavy-duty engines using non-SCR solutions for 2010, even if the latter operate above the .2 g NOx standard." (Note: .5 is the allowable maximum under the 2010 regs.)

Operating costs will actually decrease compared to the previous-generation trucks. For example, Saxman reports, "The total cost of fuel plus DEF for Volvo's EPA 2010 D13 engine will be 5% less than the acclaimed 2004 Volvo D12 engine under similar conditions."

But what happens if the system runs out of DEF? Let's look at a Mack truck as an example. "Each 2010 SCR chassis will be furnished with a clearly marked and ISO symbolled DEF tank gauge, which is in addition to the fuel gauge," says McKenna. "When the DEF level drops to a preset level, a small indicator lamp will illuminate the dash, indicating approximately 25% of DEF capacity remaining. At approximately 2.5% to 5%, there will be an audible tone now sounding, as well. When the DEF tank is completely empty, the engine will go into a power de-rate so as not to create high levels of NOx."

What about maintenance?

According to Saxman, "The SCR components will require minor maintenance, the same as any other components on a truck.

Siler adds, "The only scheduled maintenance that is new on SCR 2010 vehicles will be a low-priced, medium-efficiency DEF filter that can be replaced every 300,000 miles or so. The remaining maintenance items on 2010 vehicles will be the same or even less frequent than EPA 2007 vehicles."

Likewise, life expectancy is not expected to be much of an issue. "The SCR system is robust to say the least, with all double-wall stainless steel construction, stainless steel inlet and outlet piping with stainless hardware," says McKenna. "We are expecting something in excess of 22,000 engine hours or approximately 10 years [life expectancy]. There will be some variables that will positively or negatively affect this time, such as application, location and duty cycle.

"We expect the maintenance intervals to be the same as we have today, with a goal of increasing oil drain intervals," he continues. "With regard to the SCR system maintenance, an annual inspection of the pump and filter unit and DEF injector is expected. The filter is attached directly to the supply pump, the injector is located at the base of the DPF and both are readily serviceable."

SCR systems will come with a higher price tag. "Like with the introduction of any new emissions-related technology, the up-front costs will increase," says Siler. "But for the first time, SCR technology will deliver an economic and performance benefit that has not been available to customers before 2010."

And for more good news, don't expect many regulated changes after 2010. "There are no known plans from either Federal EPA or CARB that have been proposed," says McKenna. "Think about it. Particulate matter emissions are limited to 0.01 gram/brake hp and NOx emissions will be at 0.2 gram/brake hp. These are essentially near-zero amounts that we have a difficult time measuring accurately."