Many installers of concrete floors, in both private homes and commercial facilities, are the first ones asked when customers want to know how to clean and care for their new concrete floors.

In commercial locations, contractors can expect such questions from cleaning professionals as well. Custodial workers are very familiar with vinyl composition tile (VCT) floors, and most have worked with different types of stone floors or terrazzo, which is in the concrete floor family, but they are less familiar with maintaining polished and unpolished concrete floors. Invariably, the building managers who are their customers will give the cleaning professionals your name—as the installer—for instructions on care and maintenance of their new concrete floors.

It's necessary for contractors to have a good understanding of how to care for the floor once installed.

Daily cleaning

If no finish has been applied to the concrete floor, all that is generally needed is that the floor be dust mopped and damp mopped using a neutral-pH cleaner. Because there usually are no grout areas, no grout cleaning is necessary.

However, contractors should encourage their customers to use backpack vacuum cleaners instead of dust mopping the floor. Dust mopping generates a lot of airborne particles that can be harmful to the cleaning worker and building users. Plus it has a tendency to push dust and debris from one floor area to another. A new generation of light and comfortable backpacks has been introduced that pull soil and debris from the floor, instead of pushing it around. This is healthier for the cleaning worker, building users, and more effective as well.

On large concrete floor areas, like those in a grocery store, an effective automatic scrubber should be used. A fully automatic floor scrubber is designed to apply cleaning solution to the floor, agitate or scrub it, wet-vacuum it, and then squeegee it dry, all automatically and all in one pass. Should cost issues arise regarding purchasing one of these machines, mention to your customer that in most cases an automatic scrubber can pay for itself in a few months because it improves worker productivity so significantly. After that, it pays dividends.

Interim cleaning

Interim cleaning is necessary if a sealant and/or finish has been applied to the floor and installers are encouraged to suggest to their clients that a sealant specially designed for concrete, and possibly a floor finish, be applied to the floor.

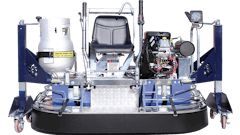

Interim cleaning also involves burnishers if a high-speed floor finish has been applied to the floor. A burnisher is a high-speed floor machine used to polish and clean floors. The machine not only removes surface level marks and soils but leaves the floor with a “wet look” shine. While they come in different sizes and with varying features, an effective burnisher for larger commercial locations would have the following attributes:

- 2,500 RPMs (rotations per minute)

- Adjustable pad pressure (up to 30 pounds); more pad pressure may be needed to remove more difficult soils.

- Variable speed control, to address the needs of different floors and their finishes.

- A built-in vacuum; this helps prevent dust from being inhaled by the user or released into the environment.

- Battery powered provides the user much greater flexibility and maneuverability.

- Auto-motion propulsion provides a gentle push assist, reducing worker fatigue and improving worker productivity.

In many facilities, floors are burnished every evening while in others floors are burnished less often, perhaps weekly or monthly. Contractor's whose customers want a high-gloss shine on their concrete floors are encouraged to suggest that the floors be burnished frequently.

Restorative cleaning

Restorative cleaning is typically necessary once or twice per year, however restoration cycles can be postponed if the two steps just discussed are performed regularly and properly. Restorative cleaning is labor intensive, which makes it costly. It can also be potentially harmful to the environment. For both reasons, many end-customers prefer to delay the procedure. When a floor is restored, a low-speed floor machine (175 RPMs or 350 RPMs) is used to strip and remove all finish (or sealant) from the floor. It is an involved process with many steps; however, once it is completed, the concrete should look much as it did the day it was installed. The next step is to reapply sealant or finish. In most cases, if a sealant is used, two thin applications are necessary. Once it has thoroughly dried, three to six thin coats of floor finish can be applied to the floor on top of the sealant. The more thin coats applied, the greater the shine.1

Contractors are advised to suggest one more thing to their customers: select trained floor care technicians. Floor care and maintenance is an involved, complicated process. A trained technician will know how to address most challenges and will keep your customer’s concrete floor looking its very best.

Ed. Note: Sean Martschinke is a CIMS ISSA Certification Expert (I.C.E.) and the product manager for Tornado Industries, a manufacturer of professional floor care equipment as well as other cleaning tools and products. He may be reached through Tornado’s website at www.tornadovac.com.

References:

1. Some floor finishes are made for low speed floor machines and others are made for high speed burnishers. It is very important to select the proper finish for the floor machine used. A burnisher used on a low-speed floor finish will likely remove most of the finish.