Concrete specifications often require the concrete contractor to submit a cold weather concreting plan. A good plan ties the submittal to cold weather requirements in the specification and can help you to avoid having unnecessary requirements imposed on you. Plan details are the key. Including inadequate detail can result in rejection of the plan, but including too much detail can sometimes reduce your cold weather options. The plan should simply describe the means and methods you intend to use in meeting the specification requirements. Submitting the plan and having it approved by the engineer of record provides a written record of your intentions, which can settle a lot of arguments before they start. The only caveat: Don't put anything in the plan that you aren't prepared to do.

ACI 306.1-90, "Standard Specification for Cold Weather Concreting," is a good starting point for preparing the plan. Section 1.5.1 of this document states the following:

"If required, submit detailed procedures for the production, transportation, placement, protection, curing, and temperature monitoring of concrete during cold weather. In the submittal, include procedures to be implemented upon abrupt changes in weather conditions or equipment failures. Do not begin cold weather concreting until these procedures have been reviewed and accepted."

Plan introduction

Introduce your plan with the following statement: This Cold Weather Concreting Plan is submitted as required by the Project Specifications and conforms to the requirements established in ACI 306.1-90, "Standard Specification for Cold Weather Concreting," available at www.concrete.org. It's a good idea to also define cold weather so there are no arguments about when the plan must be followed. ACI 306.1-90 defines cold weather as follows:

"A period when for more than three successive days the average daily outdoor temperature drops below 40 F. The average daily temperature is the average of the highest and lowest temperature during the period from midnight to midnight. When temperatures above 50 F occur during more than half of any 24 hr duration, the period shall no longer be regarded as cold weather."

Production

Discuss the details of cold weather concrete production with your concrete supplier. Some suppliers have a written plan that you can use, but you may want to read the plan, then use only some sections from it in your plan. Describe the means to be used for meeting requirements for the minimum and maximum concrete placement temperatures shown in the table below. These may include heated mixing water or aggregates or both.

The commonly specified duration of protection period for concrete exposed to freezing is three days, but this can be reduced to two days if the rate of early strength gain is increased by one or more of the following:

- Adding an accelerating admixture

- Using Type III cement, or

- Increasing cement content by 100 pounds per cubic yard

Any combination of these methods is acceptable, so discuss the most economical method(s) with your concrete supplier. If specifications allow the use of calcium chloride as an accelerator, selecting this option is usually the most economical and efficient way to accelerate both setting time and early strength gain. If only nonchloride accelerators are allowed, changing cement content or type may be more economical. Describe the method(s) to be used in your plan.

Transportation and placement

Generally, concrete can be produced at a high enough temperature at the plant so no special methods are needed to insulate the concrete truck drum. If the concrete will be placed by crane and bucket, pumping, or conveyor very low air temperatures may necessitate steps to ensure that the placement temperature doesn't drop below the allowable minimum. Scheduling deliveries that reduce truck waiting time is the least expensive way of achieving this goal. In the plan, tie the temperature measurements to the action to be taken if the placement temperature falls below the specified minimum.

Because concrete must not be placed on a frozen subgrade, means for thawing the subgrade must also be described. In some cases, covering the surface with insulating material for a few days may produce acceptable thawing, but it may be necessary to apply heat. In the plan, describe the methods to be used for insulating or heating the subgrade.

Protection

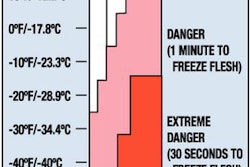

Materials for protection may include insulating blankets, enclosures, means for heating enclosures, or a combination of these protection methods. The number of insulating blankets needed to supply a required R-value must be on hand. Materials used to build heated enclosures must also be on hand: plastic sheeting, lumber, vents, and hardware. Combustion or electric heaters may be needed, and proper venting will then be required for combustion heaters. Wood forms may be left in place for walls or other vertical concrete, but if the forms must be cycled quickly, enough blankets may be needed to cover the concrete for the duration of the protection period. Describe the proposed protection methods for different temperature ranges. Make sure the plan addresses all concrete elements that might be subject to cold weather, including slabs on ground, walls and columns, and elevated slabs. A separate cold-weather mix may be required for different elements.

Curing

The plan should indicate the method to be used to prevent concrete from drying during the required curing period. Water curing is generally discouraged because concrete should not be at a high moisture content when it is exposed to freezing temperatures after the protection period. Insulating blankets serve the dual purpose of keeping the concrete warm and preventing moisture loss. Leaving wood forms in place for walls or columns can also be a part of the plan. Indicate if curing compounds will also be used.

Temperature monitoring

Indicate in the plan how temperature measurements will be made at the concrete plant and point of placement. Specifications usually require measuring temperature at the concrete surface at regular intervals to ensure that the concrete gains the strength needed before protection is removed. Your cold weather plan should indicate the general locations of temperature measuring devices having an accuracy of ± 2 F and the frequency with which the temperature measurements will be made.

When curing and protection are discontinued, specifications also require a gradual decrease in surface temperature to minimize thermal stresses that might cause cracking. Your plan should indicate how you will allow the concrete to cool so the maximum cooling rate isn't exceeded.

Abrupt changes in weather or equipment failures

Indicate in your plan the weather services you will monitor to predict local weather changes. Also briefly describe any backup placing and finishing machines, heaters, or other equipment that you'll have on hand in case of breakdowns. A procedure for installing emergency construction joints can also be added.