Big part of New England’s history is written in stone and red-brick facades overlooking century-old neighborhoods. Trends bringing people and businesses back to historic urban centers are forcing developers and city managers to find ways to deliver modern conveniences wrapped in historic architecture.

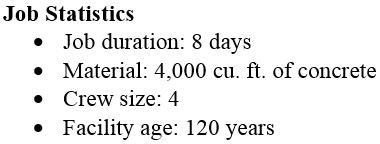

Faced with a full-scale interior demolition on a tight timeline, ADEP partnered with Brokk to provide a robotic solution to a nettling development. ADEP needed to remove a concrete pool in the basement of a 120-year-old YMCA facility in Beverly, Massachusetts. With a Brokk 200, ADEP was able to reduce crew size in the confined space while increasing productivity 50% over alternative methods, allowing them to proceed to subsequent phases quickly for an on-time project delivery.

A new approach

ADEP Group – short for American Demolition Environmental Professionals – is a demolition and remediation contractor founded less than 10 years ago. President/Owner Kelvin Severino recognized a need in the local market for a professional, organized and experienced renovation/rehabilitation response.

“New England has a rich architectural history – many buildings from the late 1800s and early 1900s are still in use,” Severino says. “They were well-built. But contractors have learned a lot over the years, and some of the materials used aren’t considered safe anymore, like asbestos and lead paint. New England developers like to make use of the rich history and attributes that these historic buildings have, so renovation and restoration have become very popular. Usually this involves a full interior demolition then rebuilding within the shell of the existing structure.”

Unfortunately, with this process, clients are often forced to hire multiple firms since most contractors offer remediation or demolition services, not both. To ADEP, this adds unnecessary complexity to projects. So, by cultivating crews with extensive experience in both industries, ADEP was able to provide turnkey solutions in environmental remediation and demolition for customers in Massachusetts, New Hampshire, Maine, Rhode Island, Connecticut and New York.

“We saw what everyone else was doing, and we knew we could offer clients more,” Severino says. “We’re here to challenge the status quo and go above and beyond what people have come to expect from the industry.”

To do that, ADEP looks for innovative solutions that allow them to provide quality results on time and within the budget.

“Safety and efficiency are primary factors in our continued growth,” Severino says. “We’re always evaluating ways to streamline our process and increase safety, which is an integral part of our culture. The demolition side of our operation was seeing steady growth, so robotic demolition was something that was on our radar. We just needed the right job to justify making the leap.”

Taking the plunge

When the Cabot Street YMCA project came up, ADEP realized it was the perfect opportunity to add a Brokk demolition robot to their fleet. The project was part of a $22 million dollar renovation aimed at creating 67 studio-like apartments for low-income residents and those with developmental disabilities. ADEP needed to completely gut the interior of the building – including removal of a concrete pool, tucked away in a 1,300-sq.-ft. room in the historic building’s basement.

“Our operator had a good grasp on the machine’s capabilities within an hour and was able to get his certification in just a few days. After a week, it was like he’d been using the Brokk for years.”ADEP Group

“Our operator had a good grasp on the machine’s capabilities within an hour and was able to get his certification in just a few days. After a week, it was like he’d been using the Brokk for years.”ADEP Group

No matter how ADEP looked at it, traditional methods couldn’t tick all the boxes for safe, efficient demolition. The only equipment small enough to access the job site was the company’s Volvo ECR28 mini excavator, which wouldn’t be enough to handle 4,000 cu. ft. of concrete within the time frame. Larger crews with hand-held equipment were another option, but filling the small room with 10 to 12 employees during a pandemic risked crew safety and job site shutdown. Not to mention ADEP estimated this method would take at least two weeks for demolition and at least one additional week for material removal. Management knew robotic demolition could provide the power and precision they needed.

“It was the perfect Brokk job – confined space, limited access, the need for lots of power in a small package,” Severino says. “Only, we didn’t have a Brokk yet.”

ADEP reached out to Brokk and Bob McCabe, the company’s field applications specialist and regional manager in the Northeast, who has more than 45 years of industry experience and has worked daily with Brokk robots for 35 years. Together they assessed the project requirements and concluded a Brokk 200 was the right tool for the current job – and a fit with ADEP’s growth goals. 2.1-ton machine pairs with a 650-lb. BHB 305 hydraulic breaker to deliver 450 ft.-lb. per blow. Within 48 hours, the robot, McCabe and Matt Lyons, Brokk training and application specialist, were on-site to provide hands-on training to the ADEP team.

“From initial contact to delivery, we were surprised how fast things went,” Severino says. “Owning a Brokk had been a dream for a while, and all of a sudden it was a bright-yellow reality. Working with Bob and Matt, our operator had a good grasp on the machine’s capabilities within an hour and was able to get his certification in just a few days. After a week, it was like he’d been using the Brokk for years.”

A powerful partner

With their operator trained, ADEP was ready to begin demolition. The Brokk robot and mini excavator were lowered into the basement with a boom truck. Each machine had a dedicated operator as well as six additional crew assigned to the asbestos abatement of flooring throughout the building and selective demolition of the gym. To mitigate dust, ADEP used a combination of fans, water and a negative air machine.

The power was impressive.

“We knew the Brokk had an excellent power-to-weight ratio, but when we saw it on the job, it was still incredible,” Severino says. “It cut through the concrete like butter, which was good since the concrete ended up being 36-in. deep instead of the 24 in. from initial reports. Our operator was able to power through while maintaining pinpoint accuracy to work around footings and columns.”

A 7-by-11-ft. breach in an exterior wall provided easy access for material removal. Once the Brokk broke apart the concrete, the mini excavator passed it through the hole to a Volvo 250 DL excavator positioned outside.

ADEP completed demolition in just eight days with a crew of four – well ahead of schedule and 25% under their original budget. Severino estimates the Brokk saved 456 hours of labor on the job. Additionally, there were no complaints from tenants or neighbors.

Breaking concrete, not the bank

With work on the Cabot Street YMCA complete, ADEP is keeping its Brokk busy on other jobsites to maximize ROI.

“Cost was really the biggest hurdle to jumping into remote-controlled demolition,” Severino says. “But now that we have the Brokk 200, it’s opened up a number of new opportunities for us.”

In addition to the BHB breaker, ADEP can use a bucket attachment with the Brokk 200 for digging tasks in tight spaces. Management is also exploring how the demolition robot can be integrated into the company’s other services, such as emergency response.

“As a company, ADEP is always looking ahead,” Severino says. “Small, strategic crews keep our employees safe, most importantly, but they also reduce labor costs and liabilities so our business can continue to grow. Brokk demolition robots, combined with our experience, professionalism and drive, give us the edge we need to keep moving forward.”