Connected fleets for off-highway rental products are cautiously making their way into our industry. Telematics isn’t a new concept for fleet management companies, we’ve been hearing about the advantages for over a decade now. What’s new is the improved ROI on the solutions available for off-highway fleets. If you find that most of these statements would add value to your processes, then it might be time to speak with an expert about how you can connect your off-highway fleet.

Mixed fleet friendly

A common concern about OEM delivered telematics solutions is that they are proprietary, which would mean greatly reduced value to mixed fleet rental fleets. The idea that a fleet manager or service technician would access 10 different portals for 10 different makes of machines is non-starter. Telematics is at its best when it’s making business simpler and faster. That means rental companies need a solution that doesn’t deal with mixed fleets as a burden, but as an opportunity to connect.

This is why we at Skyjack chose to partner with a telematics provider that had the most experience integrating mixed fleet data into one easy to access system. Using Trackunit’s infrastructure to power ELEVATE, Skyjack’s telematics solution, means that our customers will be able to benefit from a true mixed fleet solution and manage their entire fleet through a single solution provider.

Combining this kind of flexibility with the other advantages of OEM delivered telematics makes ELEVATE the best option to build a connected fleet.

Hours and location aren’t enough

Third party telematics solutions often provide a basic hours and location report on each unit. These are great data points that provide value for logistics operations and on-road fleet management, but aren’t as valuable for off-highway construction machinery in terms of service and ready-to-rent inspection.

For many categories of construction machinery, run hours and location aren’t mission critical data points, and they don’t provide you with enough value to justify the cost of incorporating a telematics solution. When you consider a high volume machine like a 19 foot electric scissor (e.g. SJIII 3219), this relatively low cost high volume machine will be responsible for a significant amount of service calls due to the high number of them in the field. These machines are stationary (or don’t travel very far), and run hours don’t give a good indication of their health. So here we have one of the highest impact machines when it comes to service and fleet management, but it doesn’t benefit from the basic telematics data.

OEMs have the opportunity to specialize telematics to their machines and machine categories. When done right this means delivering data that saves cost and critical resources for an off-highway fleet. ELEVATE provides value to our customers by delivering data that leads to increased utilization, better planned service, precision billing, and monitored usage.

Telematics engineered from the machine outward

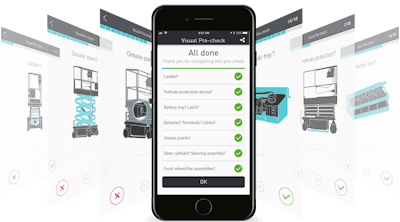

Connectivity can’t be an afterthought. Slapping a black box on a machine after production to gather whatever data happens to be available leaves you with the wrong data points, at a higher price. Connectivity shouldn’t be treated as an add-on, but rather as a fundamental component of the machine. This is why at Skyjack when we’re looking at machine design we’re asking the question “how does this improve connectivity, and what problems can that solve for our customers?” That means that machines are engineered with components that deliver key data points to our customers and provide them with data that can simplify service, fleet management, and have a clear impact on safety and profitability.

When you design the platform, or the scissor stack or the wheels of a lift, you’re always asking how these components fit into the overall customer experience of the product. How do those rails make the machine, that stack more efficient, or the wheels more stable? Each component is a fundamental part of the machine’s value to the customer, and to best benefit the customer machine connectivity needs to be treated the same way.

Only by involving the OEM, who designs the machine from the ground up, can you expose the most important machine data to the customer and end user.

A pricing model that makes sense

The ability to integrate telematics as a true fleet management solution for off-highway requires fleet-wide adoption (or close to it). This means that any telematics service needs to be priced in a way that can feasibly be applied to lower cost, high-volume machines like electric scissors, light towers, and skid steers. The cost reduction that comes with integrating a telematics installation into in factory machine production plays a key role of lowering that cost.

Aftermarket installation of telematics solutions means paying for potentially costly in-field installation by service personnel, or the telematics company itself. The ability of an OEM to professionally fit and install telematics solutions as part of the machine assembly process eliminates the majority of that cost. In addition, the cost of the data service can be discounted as part of the larger machine sale.

At Skyjack we’ve approached telematics as an opportunity to make our machines easier to service, and a way we can continue to deliver on our easy to do business with philosophy. We’re ultimately in the business of selling and servicing machines, and telematics should make our existing goals as an OEM easier to attain – those goals being customer satisfaction, low cost of ownership, simple and reliable products – and do the same for our customer’s and their goals.

The key is for OEMs to approach telematics as something to enhance their existing product line, rather than a new product line itself. With ELEVATE Skyjack has taken that approach and we’re seeing engagement from new customers and immediate inclusion into fleet management processes as a result.

The author, David Swan, is product manager, technology and innovation, at Skyjack.

![Herc 5745c08a34274 1 65ce4101dd187[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/06/herc5745c08a34274-1-65ce4101dd1871.UqeKvSiS04.png?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)