Using backhoes and excavators on sites to lift and place heavy construction materials saves time and money, but doing the job safely demands special care.

“A variety of concerns come into play,” says Kevin Hershberger, senior market professional for backhoe loaders at Caterpillar, “Including potential trench cave-in, lifting capability of the machine, visibility of the operator to the entire work area, modulation and controllability of the machine, skill level of the operator, condition of the lifting tackle and stability of the machine, to name a few.”

1. It’s critical to ensure the machine is rated to handle the load.

Exceeding the machine’s capacity can cause a project delay if the machine fails to make the lift, and the machine may also become unstable, creating a hazard.

Interpret the Surprises in Your Backhoe’s Lift Chart to Place Big Loads Safely

“Instability is an obvious concern because tipping could lead to injury or damage to the machine, site or payload — all of which are costly,” says Katie Pullen, brand marketing manager for Case backhoe loaders. “Lifting that extra load also puts undo stresses on the machine, which can lead to maintenance issues or failures.”

Overloading the backhoe or excavator for a lift can also damage the jobsite and/or load. “And then you have to factor in those downtime and repair costs,” notes Philippe Bisson, brand marketing manager, excavators, Case Construction Equipment. “It’s ultimately not worth it.”

“The proper machine provides sufficient lift and reach to place the material where needed,” says Louann Hausner, backhoe loaders marketing manager, John Deere Construction & Forestry, “While maintaining stability and control at all times.”

2. Make sure operators are thoroughly trained to read lift charts for the machines they operate.

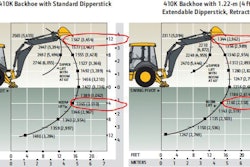

Even a machine with enough maximum capacity to lift a load can be overloaded in much of the boom’s working range.

“Lift charts can be confusing when they show several numbers on a page to depict changes in weight limits through a lifting arc or when loads are rotated from the machine centerline,” says Ray Peterson, founder of VISTA Training. “In the case of some crawler excavators, the lifting capacity from the sprocket end of the undercarriage to the idler end may vary slightly. And it [lifting capacity] will always be affected — for both crawler excavators and rubber-tired backhoe loaders — when picking over the side.”

Machine capacity is constantly changing, depending on where the boom is in its working range. The equipment manufacturer’s lift chart designates the safe lifting capacity at various boom angles, lift heights and swing radii.

A load can get out of control quickly if lift charts aren’t followed. “For instance, a load that may be safe to handle directly behind the machine might be unsafe if the operator would swing to the side,” Hershberger points out.

“Lifting over the side of either a backhoe loader or a rotating excavator changes the balance point,” Peterson explains. “This, along with extending the load further from the center tipping point, may lead to sudden loss of load control.”

“Training operators to the capabilities of their machines should be part of the very first instruction they receive before being given the controls,” Bisson emphasizes. “Equipment owners should also ensure that machine capacities are clearly posted or available in the machine for reference throughout the day.”

Make sure operators can identify rated lift capacities at various positions around the machine. “By knowing these limits and conditions,” says Hershberger, “the operator can ensure that he sets up to maneuver the load to an area of increased safety.”

3. Before lifting, inspect the machine to ensure there is no damage or other factors that could impede lifting capacity.

Check the surrounding area for obstacles or hazards within the lift zone. “Be mindful of utilities and other overhead obstacles that might be present,” says Bisson.

4. Make sure the machine is positioned on a stable work surface, as far back from the edge of any nearby excavations as possible.

“Be aware of the ground conditions prior to the lift and if loose material is present beneath the machine,” says Kent Pellegrini, product application specialist for excavators at Caterpillar.

Always lift over the idler end of the tracks when lifting with an excavator, and make sure the machine is positioned where tracks are stable with no voids or soft ground underneath. That could cause the machine to rock.

“Material built up under the front idlers helps if the ground conditions are soft to maintain a level lifting surface,” Pellegrini suggests.

Of course it’s best to avoid soft underfoot conditions, if possible.

“Be careful about wet environments,” adds Bisson, “especially in the spring, as the thaw can liquefy what may otherwise seem like a good operating surface.”

If you have to work from underfoot conditions with marginal stability, use mats, wood platforms or steel plates to provide a more solid work platform.

“Having a solid footing with the strength to support the machine is imperative,” says Hausner. In addition to the obvious safety concerns, lift capacity can be affected. “A machine on flat ground will have higher lift capabilities than a machine positioned on a slope. Soft or unstable terrain can also reduce lift capacity.”

If there are any doubts, perform a test lift. “Because raising the load reduces machine stability, especially on slopes or soft terrain, performing a test lift is an excellent way to gain confidence in machine stability and hydraulic capability,” says Hausner.

5. Once the machine is properly positioned, it should be set up for maximum stability and lift capability.

“In the case of a backhoe, both stabilizers should be placed down so that the tires are lifted slightly off the ground,” says Katie Pullen, brand marketing manager for Case backhoe loaders. “The point of having the tires off the ground is to eliminate the floating or instability that can be caused by pneumatic tires.” The loader bucket should also be placed on the ground for further stability.

Avoid lifting the tires too far off the ground, as it raises the machine’s center of gravity and narrow’s the outriggers’ footprint.

If operating an excavator equipped with a blade, the blade should be placed on the ground for stability. Also make sure the proper counterweights are in place.

“If you’re ever working with a compact excavator with retractable tracks — which are not generally recommended for lifting and placing — it’s important to remember to only operate with the tracks fully extended out,” says Pullen. “Tracks should only be brought in for fitting through tight areas, and the machine should always be used with the tracks extended.”

6. Clear the area of any workers.

“When lifting material on a jobsite, a contractor must confirm that all bystanders are out of the swing radius of the boom to ensure employees are protected from falling objects,” says Hausner.

Bisson adds, “The only person recommended in the immediate area is a spotter who signals important information to the operator, and that person should be stationed well clear of the lift taking place.”

7. As you’re performing the lift, keep in mind that a machine will always have its highest lifting capacities closer to the machine.

“As much as the jobsite allows, always keep the load close to the machine as you move it, and then extend it out to place it in the desired location vs. extending it out and then swinging it,” Pullen advises. “This method will ensure more stable operation.”

8. Slow movements are stable movements.

“Slow, deliberate motion during lift and placement helps ensure a controlled operation,” says Hershberger.

9. When selecting rigging for the lift, check its load rating.

“Some people will attach straps for a lift because it’s what they have available, but that strap may only be rated for 100 lbs., or 2,500 lbs. — and the piece they’re lifting is 3,000 lbs.,” says Pullen. “Always make sure the rigging is rated to handle the load.”

Rigging must also be suited to the application.

“For example, it is not safe to use chains designed for equipment transport in a load lifting application,” says Peterson. “And chain used for lifting loads should never be used to tie down equipment for transport.” Nylon web slings should not be used to pick items that may have sharp edges and could damage the sling. “Conversely, using chain to lift bundles of rebar will not provide as much slip resistance for long lengths as a double basket hitch with nylon web.”

Material being lifted often dictates the type of rigging required.

“For example, picking bundles of materials such as rebar or various types of pipe may require a single or double basket hitch using web slings, while lifting some precast concrete items may demand multiple-point securement using chains or wire rope with clevis attachment devices or special clamp-and-pick tools,” Peterson explains. “How each type of lifting sling is attached to the load, as well as to the machine doing the lifting, is critical.”

10. Know the condition of the rigging.

“The rigging should be inspected before each use to ensure there are no signs of damage or wear,” says Hershberger.

See the Rigging Information section of The Crosby Group's 2014 General Catalog

11. Always ensure the load is properly secured to the carrier.

“Proper lifting equipment, which includes latching hooks, helps ensure the load will be handled safely,” says Hershberger.

“You’ll see on some jobs the chain simply being attached to a bucket’s tooth, or to the edge of the bucket,” Pullen comments. “Be it a strap or a chain, rigging should always be properly hooked to the machine. In the case of an excavator, that’s making sure it’s hooked to the load-handling eye on the bucket or coupler. For a backhoe, that means it’s properly attached to the lifting hooks on the loader bucket, or to the lifting eye (usually an attached clevis hook) on the backhoe arm.”

Ways to secure a load vary.

“It all depends on the type of load, and if there is a single-point lifting eye or multiple points,” says Pullen. “Take a trench roller, for instance, [which is] commonly lifted into trenches by excavators. There are four lift points on it, and it’s an articulated machine. You have to make sure that the articulation joint is locked and that all four points are connected so that it’s not going to tip, spin or wobble. If you’re lifting and placing a pallet, make sure that it’s properly banded and secured.

“Bottom line: Take advantage of all available lifting points to ensure load stability,” she advises, “and then make sure that the load is secured so that it cannot shift or come apart during the lift.” ET

12. Also take precautions, as needed, to minimize the risk of sudden shifts while moving the load.

“Many loads should have one or more rope taglines attached for persons to help control the load from swinging and swaying, which may result in stresses that can overload the lifting device or cause machine upset,” says Peterson.