With general contractors and subcontractors pricing construction projects at low prices, you have no option but to look for ways to reduce your costs to compete. Finding ways to lower your field costs will allow you to be more competitive and make a profit.

Material costs are relatively the same for all contractors and can’t be reduced much. Therefore, labor, as the largest part of most contractor’s total job cost, must be addressed as the logical choice to reduce field costs with careful planning to implement an effective production cost reduction campaign.

Construction field production labor usually runs about one third to half of the total job cost for most construction trades. The best and easiest method to lower job costs is to start a productivity improvement program by taking small simple steps one by one. Each step or standard will reduce your costs by small percentage points which will add up to large overall improvements that make a real difference.

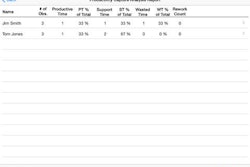

10% improvement = 3.3% savings

Imagine you made a company goal to improve your annual field labor costs by 10%, which only equals to six minutes per hour. Could you make a commitment to achieve a six minute improvement goal per hour? And would it really help your bottom-line enough to make it worthwhile? Let’s look at the numbers:

- Total annual sales = $1,000,000

- Total annual labor at 33% of total sales = $333,000

- Improve labor productivity 10% savings = $ 33,000

- Net annual labor savings = 3.3 %

For a small labor productivity improvement of only 10%, your company is now 3.3% more competitive in the marketplace. By reducing your overall costs by this 10%, you might also be able to increase your total volume, which will add even more to your net profit. Now what simple standards can you implement to improve your field labor costs?

Read next: How to Set and Track Construction Production Goals

Start by finding things to fix

Improving field labor costs starts with identifying areas to fix that are bogging down, slowing down or holding the crew back from operating at its maximum capacity. These productivity pressure points are caused by many field project factors including:

- poor planning

- lack of supervision

- untrained crews

- lack of materials

- wrong equipment

- waiting for decisions

- bad attitude

- mistakes

- out of sequence workflow

- missing materials

- broken or lack of proper tools

- no standard field systems

The average construction field crew wastes around two to four hours per day waiting, talking, walking, smoking, taking long breaks, starting late, finishing early, looking for materials, waiting for their boss to tell them what to do, or trying to look busy.

- their start times, end times, break times, lunch start and stop

- if and when the crew meets with their foreman

- how they roll out the tools and cords

- if they keep the site clean

- how they care for the tools

- if their storage area is organized

- how often and how far they have to walk to the toilet

- cell phone use

- smoking while working

- location of power poles and access gates

- site layout and logistics

- location of trash bins

- jobsite congestion

- crew production activities versus waiting for their boss to show them what to do

- any other activity that’s distractive or disruptive to their proper productive flow of work

Looking for simple ways to fix these problems is not hard to find if you get your field crew together and ask for their ideas and input on how to improve productivity.

Read next: Margins, Mark-Up & Making Money!

Start with establishing standardized company-wide employee job rules. Get everyone to agree on the following and create company simple standards:

Employee jobsite rules

- What does start and finish time mean

- What does roll-out and roll-up time mean

- What does a 15 minute break mean

- What does a 30 minute lunch mean

- No smoking during working hours

- No personal cell phone use during working hours

- Drug and alcohol use

- Safety attire, gear and hardhats

- Dogs or radios not allowed

Jobsite responsibility and logistic rules

- Daily crew meetings

- Job daily cleanup

- Weekly punch-list walk thru and completion

- Jobsite daily safety inspection

- Who can go to the hardware store

- How many times someone can go to the hardware store

- Who’s in charge when the foreman leaves the jobsite

- Who can operate equipment supervised or not

- Jobsite logistics and layout to reduce walking

- Power pole and toilet locations

- Material storage location to reduce transportation

- Trash bin requirements and locations

- Tool and equipment maintenance standards

- Organized storage and tool bins

Follow The McDonalds Rule

As a construction business coach, I often facilitate company field foreman and superintendent meetings to help companies decide how they want to do business and create field standards to increase overall field productivity. When we start, many foremen don’t want to deal with a set of standard rules or have to manage their crews on these difficult to enforce items.

But in reality, these factors and pressure points can add up to lots of wasted dollars. When employees know what the rules are, they follow them. I always bring up what I call “The McDonalds Rule.” If employees at McDonalds can’t do it, we can’t either.

For example, at McDonalds, if an employee is late, he doesn’t keep his job long. Employees also can’t smoke or use the cell phone while working. Or if they take too long a break or lunch, they get a warning and their pay gets docked. No excuses or exceptions. It shouldn’t be any different at a construction company.

By implementing these simple field standards, your productivity will improve by at least 10% or more. Get your team involved and start a competition to find ways to save money by being more organized, plan better, and setting simple and clear standards for everyone to follow.

George Hedley CPBC is a certified professional construction BIZCOACH and popular speaker. He helps contractors build better businesses, grow, increase profits, develop management teams, improve field production, and get their companies to work. He is the best-selling author of “Get Your Construction Business To Always Make A Profit!” available on Amazon.com. To get his free e-newsletter, start a personalized BIZCOACH program, attend a BIZ-BUILDER Action Plan Boot Camp, or get a discount at www.HardhatBIZSCHOOL.com online university for contractors, E-mail [email protected].