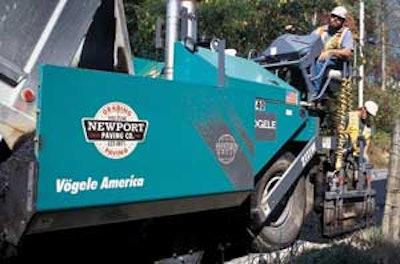

The smallest paver from Vögele America Inc. — an 8-foot 2111W rubber-tired paver with HF400D screed — is doing a giant job for contractor Newport Paving & Ready Mix Inc. on narrow county roads in the Tennessee foothills of the Great Smoky Mountains.

The maneuverability of the small paver on tight, uneven mountain roads — combined with the roadability provided by its rubber tires and front-wheel assist drive — made it the right choice for Newport.

"We use it for state-aid paving for counties, in which the state supplements the counties each year for paving certain roads, regular county paving, and city paving, state contracts and building sites," says Joe Malone, Newport general manager.

Newport acquired the Vögele 2111W based on prior experience by its owner, Charles Blalock & Sons Inc. Blalock employs over 500 in east Tennessee. Blalock specializes in heavy and highway construction, site work earthmoving, water and sewer installation, drainage construction, paving and base construction.

Malone says, "I love this paver. It's given us no problems, and that's important when you're a small company like us, because breakdown time kills us. If the equipment fails, it becomes much more expensive for me because we do a lot of work up in the mountains, and the downtime can be too much. Plus, it was very affordable for us."

Newport paves hot mix asphalt and manufactures concrete as well. The firm has two asphalt plants, two ready mixed concrete plants, and an aggregate crushing plant. The firm began as a small paving contractor in Newport 31 years ago, with three trucks and a paver. Today Newport has three pavers — including a Champion, predecessor to Vögele America — and operates two crews.

Traction on steep grades

Especially important is the front-wheel assist drive that the Vögele America 2111W provides. "We pave so much on steep grades in the mountains," Malone says. "We have to have something with a lot of power with good grip that can push the truck up the steep grades. Often we work grades as steep as 14 to 15 percent, and there are some subdivisions back up in the mountains with driveways that are 16 to 17 percent grade. In those instances, on gravel, we will come down the hill; we back the trucks up, fill the hopper, and come down the hill as far as we can, then back the truck up again. On existing asphalt we can pave upward. But most of the time we're in the 11 to 12 percent range."

Other pavers offer front-wheel assist, but it's not the same, Malone says. "We haven't found anything that works as well," he says. "Tracked pavers won't work for us because we 'road' the paver so often on these county roads that sitting on rubber tires is more efficient for us than tracked machines. We may have a county road that's a half-mile apart from the next one we're doing. If it's a tracked machine you have to pick it up and haul it. But if it's on wheels, we just 'road' it. It's quicker and more versatile; I can have it on the next job by the time I load it." The same applies to driveways; when Newport paves driveways with the 2111W they're often in 'roading' distance of each other.

When visited in October, Newport was using the 8-foot 2111W to place C-mix on Hartford Road in Cocke County, TN. "It contains 1/8- to 1/4-inch stone, a mix the county uses on its rural roads," Malone says. "The aggregate is coarser than a straight topping and gives traffic a little more support over roads that are broken up but not patched. It's what some people used to call 'baby binder', in-between a binder mix and a topping. We give them a good mix that will serve their local traffic and school buses, but try to keep the pricing down."

The 'goingest' machine ever

Newport's paving foreman — a veteran of 39 years of paving — is keen on the machine.

"I like its pulling power, it's the 'goingest' machine I've ever seen," says Doran "Gube" Huskey, paving foreman. "For its size — now pull, now push — to this day, as long as we've had it, there's never been a chain or cable hooked to it. I've never been stuck with it yet, and we've been in some soft places."

The small size of the paver works for Huskey. "It has the weight on the wheels so it has more pulling power," Huskey says. "I like the way the extensions work, and the hydraulics. I've been to three different dealers, tried them all out, and I liked this machine better. Plus, I've seen how Blalock's machine operates."

Newport's HF400D diesel-heated screed paves up to 14.5 feet with built-in screed extensions. Huskey says the action of the 2111W's augers is especially useful. "The augers will pick up, or raise when you get hung up or stuck," he says. "You can raise them up and that puts more weight on the rear wheels, giving you more traction. The action also helps by keeping the proper head of material. In my opinion it's the best machine for its size. I love that machine."