The concept of 3D printing has been hovering around for some time now. The actual use of 3D printing and its adaption into the construction industry is now starting to become a reality. Architects and contractors around the world are beginning to build the first 3D residential structures including houses and apartment buildings.

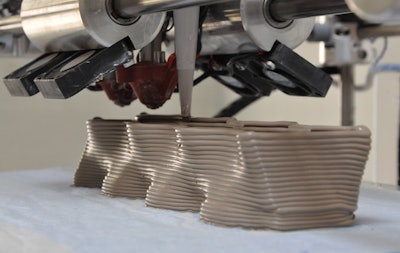

What makes 3D printing different than current construction methods? The 3D printing is done using super-size printers which use a special concrete and composite mixture that is thicker than regular concrete, allowing it to be self-supporting as it sets, according to Via Technik. So 3D printed components do not have the same design constraints that may hinder current construction methods. In addition, curved concrete structures created through 3D printing can be hollow, using less material and creating space for building services inside the structural elements.

Video: 3D Concrete Printing - The Future of Construction

Not only could this revolutionize the construction industry, but the less expensive process could also affect housing affordability. Lower material usage and lower labor costs create a less expensive construction method which can in turn create lower-cost housing.

Chinese company Winsun has already claimed to have built 10 3D constructed houses in one day at a cost of just $5,000 per house. In addition to making housing more affordable, many architects also hope that 3D printing will increase their ability to customize homes and buildings. Earlier this year, Winsun took its 3D printing construction beyond single houses, building a five-story apartment building and an 11,840-square-foot villa. Winston used a large 3D printer that fabricates the building parts in large pieces at the company's facility. Winston then assembled the pieces on-site adding steel reinforcements and insulation.

According to an article from CNET, Winsun says the 3D process saves between 30 and 60 percent of construction waste, can reduce production times by 50 to 70 percent and reduce labor costs by 50 to 80 percent.

According to an article from Business Insider, 3D printers build structures layer by layer. However, USC Professor Behrokh Khoshnevis hopes to extend the fabrication process even further with contour crafting. "Contour Crafting technology has great potential for automating the construction of whole structures as well as sub-components."

The Business Insider article also says Khoshnevis hopes to develop a gigantic 3D printer that could print an entire house in a single run including the structure and all its conduits.

Computerized 3D Construction Method Wins Global Design Contest

Architects in Amsterdam are also experimenting with 3D printing. The 3D Print Canal House is a research and building site that is using bio-based renewable materials to create eco-friendly, custom made architecture. Construction of the 3D Print Canal House is being done with each room being printed separately onsite and then assembled.

The 3D printing and construction project isn't just reserved to residential structures. Recently, a team of UC Berkely researches led by Associate Professor of Architecture Ronald Rael created a 3D printed free-standing pavilion they call Bloom. Bloom demonstrates the precision of the team's powder-based cement method of 3D-printed construction. Unlike other 3D printed structures which extrude wet cement, the UC Berkeley team's method involves printing thin layers of a special dry cement power. Each layer is then sprayed with water to help harden the structure. The UC Berkeley team claims their use of iron oxide free Portland cement polymer formulation and their system of 11 powder-based 3D printers can "create a more complex and precisely finished structure than the extrusion method and one which is reduced in weight and waste," according to an article about Bloom from Gizmag.

The evolution of 3D printing into the construction industry has both pros and cons. An article from NBS, which produces specification products for the construction industry, points out just a few of the possible benefits and downsides to the 3D printing in the construction industry.

Some advantages include:

- Faster and accurate construction – a 3D printer transfers the digital model into a physical one; errors that arise can only be due to faults in the digital model or the materials used

- Reduced labor cost – a 3D printer does most of the work with minimal human effort

- Reduced waste generation – components can be printed to order during the construction phase; those that are not used can be recycled

- Reduced health and safety risks – by replacing dangerous jobs on site with printing processes

- Environmentally friendly – recycled products can be used to produce the construction materials used in 3D printers.

Some disadvantages include:

- Reduced employee numbers in the industry, since the 3D printer does most of the work

- A limited number of materials can be used, since the same printer might not be able to print the required multiple materials

- Transportation – getting the printers for large in situ components to and from the site

- Storage of the printer on site

- Higher risks – any errors in the digital model can result in problematic issues on site during the printing/construction phase

- Conventional product manufacturing companies and plant renting companies could suffer as their products are no longer required

- Additional time may be required on site if the components are created in situ.

What are your thoughts on the 3D printing process and its implications for the construction industry? How do you see 3D printing to affecting the construction industry as a whole as well as your construction business? Is it a technology process you're considering for the future of your business? Share your thoughts below in the comments section.

And if you like what you read in this blog, remember to vote for us in the Jackson Design and Remodeling Blogger Awards for best construction business blog. Voting is open through April 10, 2015.

Go here to vote for ForConstructionPros

When your browser opens the page, scroll down to the Construction Business category (first box on the left in the second row). Click the radio button next to "ForConstructionPros" and then click "Vote." There's no registration required. You can vote once per category once per Internet-capable device you own.