Just a few years ago, Rod Vilhauer and Barry Rich, owners of Rodman Companies based in Frisco, TX, had nothing to smile about when it came to tire acquisition and service costs. As one of the company's highest transportation expenses, these costs were a moving target.

Today, things have changed. After implementing a new tire program developed by Goodyear and its service subsidiary, Wingfoot Commercial Tire, Rodman has erased $152,000 off its balance sheet.

Rodman Companies operates an on-road fleet of about 120 medium- and heavy-duty trucks and 100 trailers, hauling permitted loads from 84,000 to 300,000 lbs. on trips up to 600 miles. According to Shawn Schneider, manager of process improvement, as of November 2007, it had saved 26% on its cost per-mile for the transportation fleet vs. November 2006. With transportation costs that fluctuate month to month, Schneider expects the cost per-mile for 2007 to come in at 40% less compared to 2006.

Tire costs were reduced by, among other things, using new Goodyear tires and retreads when possible; getting more miles from a new set of tires before removal via routine inspections, pressure checks and air-ups; and increasing retreadability by identifying conditions under which tires would be pulled for retreading.

The means for cost control

Rodman Companies builds subdivisions, malls, golf courses and other building projects, mostly in urban areas. Because it operates excavation, utilities, paving, landscaping and power and communications divisions, it is a turnkey operation that often does all work associated with a construction project. That's why it operates a large, diversely equipped truck and trailer fleet and about 900 pieces of other heavy equipment.

With different operating divisions, tire-related decisions were not centralized at Rodman, Schneider notes. The company didn't have a written program for management and vendors to follow. Consequently, decisions such as what size and type of tires to buy, when to remove them for retreading and how to maintain them were made on a case by case basis. Instead of anticipating needs, company employees and their managers reacted to the circumstances at hand.

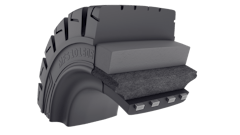

John MacMullin, Wingfoot Commercial Tire regional director, collaborated with Schneider on a proposal that promised to reign in the runaway tire costs. It called for Wingfoot to handle the company's entire tire inventory. Rodman wouldn't need to keep any tires on hand in its maintenance facilities, enabling it to potentially save a lot of money in handling costs and taxes. In exchange, Rodman would entrust Wingfoot Commercial Tire with all of its tire and service needs, buy all Goodyear tires and make use of the NEXTRED (precure retread) process.

Vilhauer and Rich approved Schneider's and MacMullin's proposal and gave them a year to get results. Rodman's equipment and aggregate haul trucks now use the Goodyear G395 LHS tires on the steer positions. Tandem dump trucks run the G149 RSA tire. The company also uses the G287A in size 315/80 R22.5 and the G286A Super Tough Single in size 385/65 R22.5. By choosing the right tire products for the applications, Wingfoot significantly increased the mileage and retreadability of Rodman's tires.

Despite adding more trucks and trailers to its fleet this year, and running nearly 1 1/2 million more miles by the end of November 2007, Schneider still expected Rodman's savings in tire service and acquisition costs for the transportation fleet to be in excess of $200,000 at the end of the year. He admits the operational changes necessary to get that result were far from easy.

Proactive approach

Urban environments are ruthless on truck tires. Debris on the roadways and on construction sites can wreak havoc on tire casings. Plus, the turning and twisting that happens as drivers maneuver into and out of jobsites can lead to sidewall scrubbing and other issues. "You almost can't keep enough tires and casings on hand," Schneider says.

Before the new tire program was implemented, Schneider and MacMullin established the company's performance goals and tire specifications. Rodman and Wingfoot employees now take more proactive measures with tires to ensure these goals and specs are met.

When Rodman employees routinely inspect and replace tires, they also air them up, making sure the pressure readings match between duals. Wingfoot service technicians also inspect and evaluate tires quarterly, entering their inspection results into Goodyear's Tire Vehicle Tracking System or TV TRACKS. They compare these results with the specs Goodyear established for Rodman to determine if the tires should be removed and retreaded.

"MacMullin and I then sit down on a biweekly basis, look at the TV TRACKS reports and determine where we are and where we want to be," Schneider states.

Ordinarily, fleets would be reluctant to share such information for fear of providing its vendor with reasons to raise prices, says Schneider. But instead of holding that information close to his vest, he works with MacMullin to determine targets for overall fleet costs on both the transportation and excavating side that are standard for the construction environment.

"We track exactly how many miles I run on my trucks, how many hours I run on my excavation equipment and how many service dollars and tire dollars I spend," says Schneider. "I collaborate with Goodyear and Wingfoot to find out how to save money. We consider questions like, 'Should we pull tires earlier? Do we have enough retreads?'

"It's more of a partnership," he adds.