The average driver can usually see when pavement deterioration becomes problematic—there will be tearing or rutting on the surface of the road or cracking in wheel paths that decreases safety on the roadway. Underneath the surface of the pavement, however, the signs of deterioration existed long before they were visible and experienced by drivers. Delamination between asphalt layers underneath the surface of pavement is often due to layer debonding or stripping, which typically is not visible, especially in the early stages. Additionally, manual destructive methods for evaluating pavement problems can be time consuming and expensive for state DOTs and other transportation agencies.

State DOTs, however, have found ways to address these challenges through advanced technologies out of the second Strategic Highway Research Program (SHRP2), a partnership between the Federal Highway Administration, the American Association of State Highway and Transportation Officials and the Transportation Research Board. SHRP2 solutions are a comprehensive and data-driven set of products, procedures and best practices meant to help transportation agencies save time, money and lives through innovative solutions to common transportation challenges. One solution—Advanced Methods to Identify Pavement Delamination (commonly referred to as R06D)—features two nondestructive testing (NDT) technology systems that can spot problems in the asphalt pavement beneath the surface in a safer, faster, and less expensive way than previously done.

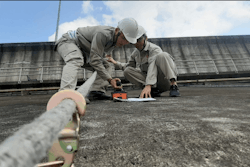

“Right now for state designers, the way to truly evaluate pavement is taking cores,” Stephen Cooper SHRP2 renewal pavements engineer and FHWA product lead for R06D says. “It’s a very slow process, and a destructive one. You’re also impacting the traveling public. The great thing about these SHRP2 NDT technologies is that they provide DOTs with information right away so they can identify those problem areas in advance so that we can then do some further examination and address the issues.”

Six state DOTs tested the NDT technologies included in R06D through the SHRP2 Implementation Assistance Program (IAP), which provided financial assistance and technical guidance from subject matter experts.

GPR Leads the Way

One technology included in R06D is 3D ground penetrating radar (or 3D-GPR). The 3D-GPR technology can detect certain delamination issues, using an antenna array with a frequency sweep that can be operated at highway speeds (over 60 miles per hour). The wide antenna array reduces the number of passes required to cover the lane width, allowing operators to cover larger areas at a time. The technology can also be used to gather other subsurface information, such as the location of utilities. Since the technology can be used at highway speeds, DOTs can utilize the technology in live traffic, eliminating the need for closures—a real benefit to drivers.

The 3D-GPR technology has the potential to be a helpful tool to identify moderate to severe distress as part of a systematic coverage plan of a highway network. GPR data analysis requires a skilled technician to identify distressed locations though as automated distress recognition software improves, the level of manual data analysis lessens.

“Pavement stripping is a big problem in Minnesota, so we were very interested in the 3D-GPR to effectively and reliably detect this deterioration in asphalt pavements,” Dr. Shongtao Dai, research operations engineer at the Minnesota Department of Transportation (MnDOT) says.

MnDOT used the 3D-GPR to collect measurements on multiple pavements, some located at MnDOT’s MnROAD test track. These measurements were evaluated and correlated with data from 200 cores taken in 2016. The results were encouraging, as the technology allows DOTs to pinpoint areas for further investigation, rather than a hit or miss approach.

However, the 3D-GPR does have its limitations. It cannot distinguish new debonding problems where the bond between the asphalt lifts is weak. For the technology to be effective, the asphalt layers being tested must be separated with air or water.

Still, the benefits are real for state DOTs. The California Department of Transportation (Caltrans) found that 3D-GPR made large area surveys more cost-effective. Caltrans experienced a 120:1 return on investment for data acquisition when compared to the experience of single-channel GPR systems. The Kentucky Transportation Cabinet (KYTC) had so much success with the single-channel GPR on several forensics projects (a $3.7 million in savings) that it is moving to the 3D-GPR system.

“We intend to adopt the 3D-GPR system in lieu of other single-channel radar systems on selected pavement rehabilitation projects in the future, with the hopes that the multi-channel unit will provide superior depth resolution and detail to that of a single-channel unit,” KTYC Program Manager Brad Rister adds.

Real-Time Results

The other technology system included in the R06D product is Spectra Analysis of Surface Waves (SASW) and Impact Echo (IE), two separate technologies used together to help identify the location of pavement delamination with automated test frequency every six inches in less than 1 percent of the time required by manual point testing. The software uses real-time display to monitor the quality of the data collection. IE identifies variations in the pavement, though improved analysis requires the hot-mix asphalt to be cool and stiff. SASW technology can identify variations in the top seven inches of pavement as long as the analysis uses a reasonable value for the stiffness of pavement.

Like with the 3D-GPR, there are limitations with these technologies. IE measurement has limited ability to identify exactly how severe the delamination may be and cannot measure pavement conditions below the first level of damage. SASW measurement also has a limited ability to show how severe the delamination is and is unable to measure pavement conditions below the first level of damage. This technology requires a lane closure, as it works at walking speeds.

Even with its limitations, state DOTs see how it could be helpful moving forward. Caltrans, which also evaluated the SASW/IE technology, sees value with additional time and work.

“We believe that SASW/IE hardware and software and show future promise and we will continue to monitor its development and revisit the economics of acquisition as the technology matures and additional data needs develop within Caltrans for pavement evaluation and monitoring,” Bill Owen, chief of the geophysics branch at Caltrans says.

The SHRP2 program comes to a close this summer, but as those who have utilized these technologies can attest, the R06D product including 3D-GPR, SASW/IE will continue to mature and gain popularity due to the opportunity to save time and money.

“By having more information about what’s underneath the pavement, states can make better decisions as to how they’re going to repair or rehabilitate those pavements,” Mike Heitzman National Center for Asphalt Technology Assistant director says. “This technology allows for that additional information, which could ultimately impact the bottom line of a transportation agency in a positive way.”

Additional information on the technologies included in Advanced Methods to Identify Pavement Delamination (R06D) is available at http://shrp2.transportation.org/Pages/R06D.aspx. To learn more about the technology systems and their specific uses, contact SHRP2 Renewal Pavements Engineer and FHWA R06D product lead Stephen Cooper at [email protected].