Just before 1 p.m. on Tuesday, December 11, a 20-inch-diameter, 20-foot-long gas transmission line exploded within a few yards of the southbound lanes of I-77 near Sissonville, WV.

The explosion leveled four homes and badly burned a fifth home in the surrounding area. The flames from the gas line shot several hundred feet into the air and across both the southbound and northbound lanes of I-77 for a little over an hour until the gas company was able to shut the line off. This resulted in the scorching of 800 feet of the asphalt pavement in both directions.

Large rocks and debris were scattered over the entire interstate from the blast. Guardrails and road signs on both sides of the interstate were badly damaged, as well as a steel grate covering an inlet in the median. Miraculously, no one was killed or even seriously hurt.

Despite being severely burned and damaged by the blast, the 800-foot section of I-77 was replaced and reopened by Wednesday morning. In less than 15 hours, workers from the state Division of Highways, West Virginia Paving and American Asphalt Co. were able to turn the scorched road into a smooth stretch of highway.

Paving companies to the rescue

After the explosion, the West Virginia Department of Transportation (WVDOT) contacted Chet Rodabaugh, paving manager for West Virginia Paving, located in Dunbar, WV. "They requested us to mill and pave both the northbound and southbound lanes," he says.

Rodabaugh and West Virginia Paving’s Dispatcher, Dallas Moore, immediately put a plan together to contact a paving crew from that area, call hired haul trucks, and notify the equipment shop of the equipment needed for milling and paving. They also asked American Asphalt of West Virginia, St. Albans, WV, to provide the material to be used.

"Everyone that was asked responded without hesitation and readied themselves and the equipment for what we knew would be a long, cold night of work," says Rodabaugh.

West Virginia Paving crews and equipment started arriving at the project site at 5 p.m., Tuesday, December 11, and began to survey the damaged road.

"We calculated what we thought it would take for repairs," says Jack Withrow, Environmental Compliance Officer for West Virginia Paving. "Initially, the WVDOT projected it would take at least 24 hours to get the road milled and paved. I spoke to the paving foreman, Travis Truman, and his response was, 'We can get it done quicker than that.'"

Rapid response

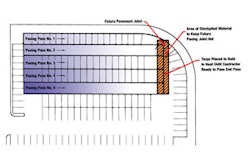

West Virginia Paving started the rapid response paving process by using two tractor brooms to sweep and clean off the rocks and debris on the northbound lanes of I-77. After this was done, a Wirtgen W150 milling machine was used to mill the northbound and southbound lanes. The average milling depth was 3 inches, but there was a 300-foot section of the southbound lanes closest to the blast that needed milled to a depth of 6 inches.

Once the milling was completed on the northbound lanes, the paving crew began to pave the northbound lanes with a Marshall HMA skid-resistant surface mix. Paving was completed around 11:30 p.m., but the crews had to leave the project site in order for the gas company to test its gas lines.

"We were able to get back onto the site around 3:00 a.m.," says Withrow. "After the lines were painted, the WVDOT opened up the northbound lanes at 3:30 a.m."

At 3:00 a.m., the paving crew started to pave the southbound lanes. "We laid 306 tons of Marshall HMA base mix in the 300-foot section that was milled to a depth of 6 inches. We then finished paving the southbound lanes around 7:30 a.m. with the Marshall HMA skid-resistant surface mix. The lines were painted, and the WVDOT opened the southbound lanes back up at 8:05 a.m. – 15 hours from the time we arrived at the project site."

The challenges of rapid repair paving

There were several challenges West Virginia Paving faced with this emergency HMA paving project during the second week of December. These included:

- Most asphalt plants were shut down for winter maintenance

- All paving crews were off for the winter

- All of the milling and paving equipment was at the shop for winter maintenance

- Temperatures the night of December 11 were down into the low 20s

- Night paving

- Gas company shut down the surrounding area from 11:30 p.m.-3 a.m. to test remaining gas lines in the area; crews were shut down and off the project site while this took place

Luckily, asphalt producer American Asphalt of West Virginia was still open and operating. "If needed, we also had a West Virginia Paving plant in the area that was still hot and had not been completely shut down for the winter," says Withrow.

Chet Rodabaugh and Dallas Moore worked together in contacting the paving crew members, shop and hired truck drivers. "Everyone that was contacted was more than willing to drop what they were doing and come out and help," says Withrow. "Rodabaugh received several calls from paving crew members around the state of West Virginia and Kentucky asking to help out."

One factor was on West Virginia Paving's side. "In a normal interstate paving project, we have to set up and take down lane closures," says Withrow. "But in this case, I-77 was completely shut down by the WVDOT. This allowed us to save time.

"We were able to bring our crews and equipment right up onto the interstate without any delays from traffic," he continues. "This also allowed our haul trucks in the milling and paving process to get on and off the interstate quickly. With the temperatures dropping down in the low 20s that night, this also helped in getting the material out to the project in a timely matter."

The cold also affected equipment operators. "Our roller operator did a great job of staying right with the paver all night," says Withrow. "For those that have been on a roller when it’s cold outside and the water mist is hitting you in the face … COLD!!"

While West Virginia's crew is experienced with night paving, and the equipment is ready for night projects, Joe Burgess, safety director, was still on hand giving instructions and prepping the crew before the project began. "Burgess went out and accessed the project and spoke with the crew members before the milling & paving project even began," says Withrow.

It takes a village

West Virginia Transportation Secretary Paul Mattox says he has never seen damage to a road like what he saw on I-77. "The road was crunching. The guardrail had melted. I've never seen damage like that before," he says.

Officials thought it would take at least 24 hours to reopen that section of interstate. Fortunately, the fire didn't damage the underlying concrete as much as highway officials initially thought it did.

Withrow and Rodabaugh credit the hard work and versatility of the West Virginia Paving crew for finishing the job so quickly.

"You can't do a job like this without good employees," says Rodabaugh. "Everybody stayed calm and positive as things changed from minute to minute. We had a good crew that was committed to getting the job done."

Members of the community stepped up and helped make the night go a little easier too. "We would like to recognize that the local Red Cross that came out to the project and provided food and drinks during the night," says Withrow.

The bottom line is that everyone came together to finish this rapid response paving job successfully. Rodabaugh concludes, "We were just glad to be a part of the response and able to help out to reopen the road."

Additional information provided by Jared Hunt, Charleston Daily Mail.

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)