Prior to 2000, there were primarily two types of transmissions available for medium- and heavy-duty trucks – manual and torque converter automatic. The Class 8 trucks used for long-haul applications typically relied on multi-speed manuals while the vocational truck market was split between manual transmissions and the torque converter automatic transmissions.

Right around the year 2000 a new transmission option began to gain traction - the Automated Manual Transmission (AMT). This option began as a modified version of a manual transmission that used computer-controlled shifting.

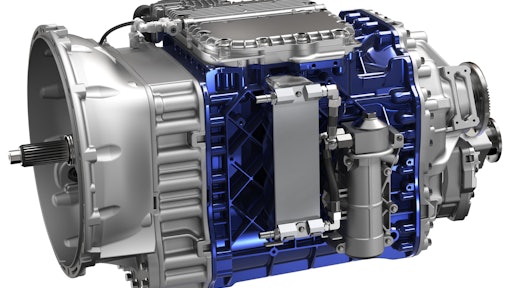

Volvo introduced its first I-Shift AMT to Europe in 2001 and subsequently brought it to the North American market in 2007. Since then, more than a million Volvo Trucks around the world have been sold with the Volvo I-Shift transmission. In 2013 the I-Shift was made a standard feature across the entire model range, resulting in a current overall order rate of 94%.

“More than 217,000 Volvo trucks have been sold with the Volvo I-Shift since its launch 15 years ago in North America, marking a significant change in a market where manual shifting was a very strong tradition,” says Johan Agebrand, director of product marketing at Volvo Trucks North America.

The AMT addressed two pain points in the trucking industry – an acute driver shortage and fuel costs. These factors are relegating the once dominant manual transmission into virtual extinction. When it comes to addressing the driver shortage, the AMT opens the profession to a larger pool of candidates that may have never been exposed to manual transmission operation. It also helps with driver retention and safety by providing fewer distractions and reducing stress.

AMTs also include intelligent controls that can perform shifts as efficiently as the best drivers, all of the time. The Volvo I-Shift uses intelligent electronics to continuously monitor grade, speed, weight and engine load, either shifting or holding a gear as needed to conserve fuel. The transmission system is fully synchronized and integrated with the rest of the truck, using information available from both the engine and the vehicle to optimize operations for different applications. Besides keeping fuel costs down, the I-Shift can also help slow driveline wear, extend transmission life, lower maintenance costs and increase vehicle uptime.

The AMTs first gained acceptance in the on-road markets. Off-road vocational trucks face a unique set of demands with PTO-powered bodies and accessories and the need to traverse soft underfoot conditions. Often heavy loads need to be started under less-than-ideal conditions. These needs were often met with vocational-focused manual transmissions or torque converter automatic transmissions.

The torque converter automatic transmissions have carved out a dominant position in specific applications. They utilize a torque converter to connect the driveline via a fluid coupling. An automatic transmission uses fluid pressure through a torque converter to transmit power through a set of planetary gears to a final drive. Due to the torque converter coupling, power to the wheels is never interrupted which is an advantage in poor underfoot conditions. Full power shifts provide quick acceleration and eliminate the need for constant shifting. As a fluid coupling device that delivers a cushion effect during the launch of a vehicle, a torque converter reduces stress on all components in the driveline and increases vehicle uptime. A torque converter provides startability, acceleration, smooth operation and maneuverability through its ability to multiply engine torque by up to 2.7 times.

The downsides of the torque converter automatic transmission versus the manual transmission were mainly the increased purchase price and, in some cases, weight.

The AMT transmissions were eventually modified to address the concerns of the vocational market and provide a third option. For instance, the Volvo I-Shift for Severe Duty features hardened gears and other hardware to help withstand frequent shifting in rugged operating environments. A Volvo I-Shift with crawler gears was introduced for applications where steep-grade startability and low-speed maneuverability are critical for maximum loads. The crawler gears option enables controlled forward and reverse travel at extremely slow speeds.

Some of the initial limitations with AMTs in specific applications, such as being pushed by pavers, has been addressed with software updates. This broadens to the scope of possible applications.

The I-Shift with crawler gears is also a good solution for heavy-haul applications that are frequent in the construction industry. The 13- or 14-speed Volvo I-Shift with crawler gears is a solution for GCW loads up to 220,000 lbs. The deep reduction of the crawler gears provides excellent startability, which reduces the need for a higher axle ratio. This allows a faster rear axle ratio to be paired with the I-Shift with crawler gears, bringing greater fuel efficiency to vocational and heavy-haul when at highway speeds by lowering cruise rpms.

With advancements in AMTs, the vocational truck market is currently witnessing a major shift. AMTs and torque converter automatics are squeezing out the manual transmission.