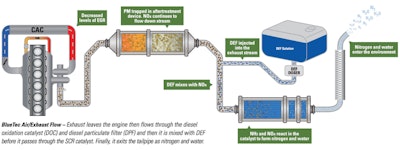

Modern medium- and heavy-duty trucks have sophisticated exhaust aftertreatment systems that can include a diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and selective catalytic reduction (SCR) system consisting of the SCR catalyst, ammonia oxidation catalyst (AOC), diesel exhaust fluid (DEF) tank, DEF injector and pressure and nitrogen oxide (NOx) sensors. (click on the system illustration below for a better view of specific information on these components.) While these systems require little maintenance, they cannot be ignored without costly consequences. This diagram of a 2010-technology Daimler Bluetec emissions system illustrates how a modern SCR system works.

This diagram of a 2010-technology Daimler Bluetec emissions system illustrates how a modern SCR system works.

Starting with 2007 model trucks, a DPF was added to remove particulate matter. “The DPF has two functions: to collect particulate matter and to store the residual ash after the soot has been oxidized,” says David McKenna, director of powertrain sales, Mack Trucks.

The DPF traps and removes up to 95% of particulate matter from the diesel engine exhaust. It contains a ceramic filter element that utilizes a honeycomb structure with long channels that are plugged off on alternate ends. Exhaust gas is forced through the porous channel walls, allowing the gas to escape through the neighboring channel wall while the particulates are trapped.

Over time, soot builds up on the DPF channel walls. The soot is cleaned and reduced to ash by heating either through passive or active regeneration. During this process, the heat inside the filter can reach 1,125° F.

Passive regeneration occurs automatically when the exhaust gases are hot enough during vehicle operation to cause a significant oxidation (a.k.a. burn-off) of the accumulated soot. Active regeneration injects fuel into the exhaust system to elevate exhaust temperatures and burn off soot collected on the DPF.

Volvo Trucks uses active regeneration on its pre-2010 technology trucks. “There is a seventh injector that sprays a mist of fuel downstream from the engine exhaust to the DPF during active regeneration on pre-2010 units,” notes John Moore, powertrain products manager, Volvo Trucks. While this system requires little in the way of maintenance, proper injector operation is critical. “If the seventh injector clogs and cannot burn the soot off the DPF, the filter will have to be pulled off the vehicle and cleaned using a machine, along with repairing the injector.”

Cleaning the DPF

The byproduct after regeneration is ash. “As the ash accumulates within the DPF housing, the effective filtering surface area is reduced, which can cause excessive active (fuel-consuming) DPF regeneration events,” McKenna points out. “Should the filter reach 100% of the design of the ash loading capacity, there is little to no filter area left to collect soot, and significant exhaust backpressure will arise.”

After many regeneration cycles, the ash begins to build up in the DPF and the ceramic filter must be removed and professionally cleaned. “Clean at the appropriate intervals,” advises Brad Williamson, manager of engine and component marketing, Daimler Trucks North America. “Don’t push the regeneration limits. Ensure the cleaned DPF meets the OEM specifications. If a DPF is not properly cleaned, it will have less efficiency and capacity.”

Volvo trucks recommends that the DPF on its trucks be cleaned at 250,000 miles, or 4,500 hours, whichever comes first. Performance will decline if the DPF is not serviced at the proper intervals. “Backpressure will continue to increase in the exhaust system, thus reducing engine efficiency and decreasing fuel economy,” says Moore.

Frequency of DPF cleaning intervals can vary. “This is largely dependent on the vehicle duty cycle,” says McKenna. “Trucks operating at highway (steady state) speeds for extended amounts of time can go as long as 350,000 miles. Whereas, a truck that operates in a steady stop-and-go (transient) duty cycle will not see that type of mileage accumulation before an ash cleaning is required.”

The 2010 technology trucks generally offer longer run times between DPF cleaning than the 2007 technology trucks. “For 2007 to 2009 engines, the ‘standard’ cleaning interval is approximately 300,000 miles, but this varies between engine families and by application,” says Williamson. “Engines built in 2010 and later raised the cleaning intervals to 300,000 to 400,000 miles, but again this generally depends on application and fuel consumption.”

No matter what the recommended interval, don’t ignore this vital pollution control device. If maintenance is not performed, the collected ash and soot can completely plug and destroy the DPF filter. This ceramic filter can cost $3,000 or more to replace.

“Yes, they are expensive, so handle with care,” cautions McKenna. “Do not drop or force the DPF element into the canister. You will end up with a very expensive piece of ugly ceramic art!”

Make sure the technicians who work on the DPF know what they are doing. “Follow proper operating and maintenance procedures outlined by the manufacturer and take it to a reputable shop for cleaning,” says Moore. “DPF substrates can be easily damaged if dropped during the cleaning process.”

If left untended, the DPF can create several issues. “Some of the consequences include the potential for being non-compliant with emissions regulations; cracking of the DPF; increased backpressure in the engine; the loss of power due to down rating; and potentially being down rated to a degree that will not allow the truck to perform at a level necessary to complete the job,” says Williamson.

Many vehicles will alert when the DPF needs to be cleaned via a backpressure monitor that lights up on the dash.

Take Steps to Reduce Ash Generation

Many variables can influence how fast the DPF fills with ash. These include factors such as oil consumption; not consuming oil at a rate greater than specified by the engine manufacturer; not using fuel or oil additives; avoiding long idle times; avoiding excessive start and stop driving conditions; and ensuring that you are using the appropriate CJ-4 oil.

Even oil change intervals may indirectly impact soot generation. “Fresh oil is much less likely to burn, but the same oil with 40,000 miles on it will,” says McKenna. “The oil control ring design is so good that most modern engines burn very little lube oil. However, when the oil wears out, it will get past the rings and burn off. The minerals that are in the oil are then collected in the DPF, adding more and unnecessary ash. I’m a firm believer that a regular factory approved oil interval is a very cheap insurance policy.”

“Reducing idle time definitely helps,” adds Williamson. “The cleaning intervals are not significantly reduced, because the cleaning of ash is based on the fuel used. The need for regenerations is affected by the time idling, the time driving, the temperatures, etc.”

Any reduction in fuel consumption also helps. “Soot is created during the combustion of diesel fuel, so any way that you can reduce fuel consumption will have a positive impact on ash cleaning intervals,” McKenna indicates.

This includes ensuring proper operation of the fuel injection system. “If there are issues with the fuel system (any component) that cause increased fuel consumption, then the cleaning interval will be decreased,” says Williamson.

According to McKenna, “This would probably have the biggest impact on DPF life short of a major turbo failure. A poorly maintained injector does not atomize the fuel effectively, and that would cause significant amounts of soot from poorly combusted fuel.”

SCR Requires Little Maintenance

SCR systems were added starting with 2010 model trucks. The use of SCR systems has extended DPF cleaning intervals.

“With EPA 2010, thanks to the addition of Mack ClearTech SCR, we’ve been able to dial the EGR flow rate back to something resembling the 2004 profile,” says McKenna. “The benefit of reduced EGR flow is the engine can breathe better and the combustion is much, much cleaner, meaning we create much less soot... than we did with previous [engine] models. Less soot production means less need for DPF regeneration, virtually eliminating the need for active DPF regeneration. This also saves a lot of fuel. Less soot production also means less collected ash, so we are thinking another 150,000 miles or more to a DPF element cleaning than for pre-ClearTech engines.”

There are only two serviceable items on the SCR system: the DEF filter and the DEF injector. The DEF filter is located at the base of the DEF module. The first cleaning should occur at six months and then annually. The DEF injector is located at the base of the DPF exhaust outlet. It should be inspected and cleaned annually.

Daimler Trucks North America has defined intervals for SCR system maintenance. It recommends checking/inspecting the system every 50,000 to 75,000 miles, which is consistent with most non-maintenance components, says Williamson. “The DEF filter needs to be changed every 250,000 miles for long-haul applications (150,000 miles for severe duty),” he adds. “The injector does not have a maintenance life — just check/inspect as needed.”

Other equipment, such as NOx sensors, are maintenance free and need no attention unless indicated by the onboard diagnostic system.

Keeping the current aftermarket emissions systems operating properly is not difficult. “Follow the factory recommended operation and maintenance procedures,” advises Moore. “If an emissions system problem occurs, have it fixed at an authorized repair facility immediately to avoid further complications. If the instrument cluster indicates DEF is low, fill the DEF tank right away.”

Simple steps can minimize downtime and prevent damage to expensive exhaust aftertreatment components.