As the largest paving company operating in the Tampa, FL market without an asphalt plant, Pete Hernandez, president of Tampa Pavement Constructors Inc., decided the time was right to make the investment to own his own plant.

"We had become Tampa's largest FOB (Freight Onboard) paving company without a plant and we wanted to sustain our volume, and hopefully position ourselves for future growth," says Hernandez, who started the business eight years ago. "Our decision was based primarily on the fact that we couldn't always get the volume we needed when we needed it. It was a cost issue of having trucks (both company-owned and independent drivers) waiting for a load. If the wait was too long, we often had to send them to another plant (asphalt producer) and both situations caused delays for our paving crews."

Hernandez says Tampa Pavement Constructors focuses on a niche in the paving market, by serving private residential and commercial customers, and industrial customers, along with small city and county projects, and small DOT right-away projects. Along with sustaining the current volume for those customers, Hernandez also hopes the new plant investment will allow his company to take on larger city and county projects.

"We carefully thought out the decision to own our own plant based on our current volume of approximately 200,000 tons a year and the fact that owning a plant would also allow us to increase the volume of work by going after projects we couldn't deliver in the past," Hernandez says.

Selecting a plant

Hernandez evaluated several different plants and decided the ADM (Asphalt Drum Mixers Inc.) Milemaker MM225 Asphalt Plant best served the current and future needs of Tampa Pavement Constructors.

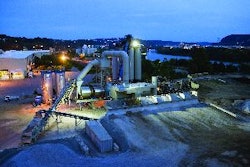

"I like ADM's counterflow/post mixer technology and the plant footprint fit the land we purchased for our production operation," he says. "The site permit allows us to produce a maximum of 500,000 tons annually, and selecting a plant that fit the space and allows us to increase our production requirements in the future was important. This plant will allow us to produce between 400,000 and 500,000 tons annually, and that will meet our growth objectives for some time, while still staying within the permit restrictions."

While the initial upfront cost of purchasing land and a new plant will take time to recoup, it has increased the contractor's flexibility to respond to mix requirements without relying on other producers.

"Now we're in control of the mix designs we need to satisfy our customers, and we have control of the costs to deliver that mix to the projects we're constructing," Hernandez says. "We no longer have to wait for our truckers to receive a load at another producer's plant. So there's an immediate value in being able to control the trucking and pricing of delivering mix to a project. In the past it wasn't uncommon for us to send a truck to XYZ plant and that driver wouldn't leave that plant for 2 to 2 1/2 hours because he had to wait in line to receive a load. Now, when a truck shows up at our plant, it's loaded and sent out to the project. So, there is a definite advantage of owning a plant to supply the jobs you're working on."

But Hernandez is quick to point out that spending $2.5 million on a plant and another couple million to purchase and develop land to accommodate an asphalt production facility is a substantial commitment for any contractor to make.

"We realized we had the volume to justify that kind of investment, and we also knew it would diversify our operation and give us the ability to increase our market potential," he notes. "With the new plant and our location, we now have a much larger market share potential to pursue. We're close to our aggregate source (9 miles from the Port of Tampa) and we're within 5 miles of all three major interstates that serve the area. So, we're now in a position to serve a seven county market."

The plant

The ADM Milemaker MM225 asphalt plant Tampa Pavement Constructors brought online this past August has a 175 ton per hour production rate based on the following conditions: 275 degree F fan gas temperature, 300 degree F material temperature, 70 degree F ambient temperature, 650-feet above sea level, 50 percent excess air, 10 percent casing losses, 5 percent leakage air, 10 percent moisture removal, 5 percent liquid asphalt, and 20 percent minus #8 materials. Components installed include:

- MM225 Dryer - A 7-foot 4-inch-diameter by 30-foot-long rotary drum with alternating flight design that provides high efficiency material veil, and an exhaust gas incineration collar that allows mixing drum gases to be incinerated.

- MM225 Mixer - A 6-foot-diameter by 16-foot-long rotary drum, with 1 1/2 inch exterior insulation and staggered, adjustable flight design for maximum mixing efficiency and consistent mix quality. The mixing drum gas recovery fan channels gases back to the burner flame for incineration, which also reduces fuel consumption.

- Ecostar ESII-75 Burner Equipment by Hauck Manufacturing Co. - A 75 million Btu/hr sealed burner with adjustable flame-shaping capabilities. The burner at Tampa Pavement Constructors if fired by #5 waste oil, which is delivered to the burner by a MM225 Reclaimed Oil Pumping System with Inline Heater

- BHS585-10 Stationary Baghouse features a 47,000-acfm air volume design with 9,185 square feet of filter area that provides a 5.1:1 air-to-cloth ratio.

- 5CFB30 Cold Feed Bins - Each of the five cold feed bins measures 14 feet wide and 10 feet deep and has a capacity of 30 tons based on material density. Steep-sloped sidewalls ensure free flow of material, with two of bins equipped with electric bin vibrators to enhance the flow of wet or dense aggregates.

- RAP15 Recycle Bin and Feeder System - A 15-ton rated capacity system that includes a recycle bin grizzly, intermediate recycle conveyor, recycle lump breaker, RAP2465 Recycle Weigh Conveyor, single deck Deister Scalping Screen and reject conveyor.

- WC3050 Weigh Conveyor - A 30-inch-wide by 50-foot-long weigh conveyor, powered by a 10-hp by 1800-rpm motor, weighs and transfers material from the scalping screen (Double-Deck Deister 4' x 8' Scalping Screen) to the drum fast feed conveyor.

- SS100 Stationary Silos - Two 100-ton silos feature a 6,000-pound enclosed batching hopper with dual clam gates to maximize use of barrel volume while minimizing segregation. The silo cones include AR liner for extended maintenance life.

- Vertical AC tanks

- Plant control system

Purchasing: The right decision

For Hernandez and Tampa Pavement Constructors, the decision to purchase a new plant, an ADM Milemaker MM225 in particular, was the right decision.

"We believe this plant gives us the flexibility to go up or down depending on the market conditions," Hernandez says. "We can easily grow our business up to 400,000 tons annually with the plant and permit we have to operate it. When we purchased the plant we upgraded the baghouse and the burner to allow us to produce up to 250 tph, and that will more than handle our paving needs."

With all of Tampa Pavement Constructors' mix designs compliant to Florida Department of Transportation specifications, the addition of a recycling system will also prove to be a good investment on future city, county and DOT projects.

"You're allowed up to 30 percent RAP (reclaimed asphalt pavement) on all structural mix designs and we now have a plant that's capable of producing those mixes," Hernandez says. "Since we follow DOT mix specifications for all the mixes we produce and place for private commercial as well as city, count and DOT projects, the plant recycling capability will further enhance the efficiency of our production.

"The plant is exceeding our expectations," Hernandez states, "and as we go into a new year with a backlog of work, it's our intent to protect the market we have and pursue new opportunities. We believe owning and operating a plant will help us do just that."