Concrete coring and drilling contractors are adopting new technologies that make their day-to-day job easier and safer. A popular and effective solution is the ground-penetrating radar (GPR) that is used to locate rebars, tendons, post-tension cables, and other targets inside the concrete. Using GPR not only makes the job easier but also adds value to the portfolio of services offered.

Giving your customer the option to choose between a plethora of methods is a huge advantage.

How GPR Works

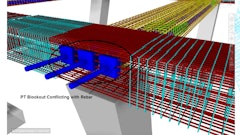

Most popular uses of GPR in concrete are the non-destructive testing and mapping of objects inside the concrete, such as rebars, pipes, ducts, cables, etc.—as well as infrastructure assessment for bridges, roads, and buildings.

GPR is a compact device that scans the subsurface in a non-destructive way. It can penetrate the surface from a few centimeters down, to tens or hundreds of meters, based on soil conditions and antenna characteristics. For concrete, we typically use antennas in the range of GHz for better horizontal resolution.

GPR emits electromagnetic (EM) waves to the subsurface and calculates the time these waves need to travel through the various subsurface material and get back to the GPR receiver. This two-way travel time, along with a few other parameters such as the dielectric, provides the user an estimate of the target depth.

GPR is an extremely useful tool in a variety of applications. Most popular uses of GPR in concrete are the non-destructive testing and mapping of objects inside the concrete, such as rebars, pipes, ducts, cables, etc.—as well as infrastructure assessment for bridges, roads, and buildings. GPR users can also map live electrical cables and see down to the bottom of the slab.

Currently, two different GPR devices exist in the market: the pulsed systems and the stepped frequency GPR. Pulsed systems send tiny pulses of EM wave down to the subsurface during periodic intervals, while the stepped frequency devices are continuously sending parcels of wave at different frequencies at the same time. In the past, due to computing limitations, pulsed systems were the main choice in the market. Despite their popularity, they have several drawbacks, like the frequency dilemma. Pulsed systems are limited by the main frequency of the antenna and thus they have specific limitations in terms of depth and resolution. However, we are seeing a switch to the stepped frequency because due to now having the necessary computing power.

Stepped Frequency GPR

Stepped frequency is gaining popularity because, with a single device you can sweep through the complete frequency spectrum—from low-to-high frequencies, achieving superb depth clarity and resolution of even small objects at the same time.

Stepped frequency devices use an ultrawide bandwidth to cover your needs in both depth penetration and horizontal resolution. Typically, in pulse systems a lower frequency does travel deeper into the concrete, but the resolution becomes worse. Specialized technologies are available that get to depth but without compromising the resolution of the target.Screening Eagle Technologies

Stepped frequency devices use an ultrawide bandwidth to cover your needs in both depth penetration and horizontal resolution. Typically, in pulse systems a lower frequency does travel deeper into the concrete, but the resolution becomes worse. Specialized technologies are available that get to depth but without compromising the resolution of the target.Screening Eagle Technologies

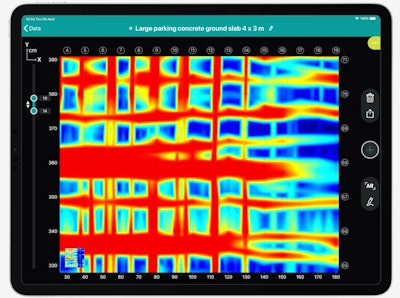

Scanning data is collected in two ways, either in 2D, which means that you collect independent line scans over the concrete surface, or in 3D, using an area scan over a pre-configured grid. Line scanning is performed by moving the GPR antenna across the surface and this results in targets on your screen.

Depending on the direction of your antenna in relation to these targets, you either get linear targets or hyperbolas that correspond to subsurface targets. Based on their amplitude, reflection type, and other characteristics, you can define the depth of the target, whether this is metallic or not, and see whether the target is empty or filled with liquid. With advanced algorithms, you can see the deterioration of the rebars and also define whether you have voids inside the concrete.

A 2D GPR profile showing a series of perpendicular targets (hyperbolas) to the movement of the GPR. This shows a real scan from the Las Vegas Convention Center - most likely rebar within the concrete floor.Screening Eagle Technologies

A 2D GPR profile showing a series of perpendicular targets (hyperbolas) to the movement of the GPR. This shows a real scan from the Las Vegas Convention Center - most likely rebar within the concrete floor.Screening Eagle Technologies

X-ray vision into Concrete

3D data collection on the other hand takes more time but you get clear, tomographic views of the subsurface. It is like an X-ray but without the need of having two side access to the target or any other inconveniences that the X-ray comes with. You can collect area data (3D) by defining a grid over concrete and select the spacing between the lines. Typically, a denser grid gives you higher resolution data while sparser one gives you worse resolution, but you spend less time on the field. Using technology, contractors can visualize 3D data with augmented reality, giving a clear view of what is inside the concrete.

3D picture of the rebar within a large parking concrete ground slab.Screening Eagle Technologies

3D picture of the rebar within a large parking concrete ground slab.Screening Eagle Technologies

Can GPR Find All Targets?

GPR can detect metallic and non-metallic targets below the surface. However, certain limitations exist, like the depth to target limitation. The rule of thumb is that GPR can detect almost any target if it is at least one inch (2.54 cm) in diameter and is buried at one foot (0.30 m) or shallower. For example, it may be impossible for GPR to locate a 3-in. (7.6 cm) plastic pipe at a 6-ft. (1.82 m) depth. Metallic targets are doing better with this rule.

A 3D representation of thick concrete wall with four rebar layers.Screening Eagle Technologies

A 3D representation of thick concrete wall with four rebar layers.Screening Eagle Technologies

Does GPR Calculate the Diameter of a Rebar?

GPR is not the ideal tool to calculate the rebar size. There is a technique where you can get approximate values for the rebar size by measuring the depth to the rebar from both in line and cross line data and the difference will give an approximate diameter. There are more accurate and easier instruments to detect the rebar size and cover which can be used in combination with GPR for a holistic approach to your concrete investigations.

About the author

Dr. Michael Arvanitis holds a bachelor’s in mathematics, a PhD in Geophysics and a post doc in GPR. For the last twenty years, he is actively working with GPR from different positions including sales, marketing, strategy and research and development. He currently works as the Head of Global Strategy for GPR for Screening Eagle Technologies.