Read just a handful of how-to-succeed books or articles and you're sure to come across the frequently acclaimed secret to financial success: goal setting!

Goal setting really is great advice that somehow gets overlooked in the daily operations of construction companies. Construction crew after construction crew is sent out the door without daily production goals.

Setting Obtainable Goals in a Down Economy

Contractors typically send their crews out on jobs with work scopes, needed tools, miscellaneous materials and a completion date. The completion date being a date they must finish the job by - be that one week or one year from today.

Production managers almost never send crews out with specific production targets. Rarely are they told, "You need to finish this amount of work before you go home today." Uncommon is the crew who heads out the door with a production goal that correlates work quantity to man-hours

budgeted. Rare is the crew who is kept aware of its productivity to date versus budgeted productivity.

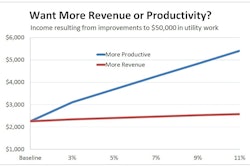

Production goals matter. They matter greatly. The have a direct impact on profitability. They have a direct impact on competitiveness. Crew production goals are also the toughest business system to get just right.

The pendulum swings from not tracking productivity rates (work performed divided by man-hours used) to tracking the production by each cost code used by the estimator. The proper depth of tracking varies from trade to trade and contractor to contractor. The larger the business the easier it is to track detailed cost codes. The smaller the average sized job, the less detailed the tracking should be. Every contractor should be setting, tracking and monitoring crew productivity at what we refer to as the benchmark level.

For example, a drywall contractor's benchmark may be based square feet of drywall completed. A plumber's may be based on total feet of pipe installed. A painter's may be the number of gallons used. A mason's may be the number of blocks or bricks installed.

Your initial benchmark productivity measurement is likely to be a single measure of work output. Once you and your crews become comfortable with budgeting and tracking the single benchmark, expand the tracking to include one or two more. The next two to three are most likely to be major preparation tasks. A drywall contractor is apt to start tracking the square footage of drywall hung and the square footage of drywall finish sanded.

Increase your tracking detail as you would walk down a staircase in complete darkness. Step down gently. Regain your balance. Then step down again. Repeat until you reach the bottom. Expand your benchmark complexity in a similar manner - one step at a time.

Once your estimator gets a taste of production tracking he will lobby for excessively detailed tracking. That would be the right course - if it weren't for the disruption excessive tracking causes the field crews.

Production tracking is a balancing act. It takes time away from the real work. Done right, it doesn't rob a foreman of more than 10 minutes a day. Done wrong it will take over 30

minutes a day and much of the data will be garbage.

Once you and your crews master setting benchmark goals and monitoring progress you can use sampling to acquire the cost code level production data that your estimator desires. I've seen this approached used by several large contractors. It is a great way to check estimating assumptions and improve those that turn out to be in error.

The way to sample is to assign one specific cost code level tracking to each crew. This would be in addition to their normal benchmark code tracking. For example, an insulation crew may track the time is takes to insulate the 2-inch and smaller domestic HW water pipe that is 10 foot AFF. There is no level of cost code too detailed to use this approach on. Frankly, it is the only way you and your estimator will ever dial in your estimating system accurately. Without this

approach, all estimating is guess work divorced from reality.

Once you've begun setting goals and collecting field data you may have the instinct to jump a crew who appears not to have accomplished anything that day. Don't over-react to daily

productivity fluctuations. A week's window is the right time period to react to.

Furthermore, give the foreman the benefit of the doubt. Find out why the production is running behind. It may be due to the preceding trade. It may be due to a lack of approved shop

drawings. It may be due to material delivery delays. It may be due to one sloppy, lazy crew member. It may be due to someone forgetting to tell them the goals and providing them

with feedback on the running performance. It may be due to your foreman not being cut out to run a crew. You will never know the cause until you visit with the foreman.

Daily production targets are relatively easy to set if you invest a little thought into how to measure field productivity. Have you figured out how to measure your company's field

productivity? If not, it's time to get started. Your financial wealth depends on it. Set daily goals. Monitor progress. Reap the rewards!