The challenge:

Building an 802-foot-tall skyscraper in San Francisco required a crane with very high lifting capacities covering a wide working radius and fast line speeds, while at the same time being as space-saving as possible.

The players:

Maxim Crane Works L/P.

Level 10 Construction

The process:

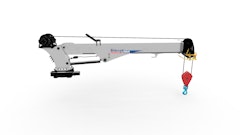

A new attraction is rising on the San Francisco skyline in the form of the 802-foot-tall skyscraper 181 Fremont Street. The project required a crane with very high lifting capacities covering a wide working radius and fast line speeds, while at the same time being as space-saving as possible. The WOLFF 700 B luffing jib tower crane — manufactured by WOLFFKRAN and owned by crane rental company Maxim Crane Works L.P. — fulfilled all technical demands made by the contractor, Level 10 Construction. It is the first of its kind in the United States and stands for the launch of a new generation of high-performance, fully electric WOLFF luffing jib cranes on metropolitan high-rise construction projects in the U.S.

Following an intense collaboration between all three involved parties during the planning phase, the WOLFF 700 B finally set off on its journey from the production facility in Heilbronn, Germany, to San Francisco late 2015, where it has been in operation since mid-January.

The WOLFF 700 B features a maximum lifting capacity of up to 110,230 pounds in three-fall operation and a maximum tip load capacity of 36,380 pounds at a jib radius of 164 feet.

The heaviest lift on the site is a mega support column weighing just over 100,000 pounds set at a 46 foot radius. But the crane also has to handle heavy loads further out due to the exoskeletal design of the high-rise using heavy steel support columns on all six corners of the building.

Despite its remarkable power the WOLFF 700 B stands on a surprisingly slender tower, with section dimensions of only 7 feet 7 inches, allowing for transport on regular trailers without any special road permits required.

The fully electrically operated crane is equipped with a stepless frequency controlled drive, making it a true leader in terms of energy efficiency, both compared to electric cranes without FC drives and even more so compared to diesel-powered cranes. Needless to say, the comparatively low noise emissions and complete absence of pollution are of undisputed value in densely populated urban areas.

For a crane of this size category, the WOLFF 700 B also stands out in terms of its compact design and maneuverability, which is another big plus point on the 21,528-square-foot plot in the densely built SoMa district. Of particular mention is its short counter jib with only 25 feet 3 inches. Originally developed for the installation of wind turbines, WOLFFKRAN now fits the 700 B with the short counter jib as standard, allowing for an even closer positioning of the crane to the building.

But the WOLFF 700 B is also space saving during the crane assembly. Thanks to WOLFFKRAN’s patented design of the counter jib, individual component weights can be kept low and smaller mobile cranes used for the assembly.

Further, the pre-assembly of crane components before their arrival on the site significantly reduces assembly time, which in turn keeps road closures to a minimum. The 700 B on the 181 Fremont construction site was completely assembled in just three days.

The WOLFF 700 B will be climbed externally alongside the building to a final tower height of 764 feet. Despite this remarkable tower height, the crane will only be tied to the building 10 times, thanks to the extremely sturdy, but comparatively slender 7-foot 7-inch WOLFF HT 23 tower sections.