Concrete and the cement that binds it is the most commonly used material in the world and the demand for it is growing. Unfortunately for the environment, the product is also very energy-intensive to produce, emitting about 80% of the cement’s weight in carbon dioxide during the production process and making about 5% of human-generated carbon dioxide each year.

This is why researchers are continually investigating ways to increase the performance of these materials while reducing the impact it has on the environment. Matthew P. Adams, an assistant professor of Civil and Environmental Engineering at New Jersey Institute of Technology (NJIT) has been investigating the use of recycled concrete as a replacement for natural aggregate in new concrete, an eco-friendly alternative that conserves natural resources and can reduce greenhouse gas emissions associated with construction.

“We examine the long-term durability of concrete materials to understand how the chemistry of the cement and concrete systems can be improved to provide better performance,” Adams says. “This includes looking at sustainable alternative materials for use in concrete such as recycled aggregates, partial replacements for cement with pozzolans, or alternative cement products. In general, improving the durability of our materials and reducing the materials with high environmental impacts will help us reduce our overall carbon footprint in the built environment.”

Cutting the Carbon

One of the best ways to reduce the carbon footprint of concrete is to reduce the amount of portland cement used in the product. Portland cement has a large carbon footprint because the production of it not only requires the burning of fuel to heat up the raw materials to make cement (which produces CO2) but heating up the raw materials also causes them to off-gas CO2.

“While portland cement is the glue that holds everything together, we can partially replace the material with other things and still create high quality, or in some cases, better quality, concrete,” Adams says.

His team is using pozzolans such as fly ash (a by-product of the coal burning industry) or calcined clays (clay that has been processed with heat treatments), or blast furnace slag (a by-product of the steel making industry) as binder.

Adams says calcined clays are specifically helpful in reducing the carbon footprint of concrete production.

“This is a normal clay that is heat treated to around 600 degrees celsius,” he says. “This material can be used as a replacement for portland cement in concrete. Clays are a material that is readily available all around the world, and the low burning temperature means that its CO2 production is quite low compared to natural aggregate concrete. Research is showing that this material may actually help improve durability of concrete in some cases as well.”

Recycle to Reduce

Every industry is trying to increase their use of recycled materials and all over the world different types of recycled materials are being used to increase recycled content in new concrete.

“Aggregates (the gravel and sand in concrete) make up 60-75% of the total content of a concrete mixture,” Adams says. “While their carbon footprint is low compared to cement, the volume of aggregates we use means that it is still significant. Much of the carbon footprint for aggregate use comes from the need to transport aggregates long distances from the quarry to the concrete production yard. In big cities, quality aggregate quarries are starting to be depleted, and so concrete producers must ship in aggregates from further and further away, increasing the transportation cost and carbon footprint of this material.

“At our lab at NJIT we are specifically looking at using recycled concrete aggregates (RCA) in new concrete. While we know that using recycled concrete aggregates in concrete can result in adequate compressive strengths, there are still many questions on how the material will perform in other structural capacities or in aggressive environments. In our work, we are examining their impact on both the structural capacity of new construction and the long-term durability of that concrete.”

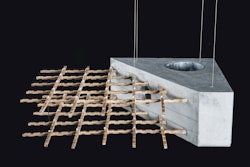

His team recently started work on some testing that is examining the bond strength of the reinforcing steel when used in concrete materials. The results from this research will help the NJIT team understand if current design methodologies and assumptions (created for natural aggregate concrete) can be used for concrete made with RCA.

“More fundamentally, we are examining how concrete cracks when RCA is included in the research,” Adams says. “When concrete dries out, it can shrink and crack. Previous research completed during my Ph.D. showed that concrete made with RCA may be able to withstand more deformation without cracking than concrete made with natural aggregates. So my colleague Dr. Matthew Bandelt and myself, along with our Ph.D. students, are developing new ways to understand how concrete may behave differently when recycled aggregates are included.”

Recycled sources can also help reduce the carbon footprint of concrete as they are generally available closer to the city where construction demolition is occurring.

“By replacing some aggregates in concrete with recycled aggregates, we can help reduce the carbon footprint of concrete even further, as well as reduce the impact that quarrying natural aggregates can have on ecosystems,” Adams says

Industry Hesitation

Despite wide acceptance of recycled materials being used in the asphalt industry, the concrete side is much more hesitant for fear of the product not performing as well as virgin materials. However, Adams says those opinions are unfounded.

“There is a general feeling that recycled materials are of poor quality compared to first run materials,” he says. “This is something that persists across industries, and not just in the concrete world. Additionally, early work from the 1970s and 1980s showed that concrete made with recycled concrete aggregates showed lower strengths than concrete made with natural aggregates, and this research has persisted in the minds of design engineers. However, advances in concrete mixture design technology and chemicals that help keep concrete fluid without increasing the water content have shown that concrete made with RCA can have adequate compressive strengths.”

Despite this, there are still many questions about the long-term durability of the material, and how concrete made with the material may act during an extreme event, such as an earthquake or hurricane. Adams says these are questions that can be answered with further research, which is what his team wants to do.

“In the case of recycled concrete aggregates, we don't have a lot of examples of their use in the field yet, as engineers have been reluctant to employ them despite research from around the world that supports their use, particularly in pavement applications,” Adams says. “But in many cases, we're seeing that concrete made with recycled materials lasts just as long if not longer than concrete made with 100% virgin materials. New research is starting to come out that is examining some pavements and structures that were built and have been in use for a number of years showing that the materials have performed well. The time to do this research is now, though, not in 10 or 20 years when natural aggregates become an even more scarce resource in parts of the country.”

This is why research of these new alternative materials is important in the construction industry. Failures of infrastructure can mean unsafe roads, and result in significant expenses in repairing or replacing failed infrastructure.

“Despite this, it is important that we reduce our carbon footprint and make our built environment as sustainable as we can. Therefore, it is important to support this research now so that we can reduce our carbon footprint as quickly as possible and build a more sustainable future. The research we perform at New Jersey Institute of Technology helps us understand how we can better create concrete mixtures to be more sustainable, more durable, and more resilient.”