Concrete contractors and general contractors who self-perform concrete have been challenged with a lack of skilled labor. From the starting positions on the crew to the experienced – the most common criticism is that “no one wants to work anymore.” Yet, based on the advancements seen during World of Concrete 2025, its more on safety, security, and growth - being an effective part of the team.

Could it be more about getting the job done productively and efficiently (let’s throw “right” in there for good measure) than a sore back the next morning? Manufacturers know you’re running a skeleton crew. The innovations at the show were designed to help make that crew as strong as possible. World of Concrete was held in the Las Vegas Convention Center on January 21 to 23 with educational days prior to the tradeshow. World of Concrete 2026 is scheduled for January 20-22, 2026 with education starting on January 19.

Cutting & Drilling

Known for blades and drilling solutions, Diablo came to World of Concrete to improve safety for concrete contractors “through doing the right thing to do.” Their advancements include a new anti-vibration formula to allow a clean cut to reduce the blade’s wobble in a circular saw, a metal cutting blade for that same circular saw, limiting the amount of burning in demo blades, a few new reciprocating blades for further demo/cutting work, and reducing the dust when drilling concrete.

In World of Concrete 2024, Diablo launched its AMPED Rebar Demon SDS-Plus 4-Cutter Full Carbide Head Dust Extraction Hammer Drill Bit. Essentially, it was a sleeve that helped extract dust and limiting the need for contractors to go back and forth cleaning out the unwanted debris. They say they improved the solution by extracting even more dust “away from the jobsite, away from the end user.” The idea is to allow contractors to move to the next step whether it be another hole or an epoxy anchor quicker.

As expected, the big-name power tool brands added new assets to their platforms. Bosch, for one, announced a dry-cutting chop saw bringing a 14-in. blade to the jobsite to help contractors more easily cut bundles of steel rebar. Other concrete-specific introductions included metal angle grinders, a 5-in. 18V deep cut band saw, an 18V brushless 9-in. cutoff saw, and a concrete mixer handle that is expected to be out in the summer (a “mud mixer” will be available in February 2025, but it was designed for mortar, paints, epoxies, etc.)

Milwaukee Tool now features 25+ tools on their MX FUEL line plus, they continue to build out their light equipment solutions powered by the Forge battery platform. They continue to reach out to areas of the jobsite they didn’t reach before. New for Milwaukee is a NITRUS framing and demo 7 ¼ in. blade for circular saws helping concrete contractors breakdown form material embedded with nails. (Expected availability June 2025.) Also on the forming construction side is a new duplex nailer and rebar cutter, both powered by the M18 battery.

Hilti’s announcements included two new concrete saws, the DSH-600-22 and 700-22. They also finally cut the cord on their DD-150 U-22 core rig on the NURON platform (which now features more than 100 tools in four different sizes). Rest assured, contractors will be able to use their DD 150 stand if they already have one. Don’t forget to get some assistance with the strenuous job of holding up equipment with their battery-powered EXO-T, designed to transfer weight off the shoulders and arms to the hips.

Moving Material

Brokk announced that they’d be distributors for First Green, Darda, and Ecovolve companies – each aligned toward the efficiency of the concrete contractor to keep getting work done with solutions to fit the jobs at hand. We got a close-up look at the Mini Z400 and its big sister ELISE 1200 from First Green (roughly 8-10X more powerful than the Mini). In order to make the Mini Z400 fit through a 32-in. doorway, First Green moved the hydraulic motors to later int eh powertrain of the machine. They also say this provides them with some more efficiency. Battery-powered, the machine should put out 6-8 work hours depending on the job. They have 40+ proprietary attachments but a coupler should allow contractors to also continue to use Toro Dingo and/or Bobcat attachments.

EcoVolve’s three-wheeled battery-operated buggy gives contractors 10-12 work hours in one charge. The EcoChute 800’s compact design also fits through a 32-in. doorway. Larger models (1,000 and 1,800) are also available. The three wheels allows it a zero-turn radius.

Toro continues to move manual repetitive motions that often result in injury to machines. They debuted a small fleet of electric tracked machines. At 31.5 in. wide, the new battery-powered 750 eDingo opted for tracks to move over rough terrain. The Ultra buggy e2500 TS buggy dumper features a swivel that can spin 180 degrees to place concrete where it’s needed. The e2500 THL is a lift dumper capable of lifting 1,250 lbs. to 6 ft in the air – up and over the standard height of a 30-yard dumpster. (It’s max capacity is 2,500 lbs.) All of these models now only follow the Dingo platform to keep operator familiarity with the controls but fit through a standard door width. Toro says they are taking orders now and expected to ship summer 2025.

Tech

If there’s a place in construction that presents the most potential in addressing skilled labor shortages, it’s technology. And the folks at Trimble / Tekla are well-known for their solutions. Integrating technology like theirs not only can help layout and plan projects from real-life to a virtual product, but doing so increases the effectiveness of your team. For example, they brought in a CASE CTL on display to show off how the full integration of their technology can help operators with machine control technologies.

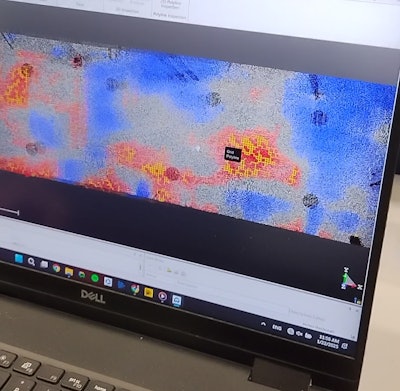

One of the more eye-catching demos was their 3D scan of a concrete slab to help identify the highs and lows. For projects that need high FF numbers, this can be a valuable tool to have.

You can’t talk about technology without including drones. Lucid Bots brought their solution from the building washing industry to concrete contractors. Their drone is outfitted with a nozzle that would stream a cleaning agent onto a building high up in the air. They took that idea and applied it to the sprays and coatings for contractors. Instead of a team manually pumping and spraying a slab, their drone can be easily programmed to fly the course. In essence, this directly addresses labor right on the site – allowing contractors to place their team on a different project or merely maximize the effectiveness of one employee.

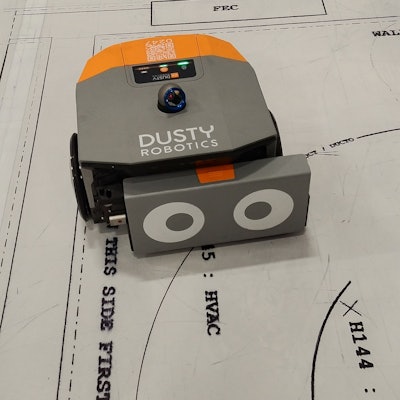

Dusty Robotics also utilized a robotic platform, albeit keeping it on the slab. Instead of flying, their robot “Dusty” is designed to increase the efficiency and productivity of all trades by taking the digital plans and printing them out on the floor. This removes the guess work and hours of snapping lines to locate tilt-up panels or spots to core out for future piping.

Similar to 3D scans, Dusty even provides a read-out of any high/low spots on the concrete that may require additional grinding.

Not only do volumetric trucks, such as those from Cemen Tech, place control of concrete in the contractor's hands (especially in the winter/summer months), but they also allow contractors to pour when they need, and pay only for what is needed. The company also updated its fleet management software ACCU-POUR with new features – many of which assist in managing contracts, invoices, and more. Expected to be available near the end of Q1 2025, ACCU-POUR 2.0 will allow contractors to enter and manage your entire fleet to gain more control of your inventory of both machine and material.

The idea is to move away from the dry-erase board or complicated spreadsheet to make the job easier and more efficient. Isn’t that the idea behind every item mentioned in this tour?

![Adobe Stock 350182902 1 6759c43d679ca[1]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2025/02/AdobeStock_350182902__1_.6759c43d679ca_1_.67b78c75671e9.png?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)