Haver & Boecker Niagara showcased new product updates at World of Asphalt, which took place March 29-31 in Nashville, Tenn.

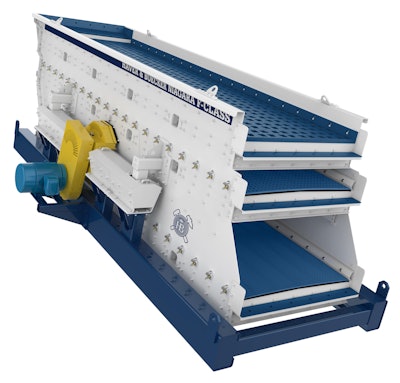

The company updated its Niagara F-Class Vibrating Screen with new technology for simplified maintenance and improved performance.Haver & Boecker Niagara

The company updated its Niagara F-Class Vibrating Screen with new technology for simplified maintenance and improved performance.Haver & Boecker Niagara

F-Class Vibrating Screen

The company updated its Niagara F-Class Vibrating Screen with new technology for simplified maintenance and improved performance. The new design retains the technical benefits the original F-Class is known for, such as improving performance in material stratification and reducing blinding and pegging.

The vibrating screen is now primarily manufactured with vibration-resistant lockbolts instead of the traditional welding used in previous designs. Lockbolts are more effective at maintaining structural integrity during the demanding load-bearing, high-vibration operation of a vibrating screen, while making maintenance more convenient, safer and cost-effective. Bar rails are now fastened to the cross beams with lockbolts, making them easy to exchange if they become worn. The robustness of the machine also permits cross beams to be positioned and lock-bolted every four-feet instead of every two-feet, allowing for better clearance and easier maintenance.

The new F-Class design provides the option to upgrade the machine with Haver & Boecker Niagara’s new Drop Guard system. The liners provide protection for the machine’s cross beams, both reducing wear and extending vibrating screen life. The blue liner simply drops over the cross beam with no adhesive or tools required.

Additionally, Haver & Boecker Niagara redesigned the flat deck models of the new F-Class to create the largest amount of open area possible for modular screen media. Featuring replaceable polyurethane anchors, the new high open area modular deck is suitable for virtually any pin and sleeve modular screen media. The polyurethane anchors are easy to replace and prevent premature wear on the deck frame. Additionally, the open design of the modular deck prevents material build-up on the bar rails.

Pulse Impact Test

Haver & Boecker added impact testing to its Pulse portfolio with experimental modal analysis. The impact test, also known as the hammer test or bump test, is now part of the company’s quality assurance program during factory testing, as well as on-site. This ensures each machine is properly tuned to avoid operating in resonance, ensuring efficient operation. With the opportunity to integrate impact testing data with other Pulse portfolio reporting and historical tracking, including Pulse Vibration Analysis and Pulse Condition Monitoring, Haver & Boecker Niagara can provide a more holistic view of the individual machine that helps customers maximize uptime through historical tracking. Haver & Boecker Niagara’s suite of Pulse diagnostic tools help operations to monitor the health of vibrating screens for optimum screening performance and equipment durability.

Operating in resonance can diminish productivity, incur damage to vibrating screens and pose safety risks. Impact testing involves striking the machine at key points with a dead blow hammer while the machine is off. It typically includes the four corners but can be expanded to additional areas. Collected data is analyzed to identify the machine’s individual natural frequencies. Based on results, engineers can adjust machine parameters to avoid these frequencies during operation.

Integration into the Pulse software opens up opportunities for easier on-site impact testing. Natural frequency can shift over time as components are repaired or replaced, resulting in irregularities that could translate into diminished performance, decreased efficiency, increased operating costs and imminent breakdown. By incorporating impact testing into Haver & Boecker Niagara’s signature Pulse diagnostics tools, producers can ensure optimum screening performance and equipment reliability.

The exciters are offered in four models, each of which is adjustable to provide eight weight configurations, offering the largest static moment range on the market.Haver & Boecker

The exciters are offered in four models, each of which is adjustable to provide eight weight configurations, offering the largest static moment range on the market.Haver & Boecker

Exciters

The exciters are offered in four models, each of which is adjustable to provide eight weight configurations, offering the largest static moment range on the market. Niagara Exciters come standard on all Haver & Boecker Niagara exciter-driven XL-Class and L-Class vibrating screens, and are also available as aftermarket parts for any brand of exciter-driven machine. Exciter-driven vibrating screens are ideal for high-tonnage applications and heavy-duty environments, such as dewatering or SAG mill screening, due to the equipment’s strength and advanced sealing system.

Niagara Exciters are engineered by Haver & Boecker Niagara to set the required stroke, frequency and exact static moment for each application, resulting in improved screening performance. The innovative design of the exciters and large number of weight configurations contribute to improved screening performance, including the largest number of static moment options on the market to handle high-capacities, minimal maintenance and long service life.

Niagara Exciters provide producers with reliable, consistent performance and require less downtime, resulting in more productivity and profits. The average lifespan of a Niagara Exciter is 15,000 hours, with some XL-Class exciter-driven vibrating screen currently operating at more than 40,000 hours. The exciters are fully supported by Haver & Boecker Niagara’s service and refurbishment programs.