Since the early 1970s, environmental professionals and health experts have called attention to contaminant vapor intrusion and have alerted the public to the serious health problems caused by poor indoor air quality.

Beginning with radon, the understanding that chemicals could enter occupied spaces and cause adverse health effects has steadily expanded over the ensuing decades. It is now widely known that hydrocarbons and industrial solvents are commonly found on brownfield properties where former industrial sites once operated – many of which are now undergoing redevelopment within major metropolitan areas. Even in very low concentrations, these compounds can pose significant health issues, such as cancers and birth defects.

In order to safeguard human health, it is necessary to prevent vapors from entering occupied spaces, but it was not until recently that a vapor barrier was created specifically for that purpose.

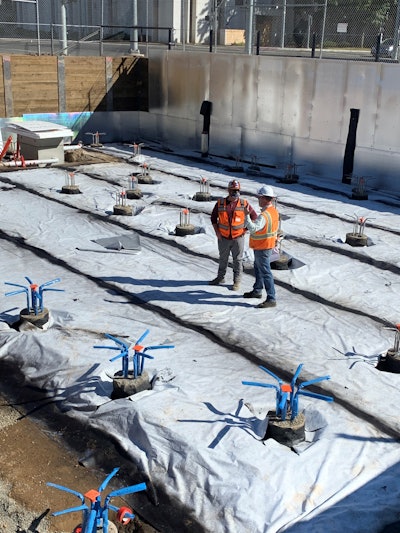

Installation of a TerrShield barrier in downtown Sacramento as part of a large brownfield redevelopment project.REGENESIS

Installation of a TerrShield barrier in downtown Sacramento as part of a large brownfield redevelopment project.REGENESIS

Looking to create a better, safer and more long-term solution, scientists and engineers have been conducting intensive scientific research and development to create a first-of-its-kind suite of safe, cost-effective passive vapor barrier systems designed specifically for vapor intrusion. To do so, they examined two main components — the base layer and spray-applied seal — and reimagined them from the ground up.

Metallized Films

To upgrade the base layer, vapor barrier scientists decided to incorporate aluminum, which is well known to be able to prevent the permeation of organic volatile compounds. By sandwiching it between layers of flexible polyethylene, they developed an easy-to-install base layer with chemical resistance 100 times higher than the simple waterproofing sheets composed of high-density polyethylene (HDPE) used in the past.

Installation of a TerrShield barrier in downtown Sacramento as part of a large brownfield redevelopment project.REGENESIS

Installation of a TerrShield barrier in downtown Sacramento as part of a large brownfield redevelopment project.REGENESIS

After evaluating several potential options, scientists developed a Nitra-Core spray-applied barrier material, designed to replace SBR-based latex waterproofing material with nitrile, a key component of chemically resistant personal protective equipment used in handling hazardous materials (e.g. blue disposable gloves).

Studies comparing the chemical resistance of the new nitrile-advanced asphalt barrier material to generic latex-asphalt barriers determined the nitrile-advanced material to be 10X more resistant as a contaminant vapor barrier against the common industrial solvent contaminant trichloroethylene with the generic asphalt-latex material allowing 10X more contaminant vapor diffusion across the barrier.

Land Science, a division of REGENESIS

Land Science, a division of REGENESIS

In addition to the increased chemical resistance, both the base layer and spray-applied seal were designed to be easily installed, thus reducing construction timelines and saving money. They were also built to withstand the stresses of a construction site both during installation and afterwards (i.e. foot traffic, heavy equipment, and the occasional dropped tool), thus preserving its structural integrity and maintaining its efficacy.

An Evolution in Vapor Barrier Technology

Instead of just repurposing inferior technology that was developed for a different industry, scientists and engineers understood that in order to effectively tackle the issue of vapor intrusion, they needed to approach the problem with a full understanding of its challenges to effectively meet the needs of the environmental professionals tasked with guarding human health. The ideal vapor barrier would be easy and quick to apply, physically tough, and chemically resistant.

Through the innovative use of barrier materials such as aluminum and nitrile, researchers have created a suite of barrier systems that meet all those criteria and, unlike the vapor intrusion solutions of the past, are specifically designed to handle the vapor intrusion problems of today.

- Part 2, “An Easy & Fast Install” can be found at ForConstructionPros.com/21200081

- Part 3, “Safety” can be found at ForConstructionPros.com/21200084

Land Science, a division of REGENESIS

Land Science, a division of REGENESIS