We’re not even sure how many articles we’ve written about the asphalt industry turning to “green” solutions like cheese, plants and even pig poop to help improve both the sustainability and the quality of the roads we drive on every day. With this article, we add soybeans to that list, and for good reason.

Reduce, Reuse, RePLAY

RePLAY Agricultural Oil Seal and Preservation Agent by BioSpan Technologies is a patented solution that extends the life of paved asphalt surfaces when applied every few years.

By reducing moisture penetration and sealing hairline cracks, RePLAY actually reverses the oxidation process and protects asphalt from potholing, edge rutting and cracking. The 88% biobased solution, composed of North American-grown soybeans, is easily applied and cures within 15 to 30 minutes, saving the hassle of extended lane drop time and expensive labor.

"RePLAY doesn't dry out like other seals," says Dr. Shel Chesky, owner of BioSpan Technologies. "The unique nanopolymer technologies used in RePlay are responsible for extending the life of all asphalt pavements. It penetrates into the asphalt matrix between 1-in. to 1-1/4-in. within 15 minutes and unlike other preventive maintenance systems, there is also no need to re-stripe the pavement as the product won't damage the existing striping."

Another benefit? Skid-resistance of the pavement is actually increased with RePLAY.

"Within 15 minutes of drying, the product will grab your shoes," Chesky says. "It contains a natural rubber that we make from soybeans. It won't run off and will maintain, and even increase, the skid resistance of the asphalt whether it's wet or dry."

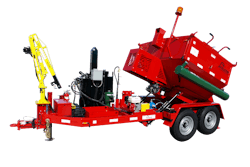

The product is applied using a computer controlled spray system that is mounted on the back of a truck. The system accurately delivers the amount of product that's needed for the surface in a uniform way.

"The 14-ft. spray bar ensures a uniform application," Chesky says. "The system is GPS guided and adjusts for speed and wind at an application rate of 0.015 to 0.030 gallons per square yard. This means just one gallon of RePLAY will cover between 50 and 66 square yards. A little bit goes a long way."

Chesky says statistically, the product is 40% less expensive that using traditional methods by year two. "And by year four or five, we've put so much more money back in the pockets of those that do the road maintenance that they are able to go ahead and do other things with that money," he says.

In addition, the product is 100% “green,” which is a growing trend in the industry adding pressure for asphalt contractors to produce in their products and processes.

"All the materials come from domestically grown sustainable materials," Chesky says.

In 2009, a Life Cycle Assessment was done for RePLAY where it was compared to a competitive petroleum-based product. The report determined that RePLAY has almost 40% more favorable total life cycle environmental performance as it is carbon negative.

"We are negative 400 tons of carbon per lane mile," Chesky says. "Compare that to a traditional petroleum based material that adds 1300 tons of C02 to the environment."

A Win-Win-Win

RePLAY uses about 200 bushels of soybeans per road mile which creates a win-win-win situation. The asphalt industry becomes even more sustainable, municipalities save money and farmers who grow soybeans reap the benefits as well.

Since 2012, the City of Hutchinson, MN has treated many pavements that are in excellent condition, or have been constructed within three years, with RePLAY.

“Our hope is that we can delay sealcoating, probably at a cost savings, and get many more years out of the ‘fresh’ road before we have to sealcoat,” says John Olson, Hutchinson public works manager.

“I look at these sealers as another tool to use in the fight to preserve pavements,” he adds. “I don’t think they will end up replacing traditional maintenance treatments, but will likely have an effect on when the traditional methods are first used.”

The Minnesota Soybean Research and Promotion Council is pleased to see communities consider soy oil-based products for street improvements.

“We’re always looking at ways we can expand market opportunities,” says Mike Youngerberg, Minnesota Soybean senior director of field services. “That’s why we have a checkoff in place, to increase the value of soybeans. We did that with biodiesel – started small and took it statewide and that’s what we’re hoping for here.”

Both Minnesota Soybean and the Agricultural Utilization Research Institute are hoping to get county or city engineers thinking about RePLAY.

“All we have to do is look at our own state transportation budget and what has happened there. We’re always short of money,” Youngerberg says. “Anything we can do to help preserve those existing roads that are out there is a benefit.”

RePlay has been developed for use on ALL ages of asphalt. Ideally, it should be applied when the asphalt is fresh, 0-4 years old; however, since it brings the asphalt performance back to 95% of new asphalt, it can be used on all asphalt, whether new or 20 years old as long as the asphalt is intact and not alligator cracking.

"It's not just for new pavement, it's for all pavement," Chesky says. "We're able to make tremendous use of the product in terms of extending the pavement life if it's applied every five years on a decent road. We can get 35-40 years out of a piece of pavement with RePLAY."

For more information on RePLAY, please visit http://replay.biospantech.com/what-is-replay

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?auto=format%2Ccompress&fit=crop&h=100&q=70&w=100)

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)