In some circumstances, it would have been a generational clash with a less than positive outcome. Instead, it became a deliberate decision that will help preserve a family business for years to come.

Frank Carroll, the founder of the company that bears his name, had built a successful business from scratch. He had done so slowly and steadily, so he needed some convincing when his son, Frank Carroll II, said it was time to buy a new plant.

"We're a small business, we don't have the deep pockets that some do," says Frank II. "We had to strategically plan."

The Carrolls - including another son, Michael - addressed the issue. It took some discussion, but Frank Sr. was persuaded.

Ultimately, he also realized the company was at a crossroads. Its asphalt laydown business had grown substantially, meaning outside customers were having mix supply problems.

More urgent was the situation with company crews, which were putting in longer days because of the existing plant's limited capacity.

"My father would tell me I had to go home and not work all day, and that the crew should go home too," Frank II says. "I would tell him that wasn't efficient."

In many instances, the crew would be in the middle of a job that only needed another 100 tons or so to complete the work. "I wasn't going to knock off and then go back the next day and lay 100 tons," Frank II says. So the work continued, late, until the job was done.

Eventually, all three Carrolls agreed to investigate the purchase of a new asphalt plant. They evaluated and settled on equipment in the same deliberate fashion in which they conduct all their business. "We take our time and do it right," Frank II says.

Growth increases demand

The discussion began in the late 1990s. The asphalt division of the company had started in 1986, shortly after Frank II arrived at the business. The division originally supplied materials to outside customers, but that changed with an acquisition that gave the firm a paving crew.

"We had a two-ton plant," Frank II says. "It was fine before we had the crew. But the crew was successful, and we started getting more and more business — and started doing DOT work, which required a lot of Superpave. Changing mixes became more of an issue, and we ended up hogging our own plant."

By 1999, the laydown business had grown by 50 percent.

"We still had a two-ton plant," Frank II says. That's when the Carrolls started to discuss expanding.

The decision

The Carrolls agreed there were some advantages to expanding. A larger plant could more quickly provide material for the crews and reduce the length of the work days.

"My father realized I probably wasn't going to change my ways," Frank II says. "I wasn't going to start carrying 100 tons over to the following day. It didn't make sense."

The way to limit the crew's hours was to deliver more asphalt during the course of the day. This would keep the paver moving more steadily and end the work day sooner.

There were other advantages to an expansion. Finishing jobs more quickly also meant a productivity boost for the crews. In addition, the Carrolls felt confident they could sell more mix if they could produce it.

"We all could see the need," Frank II says. "It was just a matter of us being a small company. But we asked ourselves, ‘Where are we heading, and what are we going to do?'"

They decided to explore a purchase. They looked at a new plant, but also evaluated what other areas of the business would be affected.

"Internally, we had to restructure crushing so we could feed aggregate to a bigger plant," Frank II says. "That took about three years."

Next, the firm took a break financially, and built up cash for another three years. Meanwhile, they thoroughly examined their plant purchasing options. They found some manufacturers were more interested in pushing products rather than helping the Carrolls find the right equipment.

Sticking with a batch plant

"We wanted a batch plant," Frank II says. "We change mixes a lot. It's not uncommon to have two crews out there and run four or five mixes a day."

The company and its employees also were comfortable with a batch plant - and it showed. "We were very successful with our early batch plant," Frank II says. "Our paving crews regularly earned bonus pay for hitting specs, and that starts with quality mix."

Other companies repeatedly tried to push a drum plant. The Carrolls listened to the sales pitches for a while, but eventually grew weary of trying to convince a sales rep that a batch plant was the way to go.

"Gencor never did that," Frank II says. "They understand the business enough to know that there are times when a batch plant is the best fit, and they sold us one."

The knowledge didn't end with the sale. Gencor found a way to make the larger plant (4 tons) fit on the existing footprint.

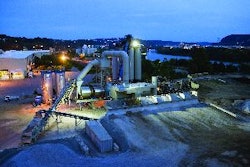

The plant went online in June 2007 about eight years after the discussions began. "The transition was very good," Frank II says. "Gencor provided four really good installation specialists with outstanding knowledge and a great work ethic. They got us up and running."

An unqualified success

"It's working well," Frank II says. "We love it. It's given us the production we're looking for and shortened our days. Before we weren't getting asphalt to the jobsites fast enough. Now we are. Instead of producing 1,200 tons a day, you can deliver 1,800 tons to the crew — in about the same time."

Just as important, F.R. Carroll Inc. is once again meeting the needs of its outside customers. "We lost some business because we couldn't supply them," Frank II says. "Now we have them back."

The increased crew productivity, combined with the outside sales, is making the investment pay off quickly.

Not too many years ago, the Carrolls were debating whether to expand. Their internal discussions now don't include a debate over whether they made the right move — all agree they did. "My father will tell you it's the best thing we ever did," Frank II says.

The Gencor batch plant F.R.Carroll Inc. began operating in June 2007 offers many benefits. Among them:

- Better built - Improvements in engineering, including a new style baghouse features counterflow cleaning air that gives the plant more air to run.

- Fuel efficiency - At least 20 percent more fuel efficient than the Carrolls' old burner.

- Reduced emission - Lower emissions make for a good business neighbor.

- Downtime avoided - Losing a few hours versus a few days a year to unscheduled downtime is the name of the game.

- Quiet - An insulated dryer shell prevents heat loss and reduces noise; since the baghouse doesn't use compressed air to clean the bags, there is no sound of air blasting.

- Proper training - After running the plant for a year, training opportunities helped operating crews identify the information they needed to maximize the plant's performance.