Even the most well thought out and heavily planned construction jobs can have minor things happen that simply do not go according to plan. Following some key safety rules and enforcing those rules on construction sites can help protect workers and ensure safer working conditions.

The following are some key areas contractors should routinely review to prevent any injuries from occurring on the jobsite.

Make sure to have new and working equipment

It is self-evident that proper equipment and work practices are a must in ensuring safety. This includes safety harnesses, hard hats and that any machinery used is well kept and reliable. Equipment such as cranes and scaffolding should be inspected annually to make certain they are operating properly, and wearable equipment such as hard hats and vests should be replaced if they are damaged.

Scaffolding

Scaffolding must be inspected regularly to test rigidity and its ability to carry and support the intended weight. When utilized, the scaffolding needs to be placed on a solid and even foundation to prevent displacement and should be at least 10 feet away from overhead power lines.

5 Safety Tips When Working with Scaffolding

Assembly and disassembly should be completed by an appointed person who is knowledgeable about the correct way to do so, and parts should be inspected before being reassembled again.

Cranes

Cranes are another more serious cause for accidents if not properly inspected or properly used. Before operation, any chains, ropes and hooks should be inspected for wear and tear. The weight capacity of the crane should be known and tested before being used on the actual construction site.

Along with this, when a crane is used on the site loads should never be moved over workers. Areas of the construction site where the crane is utilized should be blocked off to prevent unauthorized access.

Forklifts

Forklift-related accidents are another cause for concern. These types of accidents account for some of the highest injury rates, with around 100,000 workers injured every year. Just like any other equipment, forklift tires and haulage equipment should be properly inspected and tested for any wear and tear.

Always drive below 5 miles per hour, and follow strict guidelines in terms of moving and stacking loads. Lastly, ensure there is an audible and visual signal for when the forklift is in reverse.

Stairways

Stairways have a great potential for causing slips and falls. Stairways should be free from obstruction or debris; spills should be quickly taken care of rather than just displaying a sign showing where the spill is.

Handrails on stairways are also necessary for additional support. When using a stairway, workers should be conscious of any other individuals who are using the stairway at the same time as them so they can avoid accidents.

Ladders

Ladders are one of the biggest culprits for fall injuries. Before using a ladder, check for any damages that include missing rungs, bent rails and cracks. Also, ensure the ladder is long enough for the task and that it is propped up correctly at an angle.

When climbing ladders, workers should always have both feet and at least one hand in contact with the ladder. Avoid using metallic ladders near any sources of electricity, especially overhead power lines.

Only work with equipment that has been tested and which is free from damage, and have frequent inspections to ensure worker safety.

How to prevent trenching accidents

Trenching accidents and deaths related to such accidents have been on the rise, but normally because the following safety precautions are not adhered to. In trenches that are deeper than 3 feet, ladders or other means of exit should be located every 20 feet in case of an emergency.

Trenching and Excavation Safety Fact Sheet

Also, all trenches should be made at varying angles, depending on the material being used. More stable materials like granite can have walls that are perpendicular to the ground. However, less stable materials like sand should have a lesser degree of angle to prevent the trench from falling into itself.

Heavy loads should always be kept at a safe distance away from trenches, and any water accumulation within trenches should be dealt with immediately to prevent damage to the foundation.

Of course, trenches should be inspected daily by a knowledgeable and competent person to decrease the likelihood of a cave-in.

Be mindful of the trenching material that is being used, and ensure workers have a means of exiting the trench quickly in case an emergency does occur.

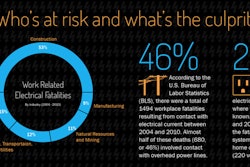

Working with electricity

Many construction sites involve having to deal with electrical circuits or avoid overhead power lines, so proper procedure when working with these elements is essential. When working on electrical circuits, make sure the power is off and that grounds are attached, especially if the circuits are visibly damaged or faulty.

Safety - Electrical Hazards on Construction Sites

Before working in a construction zone, make sure all electrical sources and power lines are identified and located. Lastly, if workers are utilizing non-insulated electrical tools, make sure the tools are grounded.

Ensure electrical sources are insulated and grounded. Workers should keep metallic objects away from such sources.

Protect your eyes

Eye protection is extremely important for any job. When work such as welding, grinding and sanding is done, workers should always wear proper eye protection to protect against any flying or detachable debris. Eye protection such as goggles should fit comfortably on the surface of the face, cover both eyes completely to prevent particles from coming in, and should be free of any damage.

Video: Construction Safety - Eye Protection

Eye-protective equipment is required to be offered to employees free of charge, and if workers have prescription lenses, eye protection can either incorporate the prescription or can be worn over the corrective lenses. Employers should always ensure the correct eye protection is being used and that it is effective.

Final thoughts

Workers should all be instructed on proper work guidelines to ensure smooth workflow, while also being provided with the appropriate safety equipment. Specific individuals should be utilized in supervising the work and ensuring guidelines are being adhered to. Equipment and tools should be inspected daily, both before and after work is completed, to reduce the chance of injuries caused by faulty equipment.

Employers should also be open to listening to the concerns of their workers in times when and if an injury does occur. Following the proper health and safety practices, as well as active communication between the employer and the employee, is essential in preventing construction-related accidents.

Jim Shaw is the content manager at Digital-2000, a company passionate about the development and implementation of safety education tools for business and industry. Jim loves helping people and being in the businesses of utilizing video based interventions in order to achieve goals and maximize results.

![[VIDEO] Construction Safety 101 - Never Assume Electrical Safety](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/05/default.5745ecf3721c4.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)

![[VIDEO] Electrical Safety Awareness for Non-Electrical Workers](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/05/default.5745eb2f97051.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)

![[VIDEO] Personal Protective Equipment Basics - Eye and Face Protection](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2015/10/default.561e6f3d7541f.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)