Driver skill level, the operating environment, and life-cycle operating costs help determine the correct transmission type for your particular application. In the off-road environment, it is important to protect the driveline from shock loads. The driver is often the weak link. Shock loads from improper shifting, starting out in too high of a gear, spinning the wheels or difficult soil conditions can lead to the most expensive failures. This includes damage to the input shaft, main shaft and gears. Severe shock loads can even crack teeth or tear teeth out of the gears, not to mention the potential damage to driveshafts and rear ends.

But clutch failure ranks among the most common problems. “Major failures of gears or shafts can occur with severe abuse,” says Peter Schimunek, marketing segment manager, Western Star. “Driver training is the best solution.”

When properly operated and maintained, modern transmissions have proven very reliable. “Overall, transmissions are very robust,” says Stu Russoli, Mack highway and powertrain products marketing manager. “Failures can be caused by mis-spec’ing for the application, driver abuse or a lack of maintenance. To avoid such issues, proper maintenance and driver education on how to use the transmission are critical.”

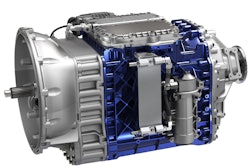

Transmission choice helps mitigate potential abuse from inexperienced drivers. There are currently three types of commonly available transmissions for Class 6 to 8 trucks: manual, automated manual (AMT) and automatic. For many years, the simplicity, reliability and low acquisition cost meant the manual transmissions dominated the market. But as skilled drivers have become scarce and electronic engines allow better communication with the transmissions, there has been an ongoing shift from manual transmissions to automatic and automated manual transmissions. Several new AMT transmission choices in the vocational marketplace are providing popular alternatives to the manual transmission.

However, there is often confusion in the terminology “automatic” and “automated.” These terms cannot be used interchangeably. While AMTs and automatic transmissions both automate the shifting process for the driver and allow the driver to concentrate on the task at hand, they are very distinct products that accomplish this task using very different methods.

An AMT, as its name implies, is an automated version of a standard mechanical transmission in which an on-board computer communicates with solenoids to electronically operate the clutch and shifter. Electronic sensors, processors and actuators do the shifting to match travel speed with the load and job application.

There are a handful of AMTs available in the medium- and heavy-duty truck markets from companies such as Eaton, Mack, Volvo and Daimler Trucks.

Automatic transmissions, on the other hand, utilize a torque converter to connect the driveline via a fluid coupling. An automatic transmission uses fluid pressure through a torque converter to transmit power through a set of planetary gears to a final drive. Due to the torque converter coupling, power to the wheels is never interrupted. Full power shifts provide quick acceleration and eliminate the need for constant shifting. As a fluid coupling device that delivers a cushion effect during the launch of a vehicle, a torque converter reduces stress on all components in the driveline and increases vehicle uptime. Allison is the major supplier of automatic transmissions and Caterpillar offers its own CX line of transmissions in its CT series vocational trucks.

Compare Pros and Cons

Many factors can influence which type of transmission is the best choice for your operation, and it pays to consult your local dealer. Technology is constantly evolving and yesterday’s best solution may not be right for tomorrow.

While manual transmissions have stood the test of time and offer the greatest simplicity and lowest acquisition cost, they require the most skill to operate. Fuel efficiency and reliability are directly related to driver skill. With the evolution in truck electronics and the ability of the engine to communicate with the transmission, only the best operators have a chance of coming close to the fuel efficiency of an automated or automatic transmission. But if you have access to skilled drivers, the manual transmission is still a proven, cost-effective solution.

The AMT combines a traditional clutch-actuated manual gearbox with a computer-controller shift actuator and clutch. Automated control of the clutch improves shift quality and leads to longer clutch life.

“AMTs will provide longer clutch life and less driveline wear over the life of the vehicle,” says Schimunek.

Benefits of automated transmissions include lower fuel costs from improved fuel efficiency, reduced wear and tear on the transmission and extended brake life.

“AMTs offer several advantages over conventional automatic transmissions, including lower price, lighter weight and reduced maintenance time and costs,” says Russoli. “An AMT does, however, use a clutch, and clutches eventually wear out. The cost of replacing an AMT clutch is still far less that the price difference between an AMT and conventional automatic.”

The benefits of the AMT has made it a popular choice. ‘These benefits include better fuel efficiency, lighter weight and less expense,” says Schimunek. “The downsides are the clutch activation is not as smooth [as the automatic] in very slow or stop and go applications; clutch maintenance; and a loss of momentum during the shift.”

There is a strong movement in the industry toward AMTs. Mack Trucks recently made its mDrive HD AMT transmission standard on its Granite vocational trucks. “In general, most vocational applications are well-suited for an AMT,” says Russoli. “When in doubt, we like to look at each application on a case-by-case basis. We consider several factors, including startability and gradeability calculations that take into account the GVW/GCW of the vehicle and the grades the truck will see. Fuel efficiency is also an important factor, as AMTs offer up to a 5% to 10% fuel efficiency advantage over conventional automatics.”

Much of this may be attributed to the torque converter when it is not locked up. “The Eaton UltraShift PLUS has been shown to produce better fuel economy due to the elimination of torque converter losses,” says Ryan Trzybinski, Eaton. “Torque converter losses come from operation before lockup and the operation of a hydraulic pump, two events that are not required with an UltraShift PLUS transmission.”

Russoli adds, “Another key factor we consider is which low-end and high-end gears are needed for the specific application. In other words, we look to see if the overall reduction of the transmission’s low gear and rear axle ratio will allow the truck to idle along at the required low-end speed without using the brake. At the other end of the spectrum, we look to see if the high gear and rear axle ratio will allow for the required top speed at an appropriate engine rpm.”

Automatic transmissions have carved out a dominant position in specific applications. “Full automatic transmissions are better suited for severe stop and go applications,” says Schimunek. “They have become ‘standard’ for other applications such as plow trucks and cement mixers, as well.

“The benefits of an automatic include ease of operation; smooth, carefree driving, long life, lowest impact on driveline and the feeling of full power shifts,” he continues. “The downside include cost, weight, less fuel efficiency and expense to repair.”

The fluid coupling helps cushion shock loads and protect the powertrain, while the ability to continually supply power to the wheels without interruption is also an advantage in poor underfoot conditions. Torque converters also help to get heavy loads moving in soft soil conditions. A torque converter provides startability, acceleration, smooth operation and maneuverability through its ability to multiply engine torque by up to 2.7 times.

“The continuous power flow offered by conventional automatic transmissions is another factor that must be taken into account when spec’ing a truck,” says Russoli. “Some rare applications may require this capability. However, we’ve found that the smoothness of the shifting with the Mack mDrive HD has not brought to light any issues as far as power interruption is concerned.”

“The Eaton UltraShift PLUS AMT does have power interrupts,” explains Trzybinski. “The technology uses electric clutch actuation, allowing the system to engage and disengage at the appropriate time. An advantage of these systems is the ability to use engine braking at low speeds both in reverse and forward gears. This can dramatically reduce driver fatigue as the driver doesn’t need to use the service brake as frequently. UltraShift PLUS is also integrated with the brake system to offer hill hold technology, allowing the driver to go from the brake to the throttle while holding the truck. This can be a big advantage on grades.”

An operator with a manual transmission can actually create a shock load on a hill by letting the clutch out too rapidly.

Weight vs. Payload

Any weight saved when spec’ing a truck translates directly into increased payload capacity. And the different types of transmissions offer trade-offs in terms of weight.

“AMTs are generally lighter and less expensive than a full automatic in the same power range,” Schimunek comments.

The weight savings over automatic transmissions can be substantial. “While exact weight can vary according to power take-off (PTO) provisions, the Mack mDrive is more than 200 lbs. lighter than a conventional torque converter automatic transmission at a similarly rated torque capacity.”

In general, AMTs are slightly heavier than comparable manual transmissions. “This varies by model but automated transmissions tend to be around 300 lbs. heavier,” says Trzybinski. “The recent Fuller Advantage transmissions for both manual and automated eliminate 75 to 82 lbs. of weight, in part by removing the need for an external oil cooler.”

But the weight differences really depend on the specific transmissions being compared. In some instances, the AMT can actually weigh virtually the same as a manual transmission. “Comparing the Mack mDrive HD 12-speed AMT to a basic dual countershaft 10-speed manual would show the weights to be similar, with the mDrive HD being about 10 lbs. lighter,” says Russoli. “Comparing to a basic Mack triple countershaft 10-speed manual, the mDrive HD would be around 75 lbs. lighter.”

Be careful when comparing weights. “It’s not an apples-to-apples comparison,” says Schimunek. “Consider that the Detroit DT12 AMT is a 12-speed. A manual 10-speed is about 40 lbs. lighter, while a manual 13-speed is actually heavier.”

Calculate Life-cycle Costs

To calculate life-cycle costs, you need to account for the acquisition cost and then calculate the cost of the required maintenance over the anticipated life of the truck. Factors such as how the weight impacts payload and the estimated fuel efficiency also need to be considered.

Manual transmissions offer the lowest acquisition cost followed by AMTs. “The initial price for the mDrive HD is significantly less than a conventional, torque converter-equipped automatic transmission,” says Russoli.

No manufacturer will charge the same for a given transmission. “Cost is controlled by the OEM,” says Trzybinski. “The Eaton UltraShift PLUS is often a significant discount to the truck buyer over a torque converted transmission. This discount can range in the $4,000 to $6,000 territory.”

Routine maintenance on an AMT is similar to a manual transmission. “The maintenance on an Eaton AMT is identical to our manual product,” says Trzybinski.

“Maintenance for the Mack mDrive HD compares favorably to a manual transmission, with a key difference being no transmission oil filter on the manual,” says Russoli. “The amount of transmission oil needed in a manual is slightly lower, and the standard transmission oil change intervals are 500,000 miles for synthetic oil and 250,000 for mineral-based oils.”

He adds, “Compared to a conventional, torque converter-equipped automatic transmission, routine maintenance on the mDrive HD requires less transmission oil — just 16 quarts total — and a longer drain interval of 500,000 miles when using the recommended synthetic transmission oil. The mDrive HD also has just one transmission oil filter, which requires replacement at the same time as the transmission oil.”

Russoli cautions that service intervals for any transmission may be shortened depending upon the application. “The best advice is to follow the manufacturer’s recommendations based on the truck’s duty cycle and application,” he says.

The amount of service required by a manual or automated transmission depends on the make and model. For instance, not every manual or AMT requires a manual clutch adjustment. “Our AMT utilizes an Eaton self-adjusting clutch, which eliminates the need for a manual clutch adjustment,” says Trzybinski. “This is also available for manual transmissions as part of the Eaton Advantage SOLO product line.”

Automatic transmissions have minimal servicing requirements. Since automatic transmissions don’t have a starting clutch, you won’t have routine clutch damage or need replacements. Routine oil and filter changes are the only regular maintenance required. But it is critical to follow the manufacturer’s oil recommendations. Allison recommends that customers use an Allison-approved TES 295 automatic transmission fluid to extend drain intervals and enhance transmission performance and durability in all operating environments with on-highway products. TES 468 fluids can be used anywhere a TES 295 product is specified.

To compare maintenance between an AMT and automatic transmission, you need to factor in the cost of the oil changes and necessary parts over the lift of the vehicle. “AMTs at some point will need a clutch,” says Schimunek. “Fluid changes over the life of an automatic will be higher cost.” So you really need to weigh all the factors to make the best decision for your particular application.