Horizontal directional drilling (HDD) is challenging and difficult work fraught with unknown obstacles. While it's not possible to eliminate every obstacle, bore planning software tools developed by drill manufacturers can help small and large contractors create a bore plan that may help minimize risks.

Bore planning software was first introduced 15 years ago. However, these software programs were very basic and helped the contractor design only the pilot bore. While the software helped streamline the planning process, it was still time consuming and not widely used by contractors. Many would just drill and hope the bore was a success.

Today, bore planning software packages are more intuitive and user-friendly. The time to create a bore plan has gone down dramatically, and these programs provide the contractor more information than ever about the bore and pullback. Bore planning software helps remove the guesswork related to determining elevations, estimating the drill pitch for the pilot bore, mud volume required, and how hard the pipe will pull.

"These days a contractor simply needs to gather the topographical elevations and required depth along the bore path, enter the data, hit Plan and the software program will produce a rod-by-rod plan of your bore," says Curt Dubbin, a trenchless solutions specialist with Vermeer Corporation.

In the past, it seemed that the software tools were being used on only the larger pipeline bores. That is changing as more projects in the mid-sized range, 24,000 pounds (10,886 kg) and up, are beginning to use these tools as well for on-grade and profile bores.

Another reason for their increased utilization — avoiding existing underground facilities and record keeping.

"Bore planning tools can also be used to help contractors develop a bore plan that will maintain proper separation distances between underground facilities," says Dubbin. "This is becoming ever so important as the vast amount of underground infrastructure continues to grow. Many of the software applications also allow you to create a permanent record of the completed bore that can be used as a reference to help generate more accurate bids on future jobs."

Planning easy as 1-2-3

There are a number of bore planning software programs on the market and each has a definite role in the bore planning process. Following is a quick summary of what's available to HDD contractors:

Analysis — Software programs exist that help contractors and engineers determine whether open-cut trenching or HDD is appropriate for the installation. Nine different aspects are considered, including customer expectations, familiarity with technologies, project location, soil sample reports, competitors and risk factors. The software provides a detailed analysis and various considerations for choosing either method and explains its recommendation.

Pre-planning — These software tools help the contractor select the appropriate drill and tooling based on the type of pipe to be installed and the anticipated soil conditions. Contractors can use the pulling load calculator to calculate the required pulling load for a specific HDD project based on the type of pipe used, pipe diameter and total bore length. The calculator will also recommend the appropriate size of drill based on the bore specification entered for the project. A soil classification guide helps contractors determine the project site's soil type and match the appropriate drill bit and backreamer. It also includes a fluid-mixing process map that shows how much mud should be used based on soil conditions, drill unit and tooling used.

Terrain mapping — This is the survey phase where laser systems are used to collect accurate topography and existing utility information along the bore route. In most software applications, this information can easily be uploaded to the bore planning software.

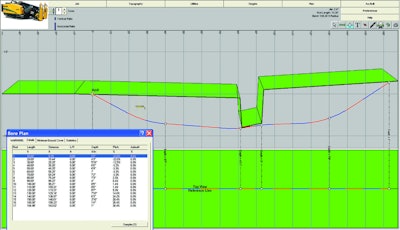

Bore planning software — Using the data collected in the mapping phase, these programs provide a graphic visualization of the job, helping a crew see and perform the job from start to finish. By choosing drill stem diameter and length, desired bore path depth, desired minimum cover, diameter and allowable bend radius of the product pipe, the software plots a proposed bore path. The bore path is provided in two formats, one screen showing a top and side view, the other showing a report that lists the numerical depth and pitch of each drill stem. Once the bore is completed the actual as-built depths can be entered into the designed profile and a comparison showing design versus actual can be graphically shown.

In-field calculations — We all know things can change once you're in the field and a number of drill manufacturers also offer handheld software tools just for these situations. These PDA devices can calculate setback distance, figure point-to-point bore paths, estimate pullback time and hole volumes and configure outside diameter of multiple ducts.

Changes on the horizon

While bore planning software has advanced by leaps and bounds the past five years, manufacturers are continually looking for ways to enhance their software packages and the trend is heading to more information.

"We are working to tie all of these applications into one complete package," says Dubbin. "This will provide the contractor with more in-depth information and data on proposed and completed bores. The software program will record how hard the drill is working on a bore, to mud pressures, to the amount of fuel consumed. A contractor will know exactly what happened on the bore and the cost."

From a contractor's perspective, with this type of data on a project, they can increase their knowledge base and use this data to more accurately bid projects and manage their business. This integration will also make the planning process easier for the contractor as well, rather than jumping from one program to the next and then trying to bring it all back together into one cohesive piece.

"Typically contractors record data on only larger bores, but just imagine the competitive advantage a small- to mid-sized contractor could have with this type of information," says Dubbin. "It could make a significant impact on their business."

Software is not just for contractors

While HDD contractors routinely use bore planning software in their business, Dubbin says engineers are also getting on board.

"I receive calls every week from engineers asking about our software programs," he says. "They are using these tools to better plan underground installation projects that take into account a directional drill's capabilities."

From time to time, engineers will design directional drill projects that are not mechanically feasible. The plans will call for a bend radius that is just not possible or propose using a machine that may be underpowered for a specific project. In addition, the industry is asking for more on-grade boring, and the software is designed to help engineers develop these projects in a realistic manner.

Some communities also require a formal plan be submitted prior to a project commencing. In Canada an HDD contractor must submit a formal bore plan on all pipeline projects. Environmental guidelines do not allow for frac-outs on pipeline projects as a way to avoid the potential of mud entering a river or wetland area. Contractors are required to submit a plan that includes estimated mud pressures below ground and have a plan in place to monitor downhole pressure to avoid potential frac-out situations.

Not every situation can be planned

Dubbin also stresses caution when using bore planning tools as unforeseen obstacles can always sidetrack a well-planned bore.

"You can't see what is happening down in the ground during a bore so you never know what may happen," says Dubbin. "There are a lot of variables that a person can't control so it helps to be prepared."

One factor that can be difficult to prepare for is changing ground conditions. Dubbin encourages drill operators to watch the returns on a pilot bore. The colors of the returns will provide you with an idea of the type of soil you're in. If the returns are brown, and all of a sudden they turn to a really dark brown, or if they turn to light white or gray, you're entering a different soil.

The different soil type may require additional mud. You will need to pump three to four times as much mud into clay, as it takes more force to remove the dirt particles from the hole. This is something the bore planning tools cannot predict. This also applies to drilling in rock, because a 20,000 psi (1379 bar) rock will drill much different than a 42,000 psi (2896 bar) rock. However, core samples along the bore path can be extracted and factored into the plan. This way you will know rod-by-rod when you enter and exit those unique rock formations.

Practical use in the field

Erv Hoge with Earth Energy in Boise, Idaho, understands the value of bore planning software and how it has helped his company. His horizontal directional drilling company specializes in utility installations — the kind most contractors would shy away from.

"We deal with some pretty challenging bores and our planning software is a huge asset in our company," says Hoge. "Seven or eight years ago, we had to create our bore plans using hand levels, tape measures and creating the bore path by hand. It required considerable time, but with lasers and our Atlas Bore Planner® software from Vermeer, it's much easier and efficient to map the topography and design the bore."

Earth Energy documents every bore they complete, whether it's a 30- or 1000-foot (9.1 to 305 m) bore, using a combination of the planning software and bore logs. Many times the company has been hired to go back and complete a bore at the same area.

"The bore logs and planning files are a great help in determining where we put the previous bore, what utilities we encountered in the first bore, where existing utilities and what depth we bored," says Hoge. "The information is great to share with a customer and it helps us better estimate the cost of the project."

Earth Energy tracks the depth of every rod and sometimes every half-rod. The crew follows along the bore plan profile to track any variances. In the end an as-built is created and compared with the design.

"The software takes the guesswork out of the planning process," says Hoge. "If we try to design a bore too short and too steep for a particular drill, the software will flag the problem and walk us through the steps to correct the situation."

For Hoge the bottom line is pretty simple.

"Bore planning software helps save our company time and money," he says. "More importantly it helps us account for unforeseen challenges before they become a reality. That confidence is worth a lot to our company and our customers."