Return on Investment (ROI) has been on the tip of every company's tongue since the economy began its downward spiral. Whatever you purchase has to save you money or make you money in a calculated, measurable timeline or you don't buy it -- bottom line. Contractors fighting fierce competition, plummeting profits and increasing costs need all the help they can get.

At first glance, wireless fleet management can seem like a costly addition, and one that's difficult to justify. It's not a machine you can put to work or materials you can use on the jobsite. It's information for intelligent business decisions. It's how your machines are working on the jobsite. It's about increasing efficiency and cutting costs. And in this challenging economic climate you have to cut to increase profits.

This article focuses on how contractors can, have been and will, leverage wireless asset monitoring systems that deliver the real time data necessary for increased fleet efficiency and containment of operational costs.

Accurate data results in substantial savings

Contractors face an interesting conundrum: equipment usage (from hour meter readings) is used for job billing, service scheduling, budgeting equipment purchases and estimating work. However, almost every contractor I have worked with will quietly admit that this information is inaccurate and out of date. Inaccurate in that the information is manually collected in the field and subject to a variety of "mistakes" such as fudging, hoarding practices, timecards and other gamesmanship. Out of date in that at best this manually collected data is delivered 1-2 weeks behind real time. So how can a contractor efficiently bill, maintain equipment, make buying decisions and bid with such erroneous, stale data?

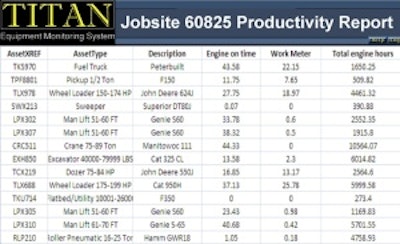

Right sizing your fleet, a fleet size decrease of 5%-10% while maintaining the same level of work. Running an analysis quarterly, monthly, annually or whenever your budgeting needs arise of utilization by asset type based on actual run time makes it easy to see where your fleet has an excess and where you may need to add a machine.

For example, if the contractor has 30 dozers in the fleet and requests are coming in for additional ones, a quick utilization report shows they have 15 dozers running at 80% utilization for the last quarter, 10 dozers at 50% utilization and 5 dozers at 20% utilization. The reality is that they don't need more dozers. In fact, they can shed a few to bring up the overall production of that asset class within their fleet -- which also frees up the capital they had tied up in non-productive machines. Just one round of "right sizing" and shipping underutilized assets off to auction delivered a yield of $900,000 in cash for this customer. Formerly, those high-value fixed assets were all sitting on their books and tying up capital and ownership costs, but with a few quick reports the fleet became streamlined.

Improved jobsite billing of 10-30%. Some wireless fleet monitoring systems will empower you to designate boundaries on their mapping software which you label as your jobsites. As assets move into those areas, they are assigned to the job and as they move elsewhere they are reassigned automatically without manual entry. This allows you to run jobsite reports to see how much your assets are actually working, which in turn creates accountability at the jobsite level. No longer can machines be hoarded on jobs, while a similar asset is rented on a project down the road. Now you simply reallocate the machines within your own fleet first, before looking to rent another machine. Additionally, the any usage “fudging” is brought to light and the job is billed properly for the actual work performed by the equipment.

Reduced equipment idling by 1/3 on average. The hour meter is one performance metric, but it doesn’t differentiate between “on time”, “working time” and “idling time”. Fortunately for you, a proper wireless monitoring system does. The obvious benefit: turning off the machine when it idles excessively, by implementing companywide idling goals and measuring them frequently.

Reducing the idle time will dramatically cut your fuel bill in the short term and also give you a realistic usage barometer for that machine. Now you will schedule service not off the hour meter on the machine, but the true “working time” meter on the hardware unit – which means you will reduce the number of PMs required annually.

Consider a service interval at 250 hours and a machine with 30% idle time, equating to 75 hours of idling per service. This means that every fourth PM is due to the idling hours alone, which is not a true indicator of usage. As you reduce your idling or simply schedule service off the actual “working” meter, you extend the PM interval and decrease the number required. Taking the example above, if you ran your service strictly off the true “working” meter then you would completely remove every fourth PM - and its associated costs.

Reduced service and repair costs of 15-40%: Using a wireless monitoring system provides a proactive service scheduling function (a report showing what is coming due) as well as a reminder if an asset is not serviced on time, thus preventing any from falling through the cracks. The result is fewer failures and thus less repair costs and equipment downtime.

Insurance savings of 20%-60%. Most wireless asset monitoring systems also double as theft protection systems with such features as nightly curfews, real time theft alerts, immobilization techniques, remote disable, geofences, etc. Ask your insurer what break they will give you for theft protection. If they can’t justify it, then be sure to remind them that there is at least one underwriter out there offering at least 25% discounts on premium and a $10,000 theft deductible to contractors who invest in this technology

More bids, profitably. Armed with the real utilization information from previous jobs, your estimators will now map that to future bids. Rather than estimating, they are using actual numbers from identical work to make their bids more competitive and profitable.

Too good to be true? Consider the case of a customer coming up on their one-year anniversary with our technology, having installed nearly 500 units on their equipment fleet. That investment has yielded a savings in excess of $3 million within 10 months from the exact same items discussed above, exponentially outweighing the cost to deploy. The investment today has paid for itself in the short term, and they are poised to be even more efficient and competitive as the economy turns around.

Tony Nicoletti is the Director of Sales for DPL America, a leading provider of GPS-based asset tracking solutions. You can contact Tony directly via phone 650-965-1636 or [email protected], and more information is available at www.dplamerica.com.

_________________

Customer Profile: Highway, Bridge and Road Contractor

Following is a case study of an actual customer using a DPL America wireless asset monitoring system:

-Fleet size of $100 million

-750 units installed (not entire fleet $100 million)

Fleet productivity increase

Automated reporting to monitor actual use, combat hoarding

- Fleet size reduction by 3%, $1.2 million in capital freed

- Captured $70,000 unreported rental from jobs

Theft Protection

Six layers of protection: curfew, remote disable, etc.

- Insurance premium decrease of $300,000 annually

- Prevented loader theft ($130,000), recovered mechanic truck and welder (100,000), and new backhoe ($80,000)

Idle Time Reduction

Reduced average equipment idle time by 1/3 via automated reports

- $1,106/year average savings on wheel loaders and backhoes

- $603/year average savings on grader, dozer and rollers

- Extended average equipment life by 1.2 years

Still to come…

Using actual jobsite data for future estimating, increasing service efficiency

- More competitive, profitable bidding, revenue gain TBD

- Service and repair cost reductions, TBD

![Dpl Logos Final Primary Horiz 2[1]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2024/09/DPL_logos_final_primary_horiz_2_1_.66db1de0a84c3.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=167&q=70&rect=108%2C397%2C1885%2C1057&w=250)