Volvo Penta’s Stage V engine concept, unveiled at CONEXPO-CON/AGG 2017, will include its entire range of engine models with power outputs of 143 to 770 hp. Bjorn Ingemanson, president and CEO of Volvo Penta, says the company leveraged all of the competence within the Volvo Group and talked to key customers in order to develop a tailor-made solution that will meet current engine needs, as well as be optimized for future installation and emissions legislation requirements.

According to Christer Hedstrom, Volvo Penta product planning manager, the big difference between the company’s Stage V engines and its Stage IV models is the addition of a DPF to meet the new PN requirement. “Due to that, we’re also adding some devices on the engine to optimize it for good system regeneration, and provide as much uptime as possible,” he says.

The Volvo Penta Stage V engine concept features a common rail injection system to help reduce fuel consumption.

The Volvo Penta Stage V engine concept features a common rail injection system to help reduce fuel consumption.

The exhaust aftertreatment system (EATS) will combine a DPF, DOC, DEF, SCR and ammonia slip catalyst. This two-box unit can be installed in various ways. “We have several hundred types of customers, so we need to have large flexibility depending on what type of installation the engine will go into,” says Ingemanson. The company is also looking to make the system as compact as possible to further aid installation.

The company will use the same hardware layout and electrical architecture to ensure consistency across its range of Stage II to Stage V engines. This will make it easier for OEMs developing machinery for markets with varying emissions regulations. In addition, the high efficiency of the EATS helps reduce engine complexity.

SCR-based Solutions

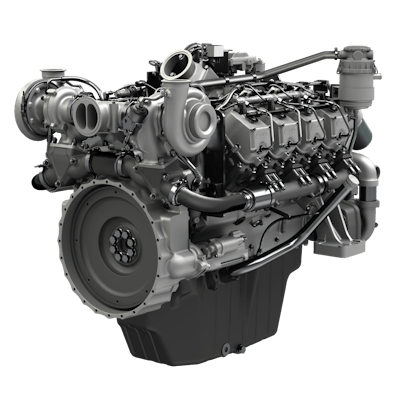

FPT Industrial’s new V20 engine includes a common rail injection system that works in tandem with the engine’s electronic control unit to reduce fuel consumption 2%. Further aiding efficiency is an internal turbocharger with cross-bank exhaust system. The engine features a V8 architecture that FPT says provides a 13% improved power-to-weight ratio over V12 alternatives, while still providing the same power and performance as a V12.

To meet Stage V, the V20 will use HI-eSCR technology rather than a DPF or EGR. The in-house designed HI-eSCR system uses SCR on-filter technology and PM filtration integrated onto the SCR system to meet emissions requirements. It is modular, enabling up to 20 different layout possibilities. Various aftertreatment mounting options ease installation.

MAN Engine’s D2862 LE13x will also meet Stage V with an SCR-only strategy. According to the company, omission of an EGR system helps lower heat dissipation from the engine, which allows the use of a smaller radiator, minimizing space claim. Its aftertreatment system is modular in design, as well, enabling various installation options of the individual components.

Tier 4 Final Benefits

While there is no equivalent to Stage V yet planned for the U.S., many of the engine designs are compliant with Tier 4 Final, as well.

According to Hugh Foden, executive director, Cummins Off-Highway Business, North American OEMs can also benefit from the technology enhancements being made to the new engine designs. Improved performance, efficiency and packaging are all features OEMs will gain by using the next-generation engine designs. For example, Cummins’ Tier 4 Final/Stage V engines have a smaller, lighter package design than the previous generation and reduce overall fuel and DEF costs up to 3% compared to the current Tier 4 Final range.