Walk-behind saws are versatile machines in any pavement maintenance fleet. Keeping them in top working condition will benefit your bottom line.

Basic maintenance

Whether you're cutting asphalt or concrete, your daily maintenance schedule won't change a lot. Adjustments to the schedule come when cutting either wet or dry. You should always follow the maintenance suggestions found in the operator's manual provided by your saw manufacturer and the suggestions given in the owner's manual that accompanies your saw's engine, but following are some basic maintenance tips you should keep in mind every day.

1. Visual inspection. Before each operation, walk around your saw to visually inspect it for any problems. If you can catch a bent arbor shaft or a loose blade before starting up the machine, you can prevent damage and decrease the need for a repair. Another thing to look for is unevenly worn wheels, or wheels that are a different type or size. Your saw's wheels need to be the same in order to ride level with the cutting surface.

2. Daily greasings. "The bearings should be lubricated daily with just a shot or two of grease," says Randy Zea with Stone Construction Equipment, Inc. "Most people do this only monthly."

3. Air cleaners. Air cleaner maintenance changes according to whether you're cutting wet or cutting dry.

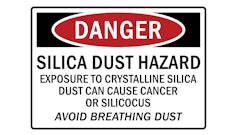

"You need to maintain a maintenance schedule either way, but in dry cutting of course you're dealing with dust," says Jeff Arnswald from Multiquip. "Dust of course gets lodged in air cleaners and is tougher on belts and bearings so it needs to be cleaned and maintained on a daily basis."

Arnswald says with wet cutting, air cleaners need to be checked only once a week.

4. Engine oil. "Oil levels should be checked daily," Arnswald says. "With dry cutting, you may need to change oil more frequently than you would with wet cutting just because of ingestion of dust in the engine."

5. Check belt tension. "Belt tension is the most important part of maintenance on the saws," says Zea. "If the belt happens to slip, the saws can vibrate dramatically."

Vibration can lead to premature wear to components, damage to the saw's frame, and reduced blade life.

"One of the things that is often overlooked is when new belts are installed," adds Ray Coblentz at EDCO. "New belts will stretch after an hour or so of use and need to be re-adjusted."

Maintenance made easy

A common trend across the pavement maintenance industry is building machines with maintenance ease in mind. When maintenance is easy to do, it's more likely that a saw operator will do it. Most saw manufacturers build their equipment with easy-to-reach fuel filters, oil filters, and grease zerks. Most saw manufacturers also install a depth stop on their machines to prevent the blade flanges from being bottomed out on the cutting surface. These stops should be inspected for proper performance.

"These stops can be bent, broken, or removed and need to be repaired or replaced to keep this from happening," Coblentz says. "Sometimes the outer blade flange is misplaced and the wrong size substitute is used in its place. This will cause the blade to be unevenly supported and the blade will start cupping or bowing."

At Multiquip, the 3-speed and 4-speed Street Pro saws are equipped with a self-lubricating blade shaft, which takes some of the maintenance responsibly off the shoulders of the operator.

"On the larger machines — the SP3s and SP4s — we offer a permanently lubricated blade shaft, which means you do not have to grease it at all," Arnswald says.

Caring for the blade

An important part of saw maintenance is making sure things are working properly in order to avoid damaging situations. When it comes to caring for the blade, there are several things to keep in mind. Ensuring that you have the right blade for the job is at the top of the list.

"The important thing to remember when using the saw is matching the blade to the application and letting the saw do the work," says Zea. "Use the correct blade for asphalt, green concrete, or cured concrete, additionally whether you're wet cutting versus dry cutting. You want to let the cutting speed dictate your travel speed, and not force the machine through the cut."

Coblentz notes that picking the right diamond blade for concrete cutting might be tricky.

"Blades for concrete can vary based upon what part of the country you are in because of the aggregate used in the concrete mix," he explains.

Proper blade care is also important. Protect it from nicks and bending during transport, and make sure working conditions for the blade are ideal.

"If it's a wet cut blade, they definitely want to make sure they've got proper [water] flow," Coblentz says. "And there are two of those coolant tubes, one on each side of the blade, and sometimes one of them could be damaged or pinched shut and you only get water on one side."

If you want your saws and blades to be taken care of properly, take time to train your saw employees on maintenance topics. Multiquip's Arnswald offers another nugget of advice for saw maintenance, which seems simple but is often overlooked.

"Keep the machine clean," he says. "Normal wear and tear is always going to be there, but a lot of what you see is just because the machines aren't kept in a relatively clean state. Keeping the machines clean helps the machines live longer, and helps the parts live longer. So a daily power washing makes life easier for when maintenance does have to occur."