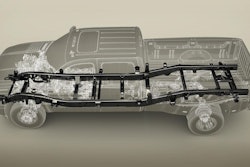

The 2015 Ford F-150, debuted at the Detroit auto show, uses cutting-edge materials and an industry-first frame design. Starting with the fully boxed frame, Ford engineers increased the use of high-strength 70,000-psi steel – from 23% to 77% of the frame – to improve stiffness and durability while reducing weight. The new frame is up to 60 lbs. lighter than the current frame.

Spec Sheet: 2015 Ford F-150 Pickup Truck

“Our frame team developed exclusive, industry-first engineering techniques to create a truck foundation that is lighter without sacrificing toughness,” says John Caris, F-150 lead frame engineer.

Ford engineers also increased the use of advanced materials in the F-150 body. High-strength, aluminum alloys are used throughout the F-150 body for the first time, improving dent and ding resistance, and also saving weight. The 2015 F-150 is up to 700 lbs. lighter than its predecessor, raising the truck's towing and cargo capacities, improving acceleration and stopping performance and making the truck more efficient. Military-grade aluminum alloys were selected because of the lighter metals’ unique ability to withstand tough customer demands, and they also brought aluminum alloys will not rust and are resistant to corrosion, .

“Our objective was to find materials that allowed us to design the truck to be as tough – or tougher – than the current model, yet could help it be hundreds of pounds lighter for better capability and fuel economy,” said Pete Friedman, manager, Ford manufacturing research. “Out of all the materials we tested, we carefully selected only certain grades of aluminum that met our high performance standards in all of our tests, while allowing us to trim hundreds of pounds from the truck.”

The reduced weight of the high-strength, military-grade, aluminum alloys enables the F-150 to tow and haul more than ever while also improving acceleration, braking and handling performance. Adding to these benefits, aluminum alloys will not rust and are resistant to corrosion, helping enhance vehicle life.

New Engine Option

There will be four engines available for the F-150: a 3.5L V6, a 5.0L V8, the 3.5L EcoBoost and an all-new 2.7L EcoBoost. The 2.7-liter EcoBoost with standard Auto Start-Stop is engineered specifically for the next-generation Ford F-150.The high-output twin-turbo 2.7-liter EcoBoost V6 delivers power and performance in a stronger, smarter package.

“We’ve applied lessons learned from the 3.5-liter EcoBoost to the new 2.7-liter EcoBoost, but with new technologies that make this more efficient engine perform like a larger mid-range V8,” says Raj Nair, Ford group vice president, global product development.

Boosting the 2.7-liter EcoBoost’s fuel efficiency is the debut of standard Auto Start-Stop technology in the F-150. This technology, specially tuned for truck customers, shuts off the engine when the vehicle is at a stop – except when towing or in four-wheel drive – to give drivers power on demand when they need it most. When the brake is released, the engine restarts quickly.

The 2.7-liter EcoBoost engine features the first use of a compacted graphite iron cylinder block in a gasoline engine, the same material used in Ford’s 6.7-liter Power Stroke turbo-diesel V8 engine. The composite CGI/aluminum block saves weight while providing strength where it’s needed most for durability.

“Previous engine block design choices were high strength or compact or lightweight,” said Ed Waszczenko, engine systems supervisor. “We wanted to go further with the 2.7-liter EcoBoost and design an engine with compact structure and high strength and light weight.”

The 2.7-liter EcoBoost also features all-new engine logic that adjusts operating parameters on the fly to provide the best efficiency and performance for the environment and workload.

Engine ratings and fuel economy are yet to be released.

More Intelligent Features

Several new productivity features debut in the all-new F-150. They include:

- 360° camera view using exterior cameras to create a bird’s-eye view of the truck to help the driver park, maneuver in tight spots and navigate down narrow roads and trails

- Integrated loading ramps, which enable easy loading of ATVs, motorcycles and mowers

- BoxLink, which is a combination of metal brackets and custom cleats used to secure a variety of accessories in the cargo box, from ramps to storage bins to bed dividers

- LED headlamps and taillamps, which provide greater nighttime visibility

- Trailer hitch assist, a new rear view camera feature that adds a dynamic line based on steering wheel angle in the display to help customers line up truck and trailer without requiring a spotter or having to get out of the vehicle

- Smart trailer tow module using an all-new smart trailer tow wiring harness that helps identify and inform the driver of potential trailer connectivity issues, burned or unlit trailer marker lamps and brake light and trailer battery faults

- Remote tailgate allowing for the tailgate to be locked, unlocked and released with the key fob – eliminating manual locking and increasing convenience and security; the tailgate also is damped, dropping down, hands-free, to a flat position when opened

- High-wattage power outlets (400 watts, 110 volts) in the cab that allows drivers to easily charge corded tools, battery chargers or mobile devices on-site or while driving

- LED spotlights on sideview mirrors, which provide powerful, durable and bright lighting around the truck exterior

- Latest EcoBoost technology in an all-new, even more efficient 2.7-liter EcoBoost engine that features extremely high output and lightweight design

- Next-generation tailgate step, which is now fully integrated inside the tailgate and virtually invisible when not in use