Vacuum excavators have come a long way from their early days as accessory tools used largely to clean up spoils generated by horizontal directional drills (HDD). Their progression to sophisticated excavators came about in large part due to contractor creativity when the HDD market went bust in the 1990s. Left with too many sidelined machines, contractors found ways to put their vacuum excavators back to work doing everything from digging postholes and cleaning drainage tubes to potholing/daylighting and damage prevention. Today, those latter tasks have grown to become the primary markets for vacuum excavation.

A vacuum excavator's ability to perform "soft" excavation gives it an advantage over other methods and machines traditionally used for locating underground utilities.

"Using air or water to cut through the soil is a lot less intrusive than using a bucket on a backhoe or mini- excavator and it's a lot less labor intensive than digging with a hand-held shovel," says Ed Savage, underground market segment manager at Vermeer. "A vacuum excavator eliminates the steel edge on either a bucket or a shovel that could potentially cut through a utility line."

Of course, all states encourage contractors to contact a One-Call service to have the utility located before digging, notes Kevin Smith, product manager – underground technology at the Ditch Witch organization. But it doesn't specify depth, and has a tolerance window of up to 2 ft. on each side of the line.

"With such a wide window, and continued congestion of our underground infrastructure, you may be working well within that window," Smith says. "By using soft excavation, a contractor can minimize his risk for damaging a utility. Eliminating just one possible hit on a utility could easily pay for a vacuum excavator considering the costs that are associated with repairing that utility."

Costs for a trailer-mounted hydroexcavation unit (about 500- to 550-gal. capacity) will run about $30,000 to $35,000, which is comparable to a mini-excavator or small backhoe-loader. "That price makes it very easy financially for a contractor to see the benefits of these machines," says Smith. "Not only can a contractor utilize them for locating and exposing utilities, but because these machines have such a wide range of applications, they find additional applications for them. For example, in a congested area where a mini-excavator or tractor-loader-backhoe can't fit, they can use a vacuum excavator for digging."

"Contractors continue to find more markets for these machines," adds Savage. "That diversity makes them a pretty good return on investment."

Big or small?

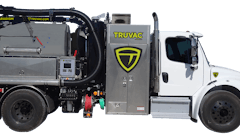

Vacuum excavators are available in a variety of sizes, from Vermeer's 40-gal. mini-skid-steer-mountable model to Vactor's 1,300-gal. truck-mounted unit.

The introduction of more compact models enhances agility for use in small spaces. "We're beginning to see more models with smaller spoils tanks," says Smith. "But that smaller size doesn't necessarily compromise performance. It admittedly limits the capacity at which these units can store spoils. But many of these smaller machines have actually increased their performance with larger engines and blowers.

"If you're locating utilities, you may only need 200 or 300 gal. of capacity because you're making 5- to 6-in.-diameter holes 3 to 4 ft. into the ground," he continues. "That just doesn't generate much in the way of spoils compared to pulling out spoils from a pit created by a directional drill."

This doesn't mean that large machines are outdated and irrelevant. It's quite the contrary, according to Tony Fuller, director of sales and marketing at Vactor. "We have seen a significant increase in the demand for larger, truck-mounted units," he says. "These units are especially advantageous in remote locations. With a smaller unit, you'll need to bring a water trailer and dump often. You can lose a considerable amount of time driving back and forth getting water and dumping spoils. When you're paid by the hour or the number of holes you dig, you won't want to spend a lot of time chasing around. With a larger unit, you can be gone all day and complete the task without returning to the office."

Advantages

of water

In addition to a number of alternatives in size, you also have a choice between high-pressure air or high-pressure water (hydroexcavation).

It is generally accepted that hydroexcavation works most efficiently in a wider range of soil conditions than a high-pressure air unit. "The highly concentrated, high-pressure stream of water is very productive in cutting through the ground," says Smith. "As you work in multiple areas, you'll likely encounter a range of soils from clay to gumbo to loam to sand. A water-based system will allow you to perform in all of those locations."

Water also acts as a natural lubricant and controls static electricity. "Anytime air moves through the soil, it creates friction, which creates static," says Deepesh Nayanar, product manager for hydroexcavation at Vactor. "With an air system, there is potential for a problem with static electricity, especially in sand because of its conductive properties. Some companies will offer anti-static lances, but it's still an issue to consider."

Hydroexcavation has the upper hand in year-round applications, which is important in northern areas where the ground typically freezes. "We would typically heat the water to about 160° F to cut through frozen ground and also in hard clay," says Nayanar. "With air, you just can't do that."

Water also prevents the sandblasting effect of air to promote a clean, relatively dust-free working environment.

Benefits of air

Air is not without its proponents and its preferred applications.

"The biggest benefit of an air system is that you have dry spoil to put back into the pothole," says Savage. "In many cities and municipalities, there are restrictions for using wet spoils. That means the slurry created with a water system will have to be hauled away and dry spoils brought back."

That's because the property of the soil is changed with the introduction of water, says Nayanar. "You change the compaction ratio so wet soil isn't reusable until it's dry. You can't just dump wet spoils back into the hole."

Air also has the advantage in that it's always available. "You don't have to bring air with you to the jobsite," notes Fuller.

Greater diversity

For both air- and water-based units, noise reduction has been furthered through the addition of soundproofing and silencers. This makes them much more conducive for working in residential neighborhoods, furthering their diversity.

"Although the vacuum excavator market basically came to a halt with the directional drill industry, it's become a much more stable market," says Savage. "What's kept it that way is the diversity of the vacuum and contractors finding other uses for them."