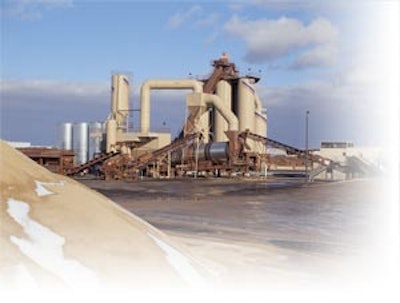

When it comes to meeting the hot mix asphalt needs of smaller paving contractors while still delivering large loads to major projects during peak days, bigger is definitely better, according to Todd Laubis, director of operations for Commercial Asphalt Co. of Minneapolis. With 10 plants in the twin cities area, some of them among the largest plants in the world, Commercial Asphalt, a subsidiary of Tiller Corp., is about as big as they come.

“We have a Gencor Ultraplant rated at 700 tons per hour, with seven silos and 14 cold feeds, that has produced over 800 tons of mix per hour,” says Laubis. “On peak days we have produced over 9,000 tons during a 14-hour period. We also have four 600-ton plants, a 500-ton plant, all from Gencor Industries. Accordingly, when we get a big job with a contractor that needs 3,000 to 4,000 tons a day from one of our plants, we can still meet our smaller contractors’ daily needs of several thousand tons from the same plant. And having 10 plants spaced about 15 miles apart throughout the metro area gives us another competitive edge by enabling us to bid out of a nearby plant.”

Pioneers in Minnesota’s interstate highway system

Commercial Asphalt’s predecessor was Barton Contracting Co., a road construction company founded by Gene Barton in 1946 when Minnesota’s interstate highway system was first being developed. For more than 20 years, Barton worked in all phases of highway construction including grading, concrete and bituminous paving, curb and gutter manufacturing, and sewer and water installation. When highway construction activities began to subside in the late 1960s, Barton shifted its operations from construction to materials supplier.

Tiller Corp., a privately held 250-employee enterprise, was founded in 1981 to act as a holding company for its subsidiaries, including Commercial Asphalt. These divisions currently employ 250 personnel and occupy approximately 3,000 acres of land in the Minneapolis-St. Paul metropolitan area for the purpose of aggregate mining, hot mix asphalt production, and asphalt cement storage and distribution. Hot mix asphalt is supplied by the company to residential, commercial and highway markets through the MN/DOT certified plant program. Commercial Asphalt Co. is one of the largest hot mix asphalt supply-only companies in the country.

Competitive challenges

As a materials-only supplier, Commercial Asphalt doesn’t lay hot mix, but still has to be the lowest cost producer.

“This requires that we be very competitive with other companies that have their own plants,” explains Laubis. “We have to be able to produce a variety of mixes, on demand, and for less, in order to be successful. Gencor’s versatile and high-capacity Ultraplant’s has enabled us to do that.”

In addition, with their numerous sand and gravel sites and the storage capacity to hold up to 30 million gallons of asphalt, Commercial Asphalt can buy materials during the off-season when rates are lower, a further competitive edge. Commercial Asphalt also has 10 crushing plants.

These competitive advantages add up to a three million ton annual output involving projects that range in size from golf cart paths to a five-year, 27-bridge interchange project over the Mississippi River. Although 80,000-ton freeway projects are typically considered large jobs, Commercial Asphalt’s large capacity Gencor Ultraplant’s handle these assignments with ease. “Our market niche is really quite large,” says Laubis.“We supply up to 250 paving contractors over the entire metro area in addition to the big highway projects.”

Choosing an industry leader

To produce up to three million tons of mix annually, size also matters when it comes to selecting a vendor to provide the necessary state-of-the-art plants, silos and other equipment. This led Commercial Asphalt to select Gencor, whose family of companies have pioneered many major advancements in asphalt plant technology over the past 100 years. “Gencor is an industry leader and produces the largest plants in the world,” explains Laubis. “But more importantly, the iron used in their plants is stronger and beefier, thus requiring less maintenance and assuring exceptional reliability. Gencor plants typically run above stated capacities as well ... the 700-ton plant averages 750 tons per hour, and the 600-ton Red Rock plant averages 680 tons per hour.”

”Gencor Ultraplant’s are also quieter and more environmentally friendly, which makes the permitting process a lot easier,” says Laubis. “We recognize that we have a unique responsibility to the environment and the communities in which we operate,” says Tiller Company President Gary Sauer. “In many ways, our use of the land may be considered an interim land use. As such, our activities must appreciate and contemplate the ultimate land use.” As a result of this commitment to Gencor and the environment, Commercial Asphalt has won many environmental awards over the years.

Mixing it up

Commercial Asphalt operates five to seven Gencor silos at each location enabling them to have several types of mixes ready to serve the any requirement at a moments notice. Minnesota’s HMA specifications typically include a variety of recipes pertaining to materials, mixture design, construction requirements, quality control, pavement density, thickness and smoothness. As a material supplier, Commercial Asphalt’s focus is on mixture composition and constructability. “Gencor’s Ultraplant mix versatility gives us another edge when it comes to serving our customers,” says Laubis. “These mixes include the popular Superpaves as well as the ultra-fine nova-chip overlays that reduce road noise.”

No matter what the requirement, Gencor’s Ultraplant can handle a diversity of mix designs without any equipment modifications or flighting changes.

Down the road

“It’s too early to tell what effect the new SAFTEA-LU highway bill will have on our business down the road,” says Laubis. “Although none of the work has trickled down yet, we expect that it will lead to continued growth and great opportunities in the metro area.”

Meanwhile, the new 600-ton large-capacity Gencor plant will replace an older, noisier plant in a residential area, thus continuing Commercial Asphalt’s legacy as a good neighbor and an industry leader.

In so many ways, size matters in the hot mix asphalt business.