Kevin Parr has been a contractor for 40 years. His experience as a contractor led him and Jimmy Schau, a Union Laborer of Local 1149 to engineer and develop Green Key Telescoping forms.

“Over the years we had trouble finding straight lumber or lifting heavy pieces of steel formwork,” Parr says. “Jimmy and I continued to discuss better ways for concrete forming, and we came up with this telescoping form with a built-in key way made of lightweight materials that eliminates the need for saws, fabrication and attaching a key way.”

Parr says he and Schau were working on a jobsite getting ready to place concrete. The concrete truck was backing in to position and accidentally busted a wood form along the edge of the slab. While the crew scrambled to fix the form, Parr and Schau decided there had to be an easier way to building concrete forms.

PVC, the material of choice

Green Key Telescoping Forms are comprised of a PVC material with offered the strength and rigidity needed for a form. Parr says one of the challenges in creating these forms was the need to keep the weight low. “A typical 10 foot steel section of forms will weigh around 40 pounds. A 16 foot section of the Green Key Telescoping Forms weighs just under 14 pounds.”

Parr says one of the other aspects that came into play when developing the product was using a plastic material. He says by virtue of the material, they were cutting down their carbon footprint. In doing so, it has allowed Parr to submit the forms to the United States Green Building Council (USGBC) for consideration to be accredited to earn LEED points.

“Based on the fact we have a recyclable product which cuts down on construction site waste and is a made with renewable materials, makes it a desirable option to get those credentials,” he says.

The product is waiting to be evaluated by GreenSeal. “Because there is nothing else on the market like this, the organization needs to find something to compare it with,” Parr explains. “Considering that this product is going into a building and back out again, gives it a different qualification angle.”

Telescoping form

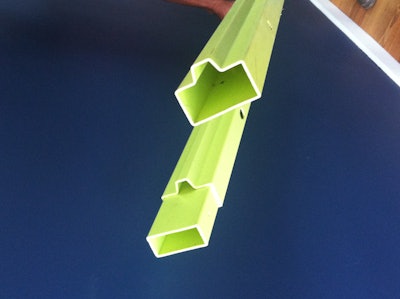

The outer section of the form is designed to hold the inner section in two-, four-, or eight-foot lengths. You’ll notice one side of the form is smooth for edge slab applications and one key way side is designed to be used for construction joints. Standard ¾” nail pin holes are pre-drilled in the section.

The inner section of the form fits in the outer section to extend the form up to 16 feet if using the eight foot lengths. The two foot section will extend to four feet and the four foot section will extend to eight feet. For convenience, the inner section includes a thimble on each end to attach in order to maintain a flush top and face.

The forms are currently available in standard four inch height and they are taking orders for their new six inch line which is currently in production. They should be on the market by the end of the year.

Considering safety

Take a look at the telescoping forms and at first glance, you’ll notice the fluorescent green color. That is no mistake. In fact, Parr says the color of the forms serves a unique and distinct purpose. “One of the issues when constructing large slabs, is sometimes the contractor needs to be out early in the morning to beat the heat. If it’s early in the morning, it may still be dark out, these form glow in the dark. You might not see the concrete you’re pouring, but you’ll see the form.”

Benefits to the contractor?

With the Green Key Concrete Forms, Parr says there are numerous benefits for contractors to use this type of forming system. Transporting the forms requires no special truck. A regular pickup truck with an eight foot bed and the tailgate closed will easily transport the forms and the contractor will save space as opposed to other forming options.

Given the PVC material, the forms are lighter to carry on and off the jobsite.

Installation becomes quicker and easier than traditional wood forms. “With wood you have to fight the twists and bows,” Parr says. “With these forms, it is totally possible to stretch them out, extend to the second piece and begin working. All a contractor needs to do is align the thimble with the next set and everything stays nice and straight.”

The forms are manufactured within an 1/8 inch tolerance. “This makes it easy to get an 1/8 inch straight when installing the forms. In the time it takes to get wood forms straightened versus these forms, you will save time,” explains Parr.

The key way of the form is molded on one side, eliminating any work needed to obtain key way specifications. This feature alone will save enough money in labor and material to pay for the forms. The key way allows contractors the ability to interlock slabs.

Finally, Parr says, decorative concrete contractors who are involved in stamping and staining work will find the Green Key forms a useful addition to their tools of the trade. “This is an excellent product for the stamping segment of the industry. The PVC does not absorb the dye or coloring and washes off with water. Contractors will avoid the chance of color bleeding when used on another project.”

According to Parr clean-up and maintenance is quick and easy. Prior to placing the concrete, Parr says both sides of the form is sprayed with WD40 (or some other release agent). The concrete will not stick to the form if this is done prior to the placement.

“When you strip the forms the next day, clean-up is performed by using a foundation brush and brush off any residual concrete. Slide the forms back together and you’re done.”

The PVC material creates a surface that concrete will not stick and can typically be wiped clean.

One contractor’s experience

General contractor, Mike McAvoy of T&M Construction, Seguine, Texas owns four, eight foot sections which extend out to 16 feet each piece. “Time is money and a contractor will save both. Considering set-up time and clean-up time, these forms cut both by at least a third.”

McAvoy says learning how to set them up was fast and easy. “The most impressive thing I was struck with was how easy they come off when it’s time to strip the forms. Typically, a contractor has to beat on the form and scrape the form to get them to release from a slab. With this, literally, a contractor pulls the pins off and they fall off the slab. It’s that easy.”

McAvoy also says he likes the versatile nature of the forms. “I like the fact that one side is smooth and the other side has the key way in it. There’s always a situation where a contractor is going to have to put quite a few key ways in a job. This is one set of forms that does it all.”

Ed. Note: For more information, visit www.greenkeyconcreteforms.com or direct at (740)827-3635.