The theme of World of Asphalt 2015 is "Lay a Base for Innovation" and that is what Volvo Construction Equipment hopes to help contractors accomplish with their new Intelligent Compaction system with Density Direct. At an unveiling ceremony of the first day of the show, Volvo introduced the Volvo Intelligent Compaction (IC) system for select Volvo asphalt compactors available in two packages — Volvo IC and Volvo IC with Density Direct. In addition to offering the pass mapping, temperature mapping and data storage features of the Volvo IC system, Volvo IC with Density Direct includes the industry’s first real-time density mapping technology.

VIDEO: Volvo Density Direct Shows Real-time Density Measurements On the Roll

“Density mapping has been described as the ‘holy grail’ of intelligent compaction. The first to come up with the technology will be the one to radically advance the paving industry, it was said, and that’s exactly what Volvo has done,” said Dr. Fares Beainy, research engineer at Volvo Construction Equipment. “For years, contractors have relied on IC systems with stiffness calculations instead of density, which is not the true metric by which contractors are evaluated and paid. With Density Direct, operators have real-time access to the metric that ultimately determines the success of their work, density.”

Set the density and get to work

Within the Density Direct system is a calibration screen, where the user sets the target density for the project. Once fully calibrated with data specific to the application, the Volvo Intelligent Compaction with Density Direct system produces a density calculation that is accurate to within 1.5 percent of core sampling, providing a real-time reading of density values over 100 percent of the mat.

Brochure: FAQ's about Density Direct

With this real-time data, the operator is given the chance to make any necessary adjustments while asphalt is being paved. This not only reduces the occurrence of inadequate densities that drive up project costs, but reduces time spent taking core samples, improves quality, and leads to much greater uniformity than nuclear gauge testing. Calibrations are also “saved” by the machine, so operators can assign calibrations to certain elements of a job, and quickly switch back and forth between calibrations to meet the demands of specific job elements.

Operator-friendly interface

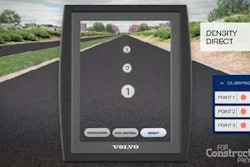

The user interface of Volvo IC with Density Direct depicts a density map, showing each square foot of rolled asphalt in a color representing density, and also provides a real-time numerical density reading displayed in the corner of the screen. Both Volvo IC and Volvo IC with Density Direct offer real-time temperature and pass mapping data. Using the 8"x10" color monitor of the Volvo IC system, the pass mapping function captures each compactor pass and drum overlap with an individual color, so that the operator can easily see gaps and work to maintain uniform coverage. Temperature mapping provides the operator with a temperature ‘map’ that shows the path of the compactor overlaid with the last recorded surface temperature.

Data storage and GPS

Data gathered from pass mapping, temperature mapping and density mapping is stored on the IC system’s internal 14 GB hard drive, which provides enough space for approximately seven months of data logging. Data can be backed up to USB drives in VEDA format — the Freeware system promoted by the Federal Highway Administration (FHWA) for IC systems. With optional Differential GPS, the data gathered from Volvo IC is linked to location information accurate to within 0.5 inches. Both Volvo IC packages meet state DOT and FHWA requirements for intelligent compaction specifications.

Independently tested and proven

Density Direct was developed and tested as part of the FHWA Highways for LIFE Technology Partnerships Program. The technology was used on various full-depth and overlay asphalt pavement projects and later evaluated by independent users at sites throughout the country. The results were overseen by University of Oklahoma researchers and showed that Density Direct calculations were proven to be within 1.5 percent of core samples every time at 180 test locations.

Brochure: Volvo IC with Density Directy

Availability in Q4 2015

Volvo IC and Volvo IC with Density Direct will be available in Q4 2015 on new Volvo asphalt compactors, initially including Volvo DD110B, DD120B and DD140B models sold in North America. Aftermarket availability for Volvo asphalt compactors will follow in the future, exclusively through Volvo Construction Equipment dealers.

Brochure: FAQ's about Density Direct