To help equipment owners and managers prepare for the the upcoming transition to PC-11 engine oil categories Chevron offers a weekly "ask an expert" Q&A series. Many of the questions revolve around fuel economy and how the new oils affect oxidation and component life.

Here is what the Chevron experts have said.

What role does low viscosity PC-11 oils play in regards to fuel economy?

While high film thickness oils have been used for a number of years, lower viscosity has become a bigger focus given the need for enhanced fuel economy. The fuel economy improvement that can be expected from using lower viscosity oils depends on the engine type and duty cycle, and with the oil that is selected.

Compared to conventional API CJ-4 SAE 15W-40 oils, studies have shown that fuel economy improvements of 1.5% or more can be achieved when oils like those that will be licensed as API FA-4 are used.

What are the fuel efficiency targets for the different sizes and weights of on-road vehicles? What are the expected improvements in carbon emission reduction?

The greenhouse gas and fuel economy standards that were jointly issued by the U.S. Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) in 2011 are quite complex, but in essence they mandate reduction of carbon dioxide (CO2) emissions and fuel consumption in medium and heavy-duty vehicles. The exact emissions and fuel economy standards vary by model year and vehicle class.

In general, the target is up to 20% improvement compared to baseline 2010 model year vehicles. In fact, even tougher standards have already been proposed that will force even better fuel economy over the next 10 years.

In addition to fuel-efficiency, how are these new oils protecting the engine from oxidation?

This is a great question because it highlights a common misconception about the new engine oil categories. While the new specifications were certainly motivated by the need to introduce new more efficient engines and vehicles, there will also be a significant performance upgrade with the new oils in addition to the new lower viscosity grades.

When engine manufacturers requested this new category back in 2011, they were clear that the new oils needed to be significantly more resistant to oxidation. That is to say they need to stand up to higher temperatures, for longer periods of time without breaking down. So, as these new products have been developed, particular attention has been given to making sure that the right combination of high quality base oils and advanced additive technology are brought together to answer the needs of the most stringent heavy-duty motor oil specification ever developed.

How has oxidation resistance been improved in PC-11 oils?

When the PC-11 category was first proposed by OEMs back in 2011, it was clear that engine makers were looking for new motor oils with significantly improved protection against oil breakdown at elevated temperature (oxidation). This has forced oil formulators to utilize new additives in combination with more stable base oils to deliver the improved performance.

How is component life and/or performance affected with the use of PC-11 formulated oil on new engines?

PC-11 oils will be formulated to be more resistant to oxidation — this means that they can stand up to elevated temperature for longer periods of time without “breaking down.” This is something that engine makers identified as a priority because of the greater demands that new engines are placing on the oil, as well as the desire for longer oil change intervals. The use of oils not meeting these new requirements may compromise the end users’ ability to achieve maximum OEM-published oil drain intervals.

Using the new oils also ensures that the operator is taking advantage of the latest advancements in wear protection and viscosity control. Obviously, picking the right viscosity grade is important — not only considering operating climate, but also potential for improved fuel economy.

What tradeoffs have been made to achieve better fuel economy and reduced emissions with PC-11 oils?

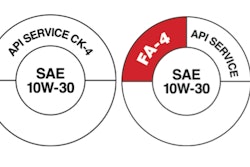

Oil formulation is certainly a balancing act. In fact, the API CK-4 and FA-4 specifications each require that nine engine tests, each with unique performance requirements, and several bench tests be passed to demonstrate robustness to wear, deposit formation and premature oil breakdown. In addition, engine oils must flow at low temperatures while still providing adequate protection when they are passing through the hottest parts of the engine.

Of course, the needs for emission control system protection put constraints on the types of components (and how much of these components) that can be used in the finished product. None of this would be possible without access to the highest quality lubricant base oils and advanced additive technologies working together.