Striping machines are basically simple pieces of equipment, essentially using pressure to apply paint to pavement. But like any piece of equipment, airless stripers can be used effectively and efficiently, enabling you and your crew to reach your peak productivity — or they can be used inefficiently, often reducing productivity and even shortening the life span of the machine.

Following are some approaches I take in my striping business (accompanied by explanations of other industry veterans) that will enable you to get the most out of your striping equipment.

1. Set equipment up right. Striping success starts with how you set up your machine each day: After circulating paint through the system, reduce the pressure setting to the lower end of the machine's range. Then install the spray tip and place the gun in the holder with the tip about 5 in. above the pavement. Roll the striper onto a piece of tar paper or other scrap material, and make a test spray of a few inches.

The spray pattern will be uneven because the pressure is too low. You will probably see a heavy amount of paint in the middle of the line, and a "tail" of paint on the edges. Increase the pressure in steps, test spraying each time, until the pressure is just high enough to properly atomize the paint and create an even spray pattern.

Once this pressure is reached, there is no advantage to further pressure increases. Adjust the position of the gun to get the desired line width, and you're ready to stripe.

2. Monitor your engine and pump pressure. "Most people run their throttle and pressure too high," says David Basile, foreman for my company, Robert Liles Parking Lot Service. "That's hard on the equipment and wastes fuel."

So don't run the engine wide open! Slow it down, as long as it runs steady and the pump keeps up. Depending on the type of machine you have, you might find that you get a more even line if the engine is running slowly.

On an airless machine with a piston-type pump, for example, the engine speed should be adjusted to the flow rate of the spray tip. In other words, it will need to run faster for a 3-21 tip than for a 3-17 tip.

3. Invest in spray tips of different sizes — and keep them handy. Most stripers know that they can vary the amount of paint they apply by adjusting the pressure on their machine. But a better way to change the amount of paint you put down is to change the size of the tip you use.

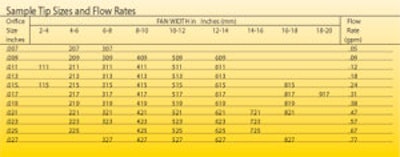

Tip nomenclature varies slightly among different companies, but in general the first number indicates the width of the spray pattern, and the second number indicates how much paint will flow through the tip at a given pressure. For instance, a 4-17 tip will paint a wider pattern than a 3-17, and a 3-21 will put out more paint than a 3-19. If you are painting long stripes, or a large parking lot, use a large tip like a 4-21. This will allow you to travel at a higher speed while still applying the proper amount of paint.

On the other hand, if you are painting curbs, a small parking lot, or curved lines and want to travel slowly, switch to something like a 4-15 tip so the paint won't build up too thick.

Different size tips will allow you to regulate the rate of application while keeping the optimal operating pressure, so don't adjust the pressure to vary the amount of paint you apply — change your tip. And, to make sure you can change them when you need to, make sure each crew has a selection of tips available on each truck. We store our spare tips in a "tip bucket" — a plastic container with a little mineral spirits in it so that paint does not dry inside the tip, and it will be ready to go when you need it.

"We like to use a narrow pattern tip like a 2-19 so that we can paint with the gun mounted higher and still get a 4-in. line," Basile says. "This allows the tip to clear some obstructions and makes the width of the line vary less on uneven pavement. On the other hand, on windy days I will put in a wider tip like a 4-19 and lower the gun so that I paint a sharp-edged line without overspray caused by gusty wind."

4. Change tips when using driven machines. When using a Line Driver or Lazy Liner, consider using a tip with a narrow pattern. Graco's Mike McGowan says that with a narrow pattern tip you can raise the gun an additional 2 to 3 in. and still get the 4-in.-wide lines you need.

5. Match the filter to the tip you are using. All airless machines have an in-line filter, which needs to be matched to the tip size. Basile says a 3-15 tip has a small opening that can be blocked by a tiny particle of dried paint or trash. "Always use a filter with at least 100 openings per inch (a 100 mesh filter) when you use a small tip like a 3-15," Basile says. "When you use a tip with a large opening like a 3-21 or 3-23, you can use a coarser filter like a 60 mesh, which will not need to be cleaned as often as a fine mesh filter.

"We keep our spare filters in the tip bucket so they are always handy."

6. Take steps to avoid clogged tips. Tip clogging is often blamed on dirty paint or bad tips. But Steve Trowbridge, Titan Tool director of product development, says that more often than not the problem is caused by a dried skin of paint on the inside surface of the hose. The dried film breaks free during use and those particles are what cause the tip clogs.

A good way to prevent this is to add a simple extra step to your normal procedure: If you leave paint in your machine overnight, the first thing you need to do at the beginning of each work day is crank the machine and raise the operating pressure to it's maximum level. Then, with the spray tip off the gun, release the pressure by spraying back into the paint bucket. The increase in pressure causes the hose to swell slightly, and this breaks the bond of the paint film to the hose and allows the potential clogs to circulate on out of the system into the bucket. Circulate the paint from the bucket, through the system, and back into the bucket for a few moments, reduce the pressure setting, and replace the tip on the gun. Any potential clogs will be caught by the machine's filter before they can get to the gun.

Trowbridge says contractors should rely on this same principle when cleaning the machine. After the paint has been flushed from the system and the solvent is circulating, raise the pressure, release the gun trigger (allowing pressure to build), and then squeeze the trigger so that the pressure is released suddenly. Repeat this a couple of times and your hoses and pump will be cleaner because the sudden changes in pressure will cause any dried paint to break free and travel out with solvent.

7. Optimize spray gun location. This is a sure-fire way to get the best results from your striping machine.

"Just because machines come with guns on the front right side does not mean that is the optimum location," McGowan says. "Sure, that location is best to get right up to the curb, but it falls short on curved lines and is not best for the straightest lines either.

"Front or rear guns have their place and each offers important benefits to your everyday business," he says. "Front-mount guns make it easy for you to get on the line but at the same time it is easy to get off the line as well. With rear-mounted guns, once they are on line they tend to stay on line."

McGowan says many contractors have learned that moving the guns on the rear axle delivers excellent, fluid lines while still excelling on jobs — such as running tracks — where perfectly straight lines are required.

"Somewhere between front and rear is a happy medium to gain the quick response of front guns versus the great tracking of rear guns," he says. "Sometimes you want more responsiveness and control; other times you want the tracking. Lately, I have been locating guns at the front of the rear tire to get the best of both worlds."

8. Set up your dual guns for greatest efficiency. If most of your jobs involve single lines, why put both guns on the right side? Mounting the second gun on the left side of your striper adds to the machine's versatility.

"A good example is when you are striping angled stalls on both sides of the parking lot and both sides ending at the curb," McGowan says. "Having guns on both sides allows you to instantly stripe either side right up to the curb. It also helps immensely when you have to work around vehicles in the lot."

9. If you are applying glass beads with a bead dispenser, measure bead door settings. Little can be more frustrating than having to remeasure settings each time you get on a job, and settings for doors on bead dispensers can be touchy. When you finally lock into an ideal door setting that delivers the proper amount of beads, measure it so that you can repeat or duplicate the same performance down the road. McGowan recommends using coins as a measuring device because they are effective and readily available to ensure repeatability from you or your crew.

10. Flush and store your machine properly — even just overnight. "Too many contractors store their machines improperly," says Paul Wood, export manager for Airlessco. "Leaving plain water in the machine, or worse, leaving it empty so that air is in the system can damage the packing and metal components." Wood suggests that contractors who primarily use waterborne paints should flush the system with clean water and then circulate either an environmentally safe antifreeze solution or a petroleum-based product like paint thinner or kerosene through the system. Products that mix with water and protect the interior of the paint system also are available.

"Some contractors ask if it is best to store your machine with solvent and under pressure," says Graco's McGowan. He recommends loading the machine with mineral spirits, circulating the mineral spirits to all points at low pressure, then shutting the pump off. Then open the prime valve to relieve all pressure.

"Never store your machine under pressure," he says. "Once pressure has been relieved, close the prime valve. Your wetted parts will be ready to work when you are with no surprises."

In fact, McGowan says, you should never leave a striping machine unattended while under pressure. "There is no gain in doing this," he says. "I believe this is still a throwback to the 'very old' days of all-leather packings to assure that they do not dry out. With today's packing designs this is not necessary."

It's a rule at Robert Liles Parking Lot Service that you never leave a machine unattended, even for a few minutes, with pressure on it. Someone could inadvertently bump the handle or gun and make a mess, or worse, it could be dangerous.

Robert Liles is owner of Robert Liles Parking Lot Service, a member of the Pavement Advisory Board, and a regular speaker at National Pavement Expo and National Pavement Expo West.