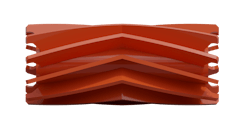

McCloskey International has unveiled the new J4 jaw crusher with new features for hard rock applications. Designed to withstand tough conditions, the J4 delivers high production due to its jaw chamber design and material flow. The large 1060mm x 700mm (42-in. x 28-in.) jaw opening accommodates large feed sizes, contributing to production in material processing.

The material path is enhanced with the 1064mm x 4247mm (41.9-in. x 167.2-in.) grizzly pan feeder under the hopper that allows for sizing of material with a variety of mesh options. Options of either a short pan feeder to suit the pre-screen or a double deck grizzly pre-screen are available for sizing of material based on the required end product.

The J4 offers a choice of either a two deck or one and a half deck system. The two deck delivers an extra product spec over the mid-size product conveyor.

The J4 also delivers stockpiling, with wide main and side conveyors for material flow. The angle adjustable 1200mm (48-in.) wide ToughFlex main conveyor has a 3.912m (12-ft. x 10-in.) high stockpile, and with quick release and ground level access, with the belt offering access for maintenance. ToughFlex is constructed with a special weave of two fabric plies and an additional binder warp (without the need for steel wire) resulting in reduced belt weight. The plies are reinforced to resist puncturing and are protected with heavy-duty wear resistant top and bottom covers. At the end of its lifespan, ToughFlex belts can be recycled unlike belts reinforced with a metal ply.

While a side conveyor remains an option for many jaw crushers in its class, the J4’s integral folding conveyor is standard and has a 650mm (26-in.) adjustable speed belt fueling a stockpile height of 3.44m (11-ft. x 3.6-in.). In addition, the recirculation conveyor can be rotated 90 degrees to be used as a stockpiling conveyor.

McCloskey engineers have designed the J4 to meet the evolving requirements of today’s projects and operations. Mobility on-site and between sites continues to be a feature with remote control tracks to move and position the crusher.

The J4 is equipped with a number of features to ensure the workplace and the operator are secure. Engine safety shutdown systems, start-up alarms, full safety guarding, external maintenance access and a tagout capability on the isolator all contribute to the safe operation and maintenance of the equipment. Ground level access also promotes safety and allows for service and maintenance, reducing the downtime for the operation.

“The J4 continues the momentum for our jaw crushing product range, as we continue to develop new products that meet the evolving needs of our customers across industries,” said Toni Laaksonen, senior vice president, McCloskey International. “We have always designed our equipment to ensure it contributes to the productivity and business success of these operations. As a company that is involved in the handling and processing of the earth’s resources, we also have our sights set on sustainability. Our next commitment to an environmentally responsible strategy will be the introduction of our electric crushers, scheduled to be available in 2023.”

The crushers are designed for aggregates, construction and demolition recycling, as well as site preparation.