To be successful contractors not only have to identify niches where they can provide a service, they also have to make themselves stand out within that service niche. Gloria Jeane Hauling and Highway Rehab Inc., Arlington, WA, has done both.

Beginning as a start-up oil hauling operation in 1991, Gloria Jeane Hauling, named after founder Gloria Tonsgard, added pavement milling to its services in the mid-1990s to capitalize on an ever-growing need for road rehabilitation and other infrastructure improvements.

But Gloria Tonsgard didn't want to run just another milling operation. She wanted to differentiate her company from the competition by providing a service they didn't provide. So she guaranteed pavement cleanup after all milling.

"We're known in our market for doing all the cleanup. That's what my Mom wanted when she started doing grinding," says Loren Tonsgard, general manager. "We started guaranteeing people the jobsite would be asphalt ready."

And Gloria Jeane has not only made itself stand out in the Washington market, it has raised the level of milling in the area because other contractors now offer cleanup also.

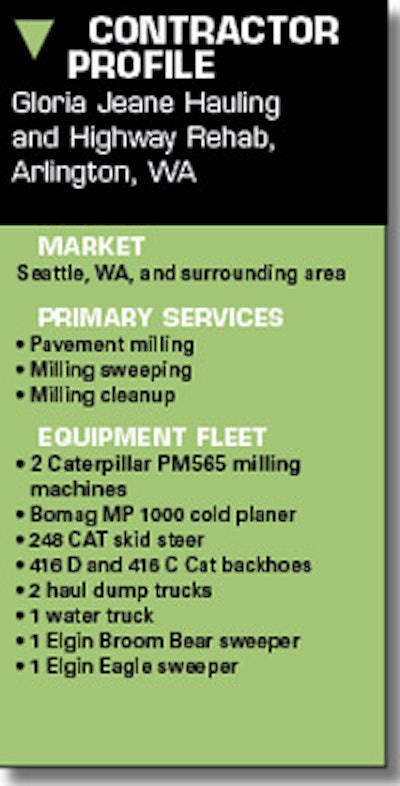

Gloria Jeane's current fleet includes two large Caterpillar PM 565 grinders and a Bomag MP 1000 cold planer. The contractor employs as many as 25 people during the peak summer season, running three crews full time. Crews include an operator, a grounds person, a truck spotter, one or two jackhammer operators, a backhoe operator, and a skid steer operator. Tonsgard says 90% of their milling work is on roads, with 10% on parking lots.

With all three machines operating Gloria Jeane Hauling handles between 20 and 30 milling jobs a week, or more than 1,000 jobs a year. Most of the company's jobs are bid-and-contract work, though the jobs with the 3-hour minimum are often done "with a phone call and a handshake."

Tonsgard says the long-term result is often repeat business from a number of small paving companies in the greater Seattle area.

"Several companies use us exclusively for any milling they need done," Tonsgard says. "Often they'll have multiple jobs for us in a week, even as many as three per day during our peak season. So we keep our milling machines busy."

Cleanup eases paver's job

Tonsgard says that while many milling contractors run crews of only two people, Gloria Jeane runs larger crews because of the service it guarantees its customers. He says cleanup, which includes sweeping, takes more work and requires more labor, but Gloria Jeane's incorporates that into its rate.

"We bid it and we get paid to do it," Tonsgard says. "It's a service we offer that almost all our clients take advantage of."

He says most milling operations stay an inch or more away from the edge of any concrete and that inch of pavement must be removed before any paving can take place. Milling machines also steer clear of obstacles such as manholes and catch basins, so the pavement surrounding those obstacles also must removed.

"Cleanup is key, it's important and says a lot about the quality of work we do," Tonsgard says. "We leave and all the paver has to worry about is paving. They don't have to worry about wedges, they don't have to worry about the edges, and they don't have to worry about pavement left behind around any obstacles."

He says that because of the cleanup work Gloria Jeane's crews do, the paving contractor has a much simpler job ahead of him. The paver, for example, can bring a smaller crew because much of the labor-intensive work is already done. Plus, the paver doesn't have to haul out equipment such as a compressor, jackhammer, skid steer, or backhoe to the site.

"They just bring their paver and he's ready to go. It's stress free for them and they can just get down to paving and that really helps the job go faster and helps keep their paving operation productive," Tonsgard says.

A recent job on Milton Mall Center, Milton, WA, was a subcontracting job for Benjamin Asphalt, which hires Gloria Jeane Hauling to perform milling regularly. The Milton Mall job was a large-scale patching operation that required milling to up to 6 in. deep of a number of large patches, some as big as 20 ft. x 30 ft. Gloria Jeane was on the job for parts of three days, milling and cleaning up the pavement so Benjamin Asphalt could come in and pave the patches.

Utility milling

Another recent project was an uphill milling job in Somerset, WA, on a subcontracting job for Potelco Inc., a provider of power line construction, natural gas distribution, and fiber optics. While multiple construction companies are typically called upon to handle the installation of such services, Potelco specializes in laying the entire gamut of utilities - from gas to electrical to telecommunications - in creating what the company dubs "unity trenches."

Gloria Jeane's involvement with Potelco illustrates how milling subcontractors today are experiencing business growth not only because of failing roadways and streets, but also because of the need for improvements to the aging infrastructure of cities across the country. Because Potelco's work almost always involves tearing up existing asphalt to create unity trenches, Gloria Jeane has gotten a lot of work.

"They use a trencher to dig down about two or three feet deep and a foot wide," said Jones. "Usually they're putting in the fiber optics and other utilities all week, and then we go in when they're finished. How it works is that we'll straddle their trench with our milling machine and take the surface down about 7 or 8 inches. That way they can get a paver in there to pave it back. Including milling and loading, we typically grind 1,500 feet for them within 3 hours."