“In 2020, members of the GCCA came together to agree [to] a commitment to a collective ambition to drive down the emissions of our operations and to deliver society with net-zero concrete by 2050. When we did so, we also promised to provide you with the detail on exactly how we propose to achieve that ambition. Achieving carbon neutrality or a net-zero future and ensuring alignment across our industry on a sustainable way forward involves significant challenges.”

—Albert Manifold, Chief Executive of CRH and president of the Global Cement and Concrete Association, keynote speech during the launch announcement

That vision has now come to a reality as plans have started to roll out. It’s been said that, as a society, we produce and use 14 billion tons of concrete every year. The amount of CO2 emissions involved in the production of cement and concrete construction (globally) accounts for 5-8% of the greenhouse gases. The ultimate goal is to limit global warming by 2º C by 2050.

After making a commitment to limit global warming and nearly eliminate the impact of carbon dioxide emissions from cement production and concrete construction, many organizations around the world have come forward with plans on how to achieve carbon neutrality. In October 2021, the Portland Cement Association (PCA) released its “roadmap” outlining the mission and pinpointing key policies on what the next 10 to 30 years will look like.

Listen to the Rick Bohan interview via the Digging Deeper podcast, "Society Needs Concrete; Concrete Needs Society":

• Part 1

• Part 2

Concrete Contractor spoke with Rick Bohan, PCA vice president of sustainability. Bringing with him an engineering background, he’s been a part of the association for nearly 30 years – a time before sustainability wasn’t even called sustainability. It’s this engineering that has helped him address the problems addressed in the PCA Roadmap two ways: intentionality and optimization. Intentionality by critically thinking about the structures are being built, where they are being built, and how they are being constructed. For “optimization”, Bohan and the PCA wants to consider how can construction be done better in terms of products, processes, technologies, and even workflow.

Q. Various industries and countries have also come forward with a roadmap of their own. Are these a response to the Paris Agreement regarding how industries plan to reduce global warming?

Rick Bohan, VP of Sustainability for the Portland Cement AssociationThe Portland Cement Association

Rick Bohan, VP of Sustainability for the Portland Cement AssociationThe Portland Cement Association

This really goes into our roadmap in terms of looking at two things. Firstly, “society needs concrete.” It's a universal building material. And likewise, “concrete needs society.” And by the way, I wish I could take the credit for that quote, I heard it from somebody else. [Editor’s Note: This quote was said by Albert Manifold, Chief Executive of CRH and president of the GCCA.] For us to reach carbon neutrality, we really have to have everybody who touches concrete involved in our roadmap and involved in that process.

Portland Cement Association

Portland Cement Association

We're looking at an entire value chain. We call it the five C's: Clinker, Cement, Concrete Construction, using Concrete as a Carbon Sink. But realistically, everybody that touches that value chain has a role to play. Of course, the plant—whether it's a cement plant or a concrete plant—but people in construction too. That means the people that are building, the people that are doing the build-outs, the designers, the architects, the engineers, people that operate those buildings.

If you think about it, all of society, because essentially, we're all using concrete to one degree or another, either as a user, a consumer, a buyer, an owner…we all have some level of involvement with that value chain.

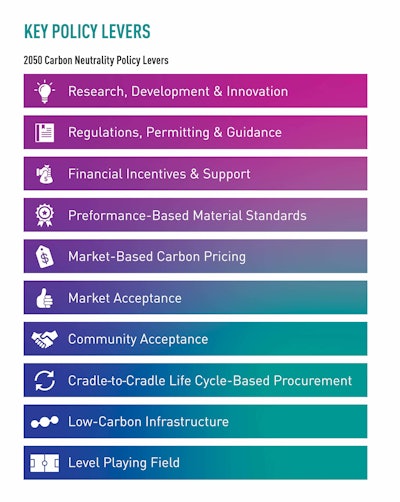

We've identified 10 real primary policy drivers that that would really help us out. I'll just give a few examples.

- One, switching from prescriptive- to performance-based specifications. This is huge. There's no reason why we shouldn't do this. So, prescriptive specifications. It's a cookbook recipe, add a, b, and c in these amounts. Performance specifications focus on the end performance. “What do you want.” My sidewalk, I don't need it to be 10,000 psi concrete. But I sure as heck need it to be durable so that when I put salt down when it snows, that that that sidewalk will have the durability it needs for the next umpteen years.

- Lifecycle-based procurement. People focus on EPDs (Environmental Product Declaration), [but] EPDs are only part of the story. If we want to talk about buying green and green procurement, you have to look at the entire life cycle. It's not enough to have great low carbon embodied materials. We're working on that. We have those available today. But, if those are going to go into a building where we're just going to waste energy over its lifetime, then that's counterproductive.

- We're looking at other issues like community acceptance and awareness. At some point, we need to incorporate carbon capture. What do we do with that carbon? We've got to ship that CO2 somewhere. If we're not next to a place where we can put it into enhanced oil recovery, that's going to require a pipeline. And oh, by the way, if we want to shift to using natural gas as a transitional fuel or if we want to use hydrogen as a fuel, that requires pipeline capacity. Communities nowadays aren't too keen on pipeline construction. We've got to explain to them [that] the road to carbon neutrality is going to require investments like that. And not just pipelines, but also a robust, reliable electric grid. In a lot of areas of the country, we'd like to switch to renewable electricity—that requires added capacity. Again, community awareness. Awareness and acceptance.

It's not a policy, but a lot of these things kind of fall under the rubric of incentivizing innovation and breaking through institutional inertia. We're asking them to innovate. Policymakers [are] naturally risk-averse. We're asking them to be more innovative. That's what breaking through institutional inertia is all about: being innovative. It's not sacrificing safety. It's not being a risk-taker. It's taking the technology we have on the shelf today, making it acceptable and, engaging with it to optimize things.

The PCA made the commitment roughly a year ago. We're not doing this in isolation. Folks in the Cement Association of Canada participate in ongoing discussions with us, folks in the CEMBUREAU (the European Cement Association), European countries, and the Global Cement & Concrete Association participate in our efforts. It's cooperative. It's collaborative. It's coordinating our efforts. And basically, it's a peer review process so that we all get the best roadmap possible for what we need in our particular region.

Portland Cement Association

Portland Cement Association

Q. Are there goals set between now and 2050, like “this done by this year?” How can we track this going forward?

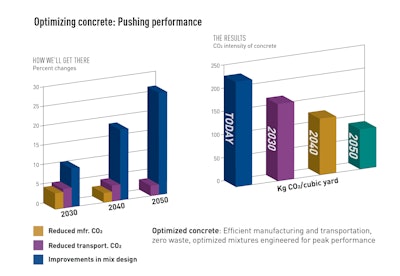

Absolutely. Each one of the steps in the value chain–clinker cement, concrete construction, using concrete as a carbon sink—has targets for 2030, 2040, and of course, by 2050. For example, we'd like to increase, almost double, the use of decarbonated raw materials at a cement plant. Why? Because that goes to a direct reduction of the amount of CO2 released from that chemical. Fact of life. Today, we're just under 5%. By 2050, we want to get to 10%. Now there's a limit because there's an availability issue of those materials. But that's one example.

Reducing the clinker to cement ratio in our cements. Increasing the use of alternative fuels. We've got a number of graphics throughout our roadmap that show what each of these levers can bring to the table. Our goal is to report on the roadmap and the progress with each one of those. I envision that some years are going to be better than others. And we may see where some levers have more impact than others. But, on the whole, we've got these targets aligned, and we're really excited about it. And of course, the angle, carbon neutrality by 2050. But look, I'm really optimistic. I think we can do it sooner.

This really goes to the point about using the entire value chain. There's a lot of focus right now on cement and concrete. But you know, even if you ratchet down the CO2 with cement and concrete, you still have the issue of construction itself. How can you lower the embodied carbon of the construction process itself? There are metrics that we're going to have to develop. Things like, how do you measure the CO2 footprint of the construction process? We're really excited to be engaged with some of the largest contractors in the world, to start to define metrics for that, so that we can actually measure it. Because if we can't measure it…we're really not holding ourselves accountable. I'm really big on making sure that number one, we're completely transparent with the roadmap, transparent with our targets, or timelines, the technologies, our policies. And number two, accountable. It's not enough to have the roadmap, we have to show how we are progressing. We're really proud that we are taking the lead on that as an industry.

Portland Cement Association

Portland Cement Association

We already have really solid data, in particular on the clinker side and the cement side of things. We've been tracking data through our market intelligence group for decades. I mean, literally, back through the 1970s. The US Geological Survey tracks cement shipments, so we know how much cement is shipped throughout the US, and how much is imported and exported. On the cement side, we're really solid with those numbers. Same with the clinker side for the plants.

Now, we don't capture 100% of the plants because we don't have 100% of the cement companies, but we're getting really, really close. And those companies are still even the non-members participating with the USGS. We also know because, by law, our industry has to report CO2 emissions. We also know how much CO2 we are emitting. And as a matter of fact, anyone can go to the EPA website, and they can find out how much CO2 the entire cement industry is emitting plant by plant.

If you know that number and you know the amount of cement that's produced, you can actually figure out what our contribution is in the US. And people are shocked when I tell them this, but I tell them, don't take my word for it—go to the websites. The US cement industry accounts for 1.25% of all CO2 equivalent emissions in the US. I'm not trying to diminish that contribution, but when I hear people say, “Oh, of 6-8%...,” I'm like, wait a minute. It's not. If you want to look at the numbers, look at the numbers that again, by law, we have to report so it is 1.25% 1.25% of just the US—our goal is to get that down.

Our goal, still, is carbon neutrality. We have an obligation to society to address the issue of the age of global warming, we know that we take it very seriously. And we are an industry that is taking the lead to do that. I can't point to any other industry that has this kind of effort in place.

And it's not like the cement industry and the concrete construction industry is doing this alone, that 1.25% is our tiny little segment. There's the steel industry, which has its own segment. There's a supply chain in this industry of the trucks and the trains and the shipping internationally. All of them have effort going into reducing their emissions. This is just our part.

Our hope is that they will look to the US cement industry for a template of how you can do this. We're going to be cooperating with other industries because we don't operate in a vacuum. So, I think there are lessons we can learn from every other industry that's doing this. Likewise, there are lessons they can learn from the cement industry. We're excited about that.

Q. What should contractors ask their plants about?

Don't ask the plant. First, go to the owner and be very intentional. Say, “What are you trying to do with this building? How quickly do you want to build? How will it be used?” and so forth. Sit down with the design team and become part of that team effort. It shouldn't be just the contractor, it should be everybody coming to a consensus saying, [using a high-rise building as an example] “We don't need real high strength for these lobby columns because it won't be occupied for another eight months. So, how about instead of a 28-day strength, we use a fixed 56-day strength?” Now you can go to the concrete supplier and say, “I don't need strength until 56 days, what can you guys do for me?” [The concrete supplier] can then go to the cement supplier and say, “What are the options we can provide this guy?” Make it a team effort.

I think people come up with the answer that they want. And they say, “This is what I need.” I think that's backwards. I think what they should do, again, be intentional about it, and put the question to the entire value chain: “How can we optimize this [project]?”

If you think about it, a lot of this depends on circumstances. If I'm replacing the I-35 Bridge in the Twin Cities, and I've got hundreds of 1,000s of cars that are passing over it every single day, I may not have time to use the 56-day strength. I may need an optimized structure. I may need a higher strength concrete, but I can still do that with a lower embodied carbon depending on what's available in my area. It's a balancing act and it's an optimization act.

Q. The roadmap envisions that construction efficiencies should increase roughly 1% per year until 2050. Are there any areas where contractors can start addressing right now?

Absolutely. I think contractors have such a huge role to play within this. If you think about construction, in general, you have four primary phases. You've got the design phase. Contractors should be involved in the design phase because they have the know-how about means and methods. They're the ones that can tell the architects and the engineers, “This can't be done” or “If you want to do it this way, this is the cost.” I don't mean cost in terms of money but also cost in terms of time. Costs in terms of carbon footprint. They have to be brought in the design phase early on. This is where you get into issues like BIM and augmented reality, workflow, processing, and things of this nature.

Then the construction phase. If you go to a job site here in the US…more often than not, it looks like utter pandemonium. There's chaos. Whereas if you go to job sites in some parts of Europe, you wouldn't recognize it because it is almost a sterile environment. By sterile, I don't mean so much clean, but it's orderly. They have sequenced everything out to the last, you know, hour and minute of the day. When things will arrive, how they arrive, how they'll be installed, who will be on site when they're on site? I mean, they have this down like clockwork. There’s a lot of money to be made by being the innovative designer, the innovative contractor, those are the folks that are making bank.

You're also employing people. You're giving your workforce great opportunities to be involved with a company that isn't just changing the world for the better. And quoting this building out there, that's going to last for decades, you're also providing an economic engine.

That's in the construction phase. In the use phase, concrete has such a huge role to play. We know that concrete buildings with the thermal mass, resiliency, fire resistance, earthquake resistance, the fact that a concrete building can stay in operation 24/7 through tornados, hurricanes, fire, windstorms, floods—that has a huge dividend; that cuts operating expenses for a building. And then finally at the “end of life,” and I hate that term, because there's no such thing. It's not a cradle to grave, it's cradle to cradle. Finally, using that concrete building decades from now, when we're both long gone, using that for fresh concrete with…other types of cements using that for new [buildings.] That's the role contractors have to play. I get passionate about it because I'm so excited. I'm also frustrated, because I see so many contractors that are just kind of shaking their head, and they're like, “yeah, this is pie in the sky.” No. This is today's technology ready for people willing to take the opportunity.

We're very transparent about the roadmap. People can go online. They can download it. They can read it. It's right on our website. We're taking all the responses we can get from people. It's going to be a dynamic document. People are going to give us input and feedback, you know, over the next 30 years. It's not going to be stagnant—we've got to hold ourselves accountable.

I think we will be revising it. It won't be daily, weekly or monthly. But I think we're going to be taking a look probably every, every 6-8 months, taking a step back and saying, “okay, what have we done that's worked. What are the success stories? Where are the areas We need to focus on? Where can we engage policymakers to help us accelerate where we're not getting to the targets?”

Q. Do you think it would help if contractors made a road map of their own? And if so, what would you suggest they start with?

What I would love contractors to do is download our roadmap and put up the graphics that we have in the roadmap. Put those up in their jobsite trailers. In their offices. Point to them and say, “Hey, this is what they want to do. How can we contribute to that?” And you know what, there's a role for them to play. Maybe they become more willing to accept portland limestone cements. Maybe they become more willing to look at their workflow. On the construction site, maybe they become more willing to look at zero-emission material handling equipment on the jobsite. Things like that. I think if they do that, if they start thinking outside the box, and start really what iffing.

The one chart that I would ask them to really focus on: optimization. They're shifting the curve and shaping the curve, but the one I want them to focus on is shifting the curve. You have some of the most innovative contractors out there. They're the folks pushing the envelope every single day. If I was a contractor, I'd want to be one of them. I want to be one of them, as opposed to one of the slow adopters. Now, sometimes the slow adopters, it's through no fault of their own. But that's where I want to have my company, my staff, pointing to that star performers saying, “Look, folks, we're going to be at the cutting edge in our company in what we do, how we do it, when we do it, and where we do it.” That's what I'd like them to do.

I'm passionate about it. I'm excited about it, because we have a solution. And I would encourage everyone if you have questions, if you want to put us on the spot, if you've got input, we're here.

Concrete needs society. society needs concrete. Those two things work hand in glove together.