Tires were a tough commodity to get hold of throughout much of 2005. While tire manufacturers anticipate an improved supply/demand balance for 2006, it still makes sense to pay close attention to tire selection and maintenance for increased longevity. It can reduce tire costs and unexpected downtime, while maximizing the number of retreads and minimizing “crisis” purchases at your local tire dealer.

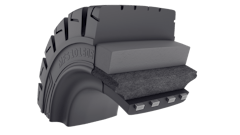

Tire selection for medium- and heavy-duty trucks has admittedly become a bit more complex in recent years with the introduction of more application-specific designs. That trend, according to Guy Walenga, engineering manager for North American commercial tires at Bridgestone, will continue. Gone are the days of the “one-tire-fits-all” methodology. Manufacturers now offer a variety of tire designs for on-highway, off-highway and varying combinations of both.

“That complexity is actually an advantage for fleets and owner/operators,” Walenga says. “Today, tread designs and compounds are developed for optimum performance in specific environments.”

Match to the application

To determine the best tire for your particular situation, tire manufacturers suggest you begin by estimating how much time you spend on and off the road. Your answer will help determine the correct tread depth and tread compound. “It’s a balance between traction needs, tread voids and mileage,” says Curtis Decker, national manager at Continental. “Misapplication tends to show up faster off-road because it’s a tougher application from the standpoint of expected mileage, heavy loads and impacts and abuse from foreign objects.”

But be careful not to overestimate the amount of traction you really require. “It’s easy to misjudge your traction needs,” Decker cautions. “Some people mistakenly believe that if they go off-road at any time, they need the most aggressive tire available. But if you have an off-road tire that spends a significant amount of time on improved surfaces, you won’t be satisfied with the mileage from your tires because you’ll burn them up on the highway. Purchase a tire that will offer the best option in the majority of the time that the truck is used.”

Additional aspects you will want to evaluate include off-road surface conditions, weight of loads carried and speed traveled.

“If you’re on gravel and rocks, you’ll want something different than if you run in soft soils or mud,” says Doug Jones, customer engineering support manager for North American tires at Michelin. “And if you go through a lot of debris, you’ll want a tire with reinforced sidewalls to resist punctures.”

Ply rating (along with air pressure) affects how much load your tires can carry. A heavily loaded vehicle will need a tire with a higher ply rating that will allow it to better handle the weight.

Many off-road tires have speed restrictions, some as low as 50 mph. As you move to line-haul tires, speeds increase. “If you don’t fully understand your application and mount the wrong tire, it will heat up and deteriorate, which will cause it to come out of service early,” says Jones.

Remember that your local tire dealer can be your best friend when it comes to matching tires to applications. “There are lot of different tread designs, compounds and sizes. So it’s best to work with your tire professional who understands all the options and knows how new tire offerings and retreads fit into your fleet,” says Al Cohn, technical marketing manager for commercial tires at Goodyear.

Protect your investment

Once you’ve spent the time and money to select the right tires for your application, you’ll want to focus on maintaining those tires to get the longest life possible.

“Every fleet needs to have a tire maintenance program. That program needs to be written down, well-communicated and followed,” says Jones. “Even if you outsource your maintenance to your local tire dealer, don’t take a hands-off approach. You need to make sure your dealer is doing it properly. By having a good tire maintenance program, you can minimize road calls and downtime associated with tire failures. You can also save money by using the casings multiple times rather than destroying them in their first lives.”

Regardless of tire brand or position, or fleet size, monitoring air pressure needs to be at the top of anyone’s maintenance list.

“Air pressure is so critical,” says Decker. “As tire manufacturers, we may sound like broken records, or that we don’t know what else to say. But at the end of the day, air pressure has the greatest impact on how long a tire will last — not only through the first life, but every life after that.”

Air pressure needs to be checked on a regular basis, ideally at the beginning of each work day when the tires are cold. Use a calibrated tire gauge to get an accurate reading.

The consequences of running on under-inflated tires can be costly in terms of irregular wear that shortens tire life, adds to tire costs and causes outright tire failures. “Running 20% under inflated costs you 16% in removal miles,” says Cohn, explaining that you’ll get 16% fewer miles.

Those lost miles are due in large part to the extra heat generated in an under-inflated tire. It flexes more than it’s designed to, creating excessive heat which breaks down the bond between the rubber and the steel. If severe enough, it can ultimately break open the air chamber. It also adversely affects your ability to retread the casing.

Consider an 11R22.5 tire, suggests Walenga. “Every cable in that tire will flex from rest to deflection, then rest again more than 500 times for every mile,” he says. “At 60 mph on the highway, you can see how that excessive deflection can destroy a tire. Heat is definitely the enemy. Proper air pressure for the load keeps the tire performing within the design parameters and keeps heat at bay.”

An under-inflated tire running as a dual can also wreak havoc on wear. Even with an inflation difference of just 5 psi, the distance a tire travels in one circumference (defined as rolling circumference) will vary by as much as 5/16th of an inch. When those tires are bolted together in a dual position, the two tires traveling at different rolling circumferences will cause uneven wear. “The tire with the larger circumference will roll along and the tire with the shorter circumference will have to skip to keep up, because with every revolution, it’s falling behind,” says Decker.

“It might not destroy the tire,” adds Walenga. “But it will certainly use it up faster. And it can, over a period of time, degrade the casing so you don’t get as many retreads as you could if air pressure was properly maintained.”

That irregular wear can also add to tire costs indirectly, notes Decker. “Every time someone touches a tire, it adds to the cost,” he says. “When a tire has to be rotated around the truck to give you the best tire wear, every time you take that tire off the truck, your labor costs go up.”

With all the dire consequences of running under inflated, you might be tempted to over inflate the tires to compensate for any air leakage. “But don’t simply pump air into the tire,” says Decker. “Find the inflation pressure that works for your needs and stay as close to that inflation pressure as possible. A comprehensive tire program centered around inflation saves money in the long run. That’s true for an owner/operator who may have one truck or a fleet with a hundred.”

Catch injuries early

Other maintenance items to add to your checklist include routine checks for debris. “It’s important to keep the tires clean,” says Jones. “Debris can get caught in the tread and sidewall of the tire and can cause it to deteriorate. Pay special attention to duals. Debris and rocks can get lodged between the tires and cause them to fail.”

“It’s natural in an off-road environment to pick up nails, screws, etc.,” adds Decker. “But the earlier you can catch an injury, the more successful the repair will be.”

You should also regularly reinforce to your drivers and mechanics the value of your investment, advises Cohn. Relate to them the costs associated with purchasing tires and the importance of taking proper care of that investment to reduce costs. “Encourage them to do regular walk-arounds before heading out for the day,” he says, “and remind them to not only check inflation pressures, but also check for uneven tread wear.”

Also develop and implement a rim program that includes inspections and maintenance. Some items to watch for include rim flange wear, elongated bolt holes and cracks.

A good way to check your tire selection and maintenance programs is to conduct a scrap pile analysis. “Look at every tire that comes out of service to get an idea of why tires are in the pile,” notes Jones. “It will give you a good idea as to whether or not you’re spec’ing the right tires and maintaining them for the longest life.”

“Make sure the reason tires are dying is because they’re used up, not because they’re abused or poorly maintained,” Walenga stresses. “You want to make sure that every tire that makes it to the scrap pile got there honestly. Use your scrap pile as a tool to help identify when to pull tires from service, to pick a new type of tire and to confirm the performance you think you’re getting.”

“It really makes sense to pay attention to tire selection and maintenance,” adds Cohn. “Other than fuel costs, tires are the highest maintenance cost a fleet will have.”