In an industry where two-thirds of construction firms (69%) report they are having a hard time filling hourly craft positions in the construction workforce, many firms are changing the way they pay and operate to cope. A recent industry wide survey from the Associated General Contractors of America is warning that labor shortages could undermine broader economic growth and are calling for new workforce measures to improve the pipeline for recruiting and training of new craft workers.

With this in mind, it’s now even more critical than ever to not only find the right workers for your business, but to properly train them for long-term employment.

You Can’t Train the Wrong Person

Millennials now make up the largest, most educated and diverse generation in history, and just surpassed Gen X as the largest percentage of the workforce. Unfortunately though, these candidates don’t always have the experience that owner operators are looking to hire. Many contractors are finding that it’s not always the experience that makes a good worker, it’s the attitude.

“We hire for company culture, not the best resume” says Pete Phillips, president of Clean Sweep, Inc. “Integrity, excellence and teamwork are the main three things we hire for. Those are non-negotiable. If you don’t have integrity, if you don’t do excellent work and you’re not willing to be part of a team then it doesn’t matter who we train, it’s not going to work out.”

Phillips said his company started out hiring people based on their skillsets, but found they were firing more employees than they were keeping because they didn’t fit into the culture of the company.

“Through our hiring process, we now make potential employees jump through hoops,” Phillips says. “If they’re not willing to work hard to get a job, they won’t be willing to work hard at a job.”

When looking for a potential employee, the company lists job openings on job boards like Monster and Craigs List. They send those candidates to one website, ApplicantPro, where they complete a customized personality test to ensure they will be a good fit for the job. The questions will figure out if they like to work alone, at night and without much supervision.

“If a candidate requires a lot of interaction and human contact, they’re not going to stay at this job,” Phillips says. “The personality test helps see if the candidate is a good fit before we even make an offer to interview them.”

During the interview process, Clean Sweep has the candidate go through assessments that include sorting exercises and a driving test, along with “knock-out” questions that will immediately disqualify a potential employee from being hired.

“You can’t train the wrong person,” Phillips says. “Figuring out who the right people are for your company and getting them hired is the first step in any successful training program.”

Train for Skill

Like with any new hire, Clean Sweep starts their employees out by watching videos. New hires watch videos on the company vision and culture to reiterate what is expected of them.

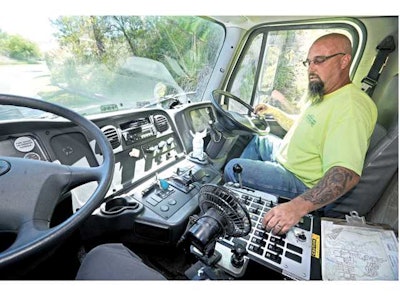

Drivers are then brought in on a day time crew to learn truck orientation, pre-trip inspections and to learn routes and procedures.

“That driver learns how the truck works, where the schedules are, where timesheets are, where incident reports are, here’s what to look for in the truck, etc, all during the day time,” Phillips says. “Then we put them in the truck and behind the wheel with a trained operator.”

Clean Sweep then brings out the W.O.W. sheet. This document is a schedule of what a sweeper operator should know Within One Week (W.O.W.). According to this schedule, after that first week, an operator should:

- Be able to pass a base line driving test

- Complete and train on daily check lists

- Be able to pass a “how to sweep” test

- Have a functioning knowledge of all truck controls

- Be able to Train the Supervisor on control of trucks

After week one, there are three other W.O.W. sets to complete for the first month of training. “No driver goes out of here alone without at least 40 hours of supervised training,” Phillips says.

Some of the things operators learn during these 40 hours is; how to keep obstacles on the driver side; how to run their patterns; how to watch the brooms in the mirrors to avoid drivers putting their head out the window; how to drive at optimal speed; how to make proper turns (not turning too fast); and educating the driver on how they are in control of fuel consumption and the general well-being of the equipment.

“We want to give them room to make mistakes, but we want to supervise those mistakes so they don’t become habits,” Phillips says. “The whole experience, the feel of the sweeper, the sounds, the smells, those are all things operators will only learn by experience and we give them that. There’s a lot of little things that make all the difference in training a good operator.”

Each employee is also issued what Phillips calls a “good strong employee handbook” and a playbook for each job.

“We put down in writing a how-to of the way we want each type of job done,” Phillips says.

Finally, before an employee goes out on their own, they sign a form indicating they are ready for the responsibility.

“We make employees sign off on their training for accountability and liability purposes,” Phillips says. “We want to know that yes they have been trained to use this truck, that they fully understand the function of it and they feel comfortable operating it.”

Staying Power

Once you have those employees on board and properly trained, you want to make sure they stay otherwise all these efforts have been for nothing. Phillips knows down to the dollar how much hiring and firing can cost the company and those dollars really add up.

“Training is expensive,” Phillips says. “You have the administrative costs, employee training, lower productivity costs and other expenses that all add up.

“It costs me $5,462 to hire and train someone, bad or good. If they’re bad, you just flushed that time and money down the commode.”

This is why Phillips emphasizes finding the right employees before spending you have to spend a single dollar on training them.

“We focus like a laser on the people we want. The idea is to cut down on training. Period,” Phillips says. “We hire good people, they stay. Treat them well. Pay them fair. It all goes back to the culture of the company.”

![Pavement Awards 2025[main]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2024/05/PavementAwards_2025_main_.665883e4276e8.png?auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=100&q=70&w=100)

![Pavement Awards 2025[main]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2024/05/PavementAwards_2025_main_.665883e4276e8.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)