When Bobcat introduced the Tier 4 versions of its 500 frame-size loaders in November, the company quietly rolled out a new Bobcat engine that requires no diesel particulate filter to satisfy U.S. EPA’s Tier 4 Final emissions regulations. In a press conference last week, the company shared more detail on how these engines – in displacements up to 3.4 liters – certify to Tier 4 without a DPF.

Bobcat Eliminates the DPF on Tier 4 500 Frame-size Loaders

All of the Doosan-built engines use cooled exhaust gas recirculation, electronically controlled high-pressure common-rail fuel injection and a diesel oxidation catalyst. With no DPF the engines eliminate the need to burn off accumulated particulate in what’s called regeneration – a step that on other engines relies on fuel injected into the filter to burn off the excess carbon.

Heat from regeneration requires warning operators when the process is happening, and giving them an option to override the system to prevent increasing fire risk – like when operating indoors or in highly flammable environments.

The 3.4-liter Bobcat engines (to be introduced in 2015) are expected to need selective catalytic reduction to be certified Tier 4 Final. The technology requiring diesel exhaust fluid to help catalyze oxides of nitrogen out of the diesel exhaust stream has been appearing on truck engines and larger off-road engines for some time. At present, it’s considered to be a necessary step to compliance for many engines.

While Bobcat says reduced operator interaction is a benefit of its Tier 4 engines, the company is quick to point out that a key selling point should be across-the-board torque increases of from four to 12 percent. Torque is the turning force the engine is able to exert on an output shaft.

“We blind-tested customers on machines with the new engines and machines with the previous-generation engines,” says Bobcat Marketing Manager Chris Knipfer, “They overwhelmingly preferred the machines with the new engines.”

Part of Bobcat’s message about the new engines is to talk about the primacy of torque over horsepower as a measure of working power. Engines are designed to deliver peak horsepower near their rated engine speed. When the engine encounters hard resistance, it lugs down – its speed drops – and horsepower drops with it.

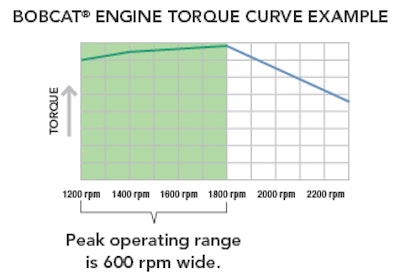

Torque, on the other hand, can be manipulated to rise quickly at low engine speeds, and the curve flattens out and stays at or near peak torque over a relatively broad range of engine speeds.

Bobcat shows and example torque curve for one of its engines that stays in the peak torque range over an engine-speed span of 600 rpm.

Combustion pressure is a key variable for matching torque to power demand, and that’s why even small engines are using high-pressure fuel injection and electronic injection control. Electronic control and multiple injection events during each combustion cycle allow the engine to vary combustion pressure.

When power demand is low, the fuel system produces lower combustion pressure to reduce noise and fuel consumption. In hard digging and other kinds of intense work, the system can dial up the pressure to deliver near-peak torque across a much broader range of engine speeds.

Bobcat says the variable nature of the system delivers more consistent machine performance over time as well. The fuel system can compensate for some combustion pressure lost to cylinder wear, so the machine continues to perform like new longer into its life.

Bobcat Engine Models

1.8-liter (intro in 2013)

- 400 Frame-Size Loaders

2.4-liter (intro in 2014)

- 500 Frame-Size Loaders

- 600 Frame-Size Loaders

- Toolcat Utility Work Machines

- E42, E45, E50 and E55 Mini Excavators

3.4-liter (intro in 2015)

- 700 Frame-Size Loaders

- 800 Frame-Size Loaders