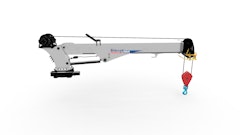

Charles Blalock & Sons of Sevierville, TN, were awarded contract for a portion of a multi-phase $71 million contract to realign and improve 1.69 miles of SR115/Alcoa Hwy south of downtown Knoxville, TN. One stretch of the new road requires retaining walls be 65 feet tall. In order to handle the steep and narrow access roads at the top of the hillside, Blalock & Sons purchased a 50-ton TCC-500 telescopic crawler crane.

One stretch of the new road requires retaining walls be 65 ft. tall. In order to handle the steep and narrow access roads at the top of the hillside, Blalock & Sons purchased a 50-ton TCC-500 telescopic crawler crane.

One stretch of the new road requires retaining walls be 65 ft. tall. In order to handle the steep and narrow access roads at the top of the hillside, Blalock & Sons purchased a 50-ton TCC-500 telescopic crawler crane.

The project is scheduled to be completed by November 2019 with the most amount of time reserved for construction of retaining walls.

The project is scheduled to be completed by November 2019 with the most amount of time reserved for construction of retaining walls.

“Right out of the gate it had to climb to the top of the hill, which was a 30% grade. The book said it could go up to 40% so we were confident that it would make it up and it did just fine,” says Project Superintendent for Charles Blalock & Sons, Tim Payne.

“We rented the TCC-500 in Chattanooga on a similar project and liked the way it handled the grades on that US 27 project,” says Project Superintendent Tim Payne. “When we got this bid, Blalock & Sons decided to go ahead and buy it from the distributor (Atlantic & Southern).”

Aside from the steep terrain, the other time consuming aspect of the project is the granite formation being drilled through in order to build a soldier pile wall for shoring up 112-foot-deep soldier pile. Once a hole is drilled out, the TCC-500 suspends a 15,000-pound H-beam in the hole until it can be leveled. Once it is, the hole is pumped with concrete to be held in place.

Workers pour concrete into a drilled hole.

Workers pour concrete into a drilled hole.

“We’ve really liked having the TCC-500 on this project, it feathers in with the controls nicely whenever we’re handing off cans or whatever we need to pick,” said Payne.

The project is scheduled to be completed by November 2019 with the most amount of time reserved for construction of retaining walls.