The construction of the new IGA Istanbul Yeni Havalimani Airport (IGA), located roughly 22 miles northwest of Istanbul, marks a special milestone for construction activities in Turkey. Built on a site of 18,900+ acres, it will be the largest airport in the world once completed in 2028. The floor area of the main terminal alone will cover 321 acres. Construction costs are estimated at $11.3 billion USD

The project is being built in four phases. The first phase – scheduled to be completed at the start of 2018 – began in mid-2014 with the earthworks. By summer 2016, a total of around 13,000 people and 2,000 construction machines were at work on the site at one time. The second and third phases will include construction of additional take-off and landing runways and another terminal by the end of 2022. Upon completion of the fourth and final phase, up to 3,500 flights will be cleared for take-off and landing on a total of six runways, linking Istanbul with over 350 destinations throughout the world.

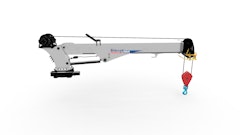

Among the equipment currently working on site are a total of 58 tower cranes. This proved a milestone of its own for Liebherr's activities in Turkey.

[Video] Liebherr Supplies and Supports 58 Tower Cranes on Istanbul Airport Project

Complex Project Requires a Complete Solution

The Liebherr Group has been active in Turkey for decades, originally working through local agents and direct with relevant manufacturing plants. As the importance of the Turkish market grew, Liebherr chose to open its own sales and service company, Liebherr Makine Ticaret Servis Limited Sirketi, in Istanbul eight years ago.

When Liebherr Makine Ticaret Servis Limited Sirketi was approached about supplying tower cranes for the IGA project, it acted quickly to coordinate with the tower crane operations in Biberach, Germany.

“Close support for the customer from the very outset is of central importance for the successful completion of a project of this scale,” noted Danyel Temizkan, managing director. “As a result of our long-term, close collaboration with the contractors involved, we were able to offer the possibility to provide required technical consultancy services to the customer from the very start.”

Clarification of the technical requirements, selection of the right equipment to enhance the site organization and coordination of commercial modalities were organized by Temizkan’s staff in close collaboration with their counterparts in Biberach.

“A great deal of expertise is required for major projects of this type to show how to use tower cranes efficiently,” said Dominique Tasch, managing director, Liebherr-Werk Biberach GmbH.

“To identify how to use the tower cranes most economically, the Tower Crane Solutions Department initially researched the relevant information relating to the complete infrastructure and the planned building complexes,” he explained. “The complete crane fleet was then planned on the basis of this building structure.”

After the technical issues were worked out by the Tower Crane Solutions team, the construction contractor and the dealer, negotiations started over the conditions for such a large package deal, which would consist of ten 154 EC‑H tower cranes, thirty-two 280 EC‑H tower cranes and seventeen 200 EC‑H tower cranes. In addition to price, negotiations included lead times, the availability of the defined range of services, spare parts supply and on-site service.

“Like the project as a whole, the time frame for the negotiations was very challenging,” Tasch stated. “We started the negotiations in March 2015 and were able to accept the order in mid-May 2015.”

The main criteria for winning the order included the capacity of the tower cranes, along with the extremely short lead times the company was able to provide. The first tower cranes had to be delivered at the end of June, just a few weeks after signing the contract.

The availability of both service personnel and parts on site was just as important as prompt delivery of the cranes. “We can ensure the maximum availability of all the cranes by having five fitters permanently stationed on the site,” said Temizkan. “In addition, to coincide with the delivery of the first tower crane, we established a spare parts warehouse specially compiled for the crane types in use, and stationed this warehouse on the site. This enables us to minimize the delivery times for spare parts.”

Liebherr is also providing 24-hour service with both local service technicians and service technicians in Biberach. Regular visits by technical personnel from the Biberach facility further ensure that the advice and training for the customer continues on an ongoing basis. “We also ensure the constant flow of information between the site and the plant,” said Temizkan.

Work at the massive construction site, which encompasses 36.7 million sq. ft. of closed area, continues despite the recent political upheaval and terrorist incidents in Turkey. Upon completion, the IGA Istanbul Yeni Havalimani Airport will feature six working runways, eight air traffic control towers, 165 passenger boarding bridges, 500 airplane capacity and rail-connected terminals spread over 70 million sq. ft. It will host more than 150 airlines have a total capacity of up to 200 million passengers every year.

Fact Sheet: Istanbul New Airport

Total Project Area: 76.5 million m²

Total Closed Construction Area: 3.5 million m²

Main Terminal Building Construction Area: 1,300,000 m²

Car park Construction Area: 700,000 m²

Car park Capacity: 18,000 vehicle

Terminal Building Concrete Amount: 1,000,000 m³

Terminal Building Ferrous Reinforcement: 180,000 ton

Terminal Roof Area: 450,000 m²

Terminal Front-Line Area: 500,000 m²

Daily Landing and Departure: 3,500 (total after phase 4)

Runways: 6 (total after phase 4)

Source: İGA

![[Video] Liebherr Shares Insights on Recent Technology Advancements](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/11/default.5820c4df4098e.png?auto=format%2Ccompress&fit=crop&h=75&q=70&w=75)