Jack Porter had a better idea. As a fourteen-year veteran County Commissioner for Grady County, OK, he is responsible for all the road maintenance and repairs in District Three. With roughly 515 miles of blacktop to manage, the volume of asphalt consumed by just his one district (the County has three) is quite considerable. But the rising costs of petroleum, for both the road oil that goes in the asphalt mix and the fuel burned in the transportation to deliver a load, saw Porter's budget getting blown in no time. So he found a way to make his own, and will save the County hundreds of thousands of dollars by doing so.

Grady County is located in oil country, and while Porter's district may not have a huge population of people, it definitely has a large population of trucks. With a landfill in the district, three refineries and an oil disposal well, the roads take a beating. "Last year, we had three major floods too, so that didn't help the roads either." All that pressure adds up to plenty of road repairs, which, among all his other responsibilities to the County, keep Porter plenty busy.

The 1,200 square-mile County in central Oklahoma has always dealt with road repairs as just that - a repair. "We had chip sealed our roads for years and years," Porter explains. "But we wanted to take it up a notch and start doing overlays. Since the trucking and cost of blacktop in our area made that cost-prohibitive, we began exploring a way we could afford to make our own."

One would think that such a search would inspire 'solution-oriented' dealers to step up and help find an option that would make that idea a reality. But Porter admits that really wasn't the case. Jim Harmon from The G.W. Van Keppel Company's Oklahoma City branch was the exception. "He showed an interest in wanting to help us solve our problem right away," Porter explains. "Jim sat down with us to better understand how we wanted this to work, and pointed us to the KPI-JCI pugmill plant. Obviously, the pugmill is core to the process of creating that blacktop, so that's where we began to build our process."

With the addition of a pugmill plant, Porter's team would be able to economically - and consistently - mix asphalt at a rate and scale to meet a higher repair standard. "This wouldn't be the first time we've made our own asphalt," Porter admits. "We've done that before here, mixing with graders and other means, but it's a rather cumbersome and slow process. And we had no way of ensuring that each batch came out the same." Creating material in the volume necessary for resurfacing projects would require a more purpose-built solution.

Harmon arranged for Grady County representatives to visit other installations, one in Waco, Texas and the other in Wichita, Kansas, to allow them to see the pugmill plant in operation. Porter found the opportunity to be extremely valuable. "That was really helpful. We really appreciated Jim making that effort for us because we knew we needed [a pugmill] but we'd never really been around one or seen one work. So to get to talk to other people using it and watch it work was such a benefit.

"We talked to a number of others who were using KPI-JCI pugmill plants, some of which have been in use for quite awhile, and they all had great things to say," recalls Porter. "They hadn't experienced any out-of-the-ordinary problems, required easy maintenance and made a great, consistent product. We saw what was coming out of those units in Waco and Wichita for ourselves." The KPI-JCI team contributed as well. "Walt [Wooten, regional manager for KPI-JCI] was really helpful representing the product and ensuring we were comfortable with the service they offered. He really helped to make it happen."

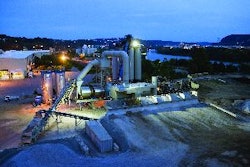

After some additional research and planning, Grady County District Three purchased the KPI-JCI model 52 pugmill plant before the start of the 2008 season. The diesel-electric plant includes a 6-foot pugmill with a hopper feeder, oil injection system and feeding conveyor. Capable of producing up to 200 tons per hour, the mid-range system was the perfect solution for a County looking to manufacture their own blacktop material.

The County's source of aggregate comes from a quarry roughly 30 miles away from their maintenance facility, so the District Three crew simply stockpiles materials for when then need it. "When we need some asphalt, we just get a tanker load of oil and run off a batch. It's quite simple…we should start selling this to the other districts in our County!"

Porter's team needs only two people to run the plant, which is generating about 175 tons of asphalt per hour. Because of the ease of use of the KPI-JCI, and the lack of extensive maintenance requirements, Grady County did not need to add more labor to their costs of operations. "We just run it when we need it," adds Porter. "A big advantage is that we have it when we need it, so we don't have to tie up a crew. We're in road repair, not the asphalt business."

A year of use under their belts, Porter looks back and sees so many benefits that internalizing blacktop production has brought them, not the least of which is some insulation from the rising cost of petroleum. But while he quickly agrees that for economic reasons alone, the pugmill was a smart purchase, he sees another benefit as being possibly even greater. "It really comes down to the quality of the road repair," he admitts. "Before, a double-chip seal was about as good as it got for us, but we'd done a lot of these roads so many times that they were getting hard to make perfect. We were buying a pretty good quality asphalt, but the real advantage here is that we can make so much more of it. And with more inventory to work with, we can use so much more of it than we could before. Now, rather than simply patch up holes, we can completely recover a stretch of road."

As he thinks about it, Porter is puzzled that more Counties are not turning to this as a solution for themselves. "It just makes so much sense," he explained. "If you use blacktop in any moderate quantity, this makes so much sense now. The cost of chips has gone up tremendously since we installed our system, but even before all that took place, the difference between what we can make it for and what it costs it's still an advantage to invest in this equipment." Porter estimates that in the course of just a year's worth of blacktop production, the investment has already been covered.

That leaves the roads in Grady County, particularly those in Porter's District Three, smooth and solid. For the roughly 50,000 people who live there, it ensures an attractive community and an easier way of life, in harmony with the heavy industry that helps drive the economy of their county.