Shaw Brothers Construction in Gorham, ME, has been in the road building industry since 1977. The company started with two brothers, Dan and Jon Shaw, a handshake and a backhoe. Their commitment back then to working hard and satisfying the customer is still the backbone of the company today, which has become one of Maine’s largest earthwork contractors. Over the years, over 800 commercial projects ranging from $5 thousand to $15 million, have been completed in the 100-mile radius they serve surrounding the Portland, ME area.

After 35 years of focusing on heavy highway, utility, municipal work and sub-contracting out asphalt lay down, the company decided to cut out the middle man and look into building their own asphalt plant.

“In 2013, due to the amount of road paving work as compared with road reconstruction work, we decided to open the new facility,” says Mark Barnes, project manager at Shaw Brothers. “The future highway public work in Maine will be road resurfacing rather than full reconstruction.”

Constructing the past

Before venturing into asphalt production, their focus has been mainly on earthwork and road reconstruction. The company owns over a dozen active pits and quarries, totaling over 1,200 acres of DEP-permitted resources. Not only do their quarries produce all of the aggregates they need for their daily construction activity, the company also provides more than 20 types and sizes of aggregates to other companies throughout the area.

“Products include unscreened and screened sand, private gravel to any MDOT material spec, and crushed stone from 1/4 inch to 8 foot stone,” Barnes says. “We also sell many recycled products including screened loam, erosion control material, and three sizes of reclaim made from crushed bituminous asphalt.

“We are very proud to have worked and continue to work with some of the largest and best advanced private companies in southern Maine. (LL Bean, Unum, Texas Instruments, Sappi, Poland Springs and Wal-Mart). We work for all the major utility companies (Central Maine Power, Unitil, Portland Water District, Maine Natural Gas, Iberdrola USA). We also do a lot of work for local municipalities and have completed hundreds of projects for the Maine Department of Transportation and the Maine Turnpike Authority,” says Barnes.

Paving the future

In the spring of 2013, after six years of manufacturing asphalt through its subsidiary, Commercial Paving, LLC in Scarborough, ME, Shaw Brothers has made a major commitment to expand its paving operation by producing and laying pavement down themselves.

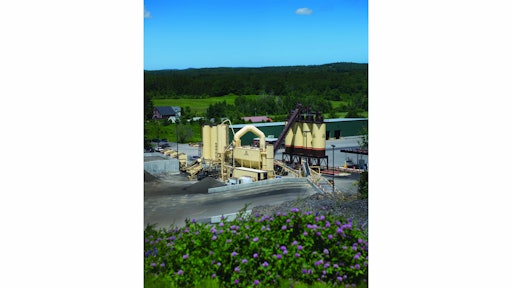

The old plant, a small 120-tph ADM drum plant, was producing 70,000 to 80,000 tons of asphalt per year. The new 400-tph Astec drum plant will produce up to 3,000 tons of mix in an eight hour shift. Shaw Brothers also added a state of the art dust removal system, Illinois Dust Around System.

Using the newest technology, an upsized bag house, and burning natural gas, this new plant is considered to be one of the most environmentally friendly plants in Maine. The natural gas fired plant is located on 2.9 acres of land at the Shaw Brothers' headquarters. This location also includes their B pit/quarry with over 5 million yards of aggregates.

Barnes says that having all materials in one location will allow them to be a low cost provider and will also save an enormous amount of trucking emissions that would be generated by hauling the raw products to the plant. With a 400-ton-per-hour production rate and four storage silos, this plant will have the capacity to service all customers in Southern Maine with their choice of hot mix.

“All the mixes will be Superpave designs and we anticipate having up to 25 different mix designs so we can supply the best mix for each specific application,” Barnes adds.

The new plant also includes four 200 ton silos, eight cold feed bins and three rap bins. “Our location is permitted for 24/7 operation 365 days per year,” Barnes says. “Also we included a state of the art Illinois Dust Around System, which will allow us greater flexibility in producing Maine Department of Transportation Mixes. We also have 30,000 gallons of upright liquid asphalt storage capabilities.

“Asphalt is the country's number one recycled product, and with our new plant we will be able to add up to 50% recycled asphalt into the mix designs on various projects. We plan to be in the asphalt business for a very long time,” Barnes adds.

Shaw Brothers has understood from the very beginning that no matter what they purchase or how good it is, it always comes down to people. This presented a challenge to the company’s new venture, Barnes says. “Finding and employing experienced people who will help us with quality control and lay down operations has been a challenge,” he adds. “We know we have a long way to travel, but we intend to learn along the way and we will become good at producing and laying down asphalt.”

“This will open new avenues for Shaw Brothers and its future work,” Barnes says. “We will now be able to self-perform our own paving on our earthwork projects. The plant will also become an outlet for our millions of yards of aggregates located adjacent to the plant. We believe that looking ahead the infrastructure that we now have will be maintained (milling, repaving, etc.) possibly more than new heavy highway construction as we continue to move into the future.”