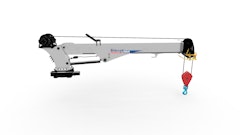

Liebherr has expanded its product range with its new hydraulic luffing jib crane, the 195 HC-LH 6/12. The top-slewing crane is designed for urban areas. With a minimal working radius of 3m and an out-of-work position of 10 m, the crane can be adapted to construction site conditions.

The hydraulic luffing jib crane combines the performance of Liebherr luffing jibs with powerful hydraulics. The result is a top-slewing crane that can be positioned centrally onsite. All of this comes together to make the 195 HC-LH 6/12, with its lifting capacity of up to 12 tonnes in two-fall operation, a solution for construction operations.

“We provide a setup that’s strong in all aspects, from transport and assembly through to operation, and can offer our customers an outstanding overall concept for their sites,” said Markus Kinateder, product manager at Liebherr-Werk Biberach GmbH.

Design and Applications

The 195 HC-LH 6/12 can be adapted to various conditions onsite and requires very little space. This adaptability is achieved through being able to install the crane in lift shafts, its reduced out-of-service position and minimal swing radius and the fact that the cabin is mountable on either side.

A lift shaft installation with subsequent internal climbing is possible using the 16 EC 240 tower system. The crane can be centrally positioned onsite where it can lift up to 2,550 kgs at its jib head at maximum radius. Its minimal working radius of just 3m also helps promote coverage from a central point. In practical terms, this means that a small crane can be used rather than a large machine that would need to be set up next to the building. Another option alongside the slim 16 EC 240 is the widely used 21 HC 290 tower system, which enables high hook heights and installation of the EasyUp 200 crane driver elevator. Both tower systems come prepared for climbing inside and outside buildings.

The cranes can be positioned closer together when several machines need to be used on the jobsite. This allows more cranes to fit into the available space when required. A reduced out-of-service position of 9.6m for jibs 45m or longer makes it all possible. The jib can be extended in 5-m increments. At maximum tower height, the out-of-service position measures up to 14.6 m. Thought has also been given to tight spaces in terms of the crane’s swing radius: the counter-jib has a swing radius of 7.9m and its ballast blocks are stackable.

The cabin can be mounted on either the left- or right-hand side to meet individual site requirements and building proximity needs. It’s possible to position the crane close to the building this way, which gives the crane operator a better view of the load and surrounding environment.

Liebherr

Liebherr

Transport

Four trucks or containers are enough to transport the HC-LH to its next job location. With the jib width being 1.15 m, three sections fit onto a standard truck or in one container. Length isn’t a problem either: the jib end section can be slid into the counter-jib and all platforms and rails can stay attached to the counter-jib. The hoist unit is also installed on the jib, allowing it to stay in place during transport and stay protected.

The slewing platform and central unit can either be lifted onto the truck pre-assembled or part by part ready for individual assembly. The choice depends on which mobile crane is available for the later assembly of the components, which can weigh up to 8 tonnes. A smaller mobile crane can be used for lifting component assemblies, while a more powerful mobile crane is capable of handling the pre-assembled jib and counter-jib unit in a single lift. The crane’s jib can be completely pre-assembled on the ground. The hoist rope and hook block can be reeved ready for use so that working at height isn’t required.

Operation

Liebherr’s luffing jib cranes can be used on sites with heavy components and high hook heights. The luffing system enables luffing in under 90 seconds. The jib can be adjusted safely and at controlled speed with a load on its hook. Load-Plus is now available for luffing jibs thanks to the launch of the new crane. A load increase of up to 25 percent can be achieved at the touch of a button for heavy one-off lifts.

The 195 HC-LH comes equipped with the new Tower Crane OS operating system. A menu bar allows navigation and the user interface can be customized to suit different users. The crane’s LiCAB cabin enables visibility. Three different versions of the cabin are available.

![[VIDEO] Liebherr Standard Full-time Automatic Power-split Transmission First for Industry](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2015/11/default.56391436a6249.png?auto=format%2Ccompress&fit=crop&h=75&q=70&w=75)