Selecting the best dewatering solution for your customers' needs requires experience and an understanding of the physics involved. For optimum performance and equipment life, it's important to choose the correct type and size of pump, as well as set it up for the application.

Many parameters influence an effective pumping system. You need to understand the required flow, pressure, solids size, suction lift, altitude, specific gravity, viscosity, temperature and fluid type.

If your customer is pumping water, use suction lift and discharge elevations as a bare minimum estimate. Then account for any losses in the system. The TDH (Total Dynamic Head) is then created by adding friction losses from the distance pumped, as well as all valves, fittings and equipment downstream which have resistance to the suction and discharge.

The longer the discharge run of the hose, the more the friction loss. Likewise, the more friction loss there is, the less flow. Minimize how much friction loss there is through the hose. Keep in mind that all pumps are limited to a maximum suction lift of about 28 feet.

Solids content can actually dictate pump type. Centrifugal pumps have limitations of the size and hardness of solids. Diaphragm, vane, gear, lobe, progressive cavity and submersible pumps all have applications that are best suited to their design and the work to be performed.

Centrifugal pumps are effective up to a maximum of 4% to 5% solids at best. Anything higher will require a positive-displacement pump, such as a diaphragm pump. As such, it's important to consult the manufacturer's specifications for solids-handling diameter.

It's a good idea to use a suction screen that is slightly smaller than the solids-handling diameter to protect the pump from large debris. Also consider the materials used in the wear parts. The higher the concentration and diameter of a solid, and the greater its hardness, the greater the potential for failure of the wear parts (impeller, wear plates, seals, volute, etc.).

Value of wet prime

Trash pumps come in several variations with different inlet sizes, solids-handling capability and efficiencies. Wet-prime trash pumps are one of the easiest to use and maintain as they have fewer components than other pumps - basically a pump and a motor/engine. Wet-prime pumps require the pump cavity to be filled for the first time, then will "self prime" as long as there is water above the eye of the impeller. To prevent the pump casing water from siphoning the water out when the pump is shut down, there is a check valve on the suction side.

Fewer moving parts can be a big advantage. Depending on how it is designed, a wet-prime pump can last 20 or 30 years with regular maintenance. The difference in the pump end is the wet-prime pump has a large volute to hold a large volume of water.

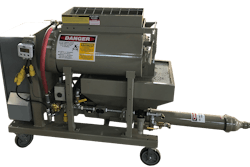

The benefits of a wet-priming trash pump are portability, independence from a designated power source, ability to be placed right at the water's edge and relatively inexpensive purchase price and operating cost. Disadvantages include the need to manually prime, inability to control speed and limited fuel capacity that demands more frequent monitoring and refueling.

Wet-prime pumps are a little more bulky, and priming is affected by internal pump wear. Dry-prime pumps, on the other hand, are smaller in physical size, and priming is unaffected by internal wear. There are more moving parts to maintain, however.

Wet-prime models have operational limitations, as well. Wet-priming trash pumps are best suited for applications with a relatively low sump. Specifically, applications with less than 200 feet of discharge - not pumping more than 350 gpm - are the most common. Yet, their impeller design makes them a good solution for jobs where solids are present. They are successful in applications including trash-laden water found in construction applications, stream and pond dewatering and septic tanks and manholes. They work best where there is an abundance of liquid, when the pump running constantly, or if the unit has an automatic float control for automatic on/off operation.

The best conditions for wet-priming pumps are open pit and sumping applications, where the suction lift is less than 25 feet and where priming time is not as critical. Wet self-priming pumps normally take longer to prime, depending upon suction lift and length of suction hose/pipe.

They also can be used for bypass pumping when there is sufficient retention time to allow for the pump to prime. While the wet-prime pump can handle some air intrusion on the suction side, if there is a significant intrusion of air, it will lose its prime and will need to re-prime itself. So for a good period of time, the pump is not pumping.

In addition, while wet-prime pumps can range up to 12 inches, this says little of their capacity. For the most part, wet self-priming pumps are of a lesser capacity due to their design limitation than their cousins, the dry-prime pump.

When dry is best

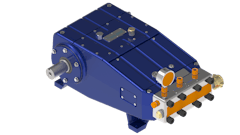

Dry-prime pumps prime without the need to add fluid. Prime is maintained via a priming device, which is normally either a vacuum unit, diaphragm or compressor. The priming process is achieved by the use of an integral compressor, which creates a full vacuum through a venturi eductor. This is suited for nearly all dewatering and transfer applications that require high and rapid static suction lift.

Rapid priming coupled with higher volumes results in greater efficiency over wet-priming units. A dry-prime pump with vacuum assist can increase performance by 20 percent over a wet-prime pump, but the initial cost is probably 40 percent more. "The increased cost is more than offset over time by the fuel cost savings in running a more efficient unit," says Mike Grant with Tsurumi. "Saving money and being able to do more with your equipment are necessary selling features in today’s marketplace."

It should be noted that seals in pumps that often run dry can overheat and fail. To combat this problem, some mechanical shaft seals run in an oil bath, which dissipates heat through the pump casing and allows the pump to run dry indefinitely. "This provides more reliable operation, frees operators from closely monitoring the pumps, and reduces maintenance costs," says Kristen Gurick at Xylem Dewatering Solutions.

A dry-prime pump will nearly always outperform a wet-prime pump due to its design. Generally, dry-prime pumps will incorporate non-clog impellers, which are often more efficient than the open trash impeller used in the wet prime.

"An open impeller design means pumps can handle solids up to 5 inches in diameter, and can be used in a wider range of applications, from water and wastewater to drilling muds and industrial fluids," Gurick points out.

The non-clog design allows for larger sizing, allowing the pumping capacity so you can get a much bigger dry prime. Yet, the term "non-clog" can be misleading. The impeller will clog if a large enough solid is pulled into the pump, i.e., plastic bottles, towels, bricks, etc.

Due to their ability to handle large volumes of air in the suction, dry-prime models are often used in applications where they might experience dry running or see intermittent flow, such as sewer bypass or construction sites where the unit must constantly work to keep the area completely dry. Large air volumes can occur from suction vortexing, turbulence or low fluid levels. The prime-assist dry-prime will pick up suction prime without any need of an operator filling the pump with fluid.

Dry-prime trash pumps can use automatic controls to start and stop pumping based on flow levels. The obvious advantages include extended hours of service, increased capacity (volume), decreased dewatering time, higher lifts, independent operation, a broader range of liquids pumped, more durable wear parts and larger solids-handling capabilities.

Grant adds, "Plus, there's the ability to prime the pump in applications or conditions where self priming is not possible or where wet priming of the pumps is difficult."

A solution for thick fluids

Certain situations require positive-displacement pumps, such as a diaphragm pump. Diaphragm pumps are available in a wide variety of materials and elastomers. Advantages include few moving parts and simple operation.

Diaphragm pumps will handle very thick materials and create full discharge pressures without regard for any certain position on the performance operating curve. Traditionally air driven, but also engine and electric fitted, they are generally of low volumes.

Diaphragm pumps are particularly suited for low-flow applications with muddy water, but they can only handle low flow and low head (pressure). The advantages are they can run dry, they are relatively inexpensive, they are pretty portable and they are relatively small.

Because they can handle both equally, it generally doesn't make a difference to the pumps if they are moving air or water. The major disadvantage is that diaphragm pumps require a lot of maintenance. The back and forth action on the diaphragm tends to wear it and other components out quickly.

It's difficult to say how long a diaphragm will last before needing to be replaced, however, it would not be uncommon to change them monthly on continual use. Diaphragm pumps are not ideal for liquids containing abrasive solids, as they're susceptible to a relatively short diaphragm life, depending on the product being pumped.

Go with the flow

To ensure proper pump selection, it's important to know the answer to some simple questions. These include the lowest and the highest level of the water to be pumped, the quantity of flow required, the distance the water will be pumped and where it's going to be discharged.

The flow rate can be calculated based on the time frame you have to pump out a given area. Consider any obstructions to the pump layout. From there, you should be able to ballpark and pick out a correct application for the customer. It's really a pretty simple step-by-step process that, with the correct information, ensures the right pump can be chosen nine times out of 10.

It's a good idea to pick a minimum of two pumps to handle the peak flow. This avoids putting the entire bypass on one machine, and will avoid short cycling of a large pump. This is before adding a standby or backup pump to the selection. In addition, all pumps on the job should be the same size to ensure redundancy.

All pump manufacturers show curves that indicate the hydraulic potential of a pump. Keep in mind that hydraulic performance can be greatly affected (up to 50%) by the suction and discharge length associated with the application. As a general rule, the elevation needed for the application should be half or below half of the pump shutoff elevation. This rule accounts for hose/pipe friction loss.

Height also affects the pressure required by the pump. Mostly, the pressure required is found by adding the vertical heights needed and the friction losses through the pipes.

Given the complexities involved, don't hesitate to seek experienced assistance. Pump suppliers can be a vital resource to help you quickly assess project requirements. Some suppliers offer a pump application checklist that the customer fills out, helping the pump supplier to assist with the best selection for the job.

For more complex dewatering tasks, your customer might need an expert on site to size up the situation. It's always important to seek out qualified advice. The best place to get advice is from firms that routinely use pumps in everyday operations and have the background in pump systems and applications. There is no better tool than experience.